Superfine ruthenium nano-catalyst and method for preparing superfine ruthenium nano-catalyst in situ

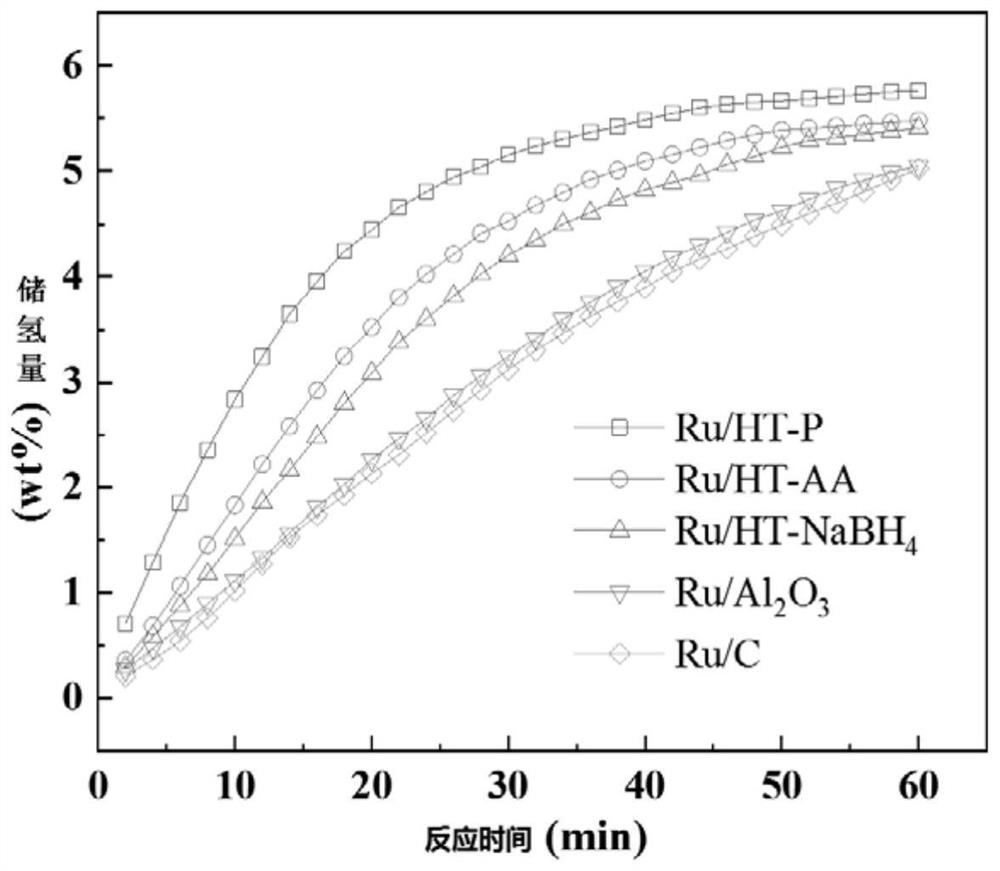

A nano-catalyst and in-situ preparation technology, applied in the direction of catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of nanoparticle agglomeration and low dispersion, and achieve high catalytic activity and dispersion Good, the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

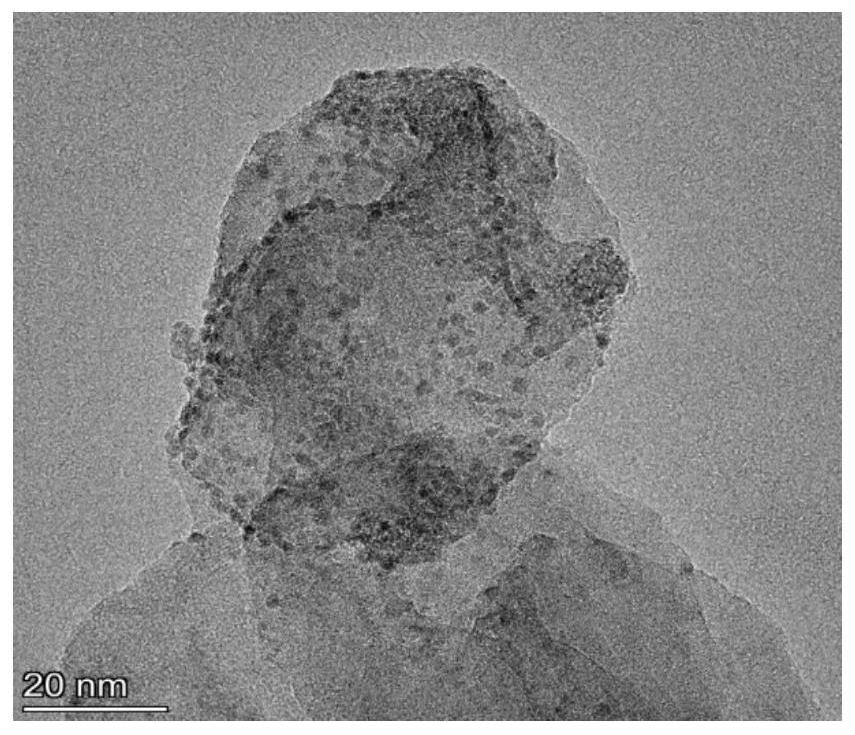

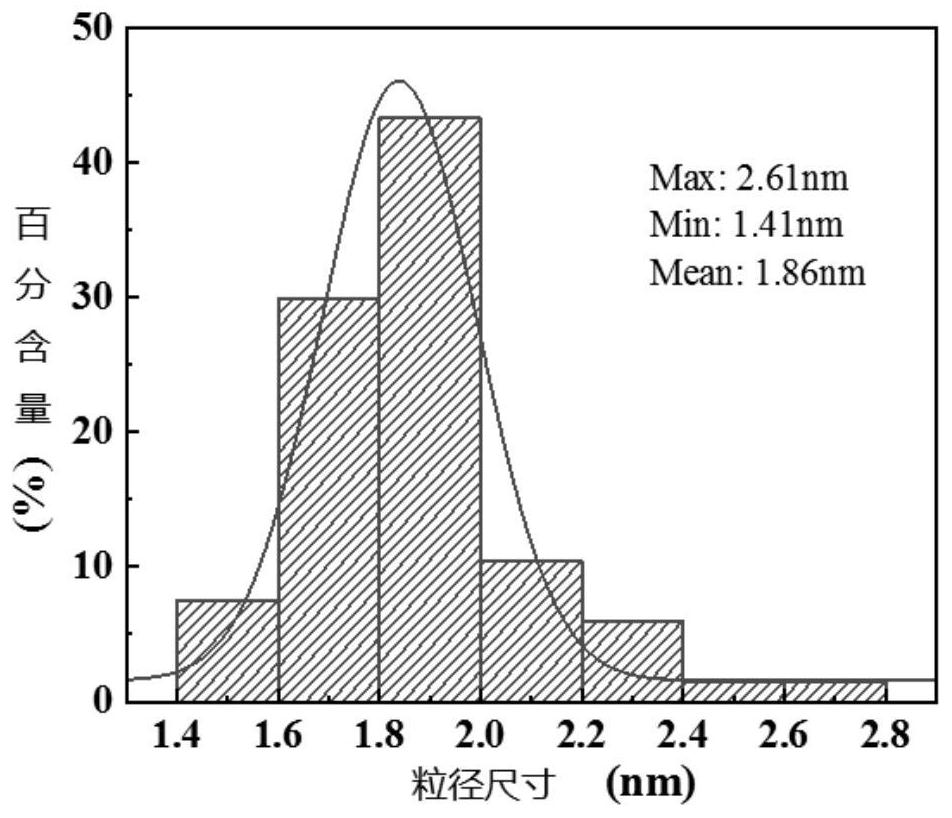

[0025] This example provides a method for preparing ultrafine ruthenium nanocatalysts in situ. Take 0.283g of hydrotalcite and put it into a beaker, add 6mL of deionized water, and add 14mL of 0.01mol / L RuCl dropwise. 3 Solution, ultrasonically disperse for 2min under 400W ultrasonic power, stir and impregnate at room temperature for 12h, centrifuge to collect the precipitate and place it in a 60°C oven to dry for 6h. After pumping air to make the absolute pressure reach 80Pa, apply high voltage, adjust the discharge current to 2.5A, discharge once for 10 minutes, and repeat the discharge 4 times to prepare a hydrotalcite-supported ultrafine ruthenium nanocatalyst with a loading capacity of 5wt.%. It is marked as Ru / HT-P, and the particle size of the ruthenium nanoparticles loaded therein is 1.41-2.62nm.

Embodiment 2

[0027] This embodiment provides a method for in-situ preparation of ultrafine ruthenium nanocatalysts. Put 0.283g of hydrotalcite into a beaker, add 6mL of deionized water, and add 14mL of 0.01mol / L Ru(OAc) dropwise. 3 Solution, ultrasonically disperse for 2min under 400W ultrasonic power, stir and impregnate at room temperature for 12h, centrifuge to collect the precipitate and place it in a 60°C oven to dry for 6h. After pumping air to make the absolute pressure reach 60Pa, apply high voltage, adjust the discharge current to be 2.0A, discharge once for 5 minutes, and discharge repeatedly for 10 times to prepare a hydrotalcite-supported ultrafine ruthenium nanocatalyst with a loading capacity of 5wt.%. The particle diameter of the ruthenium nanoparticles loaded therein is 1.41-2.62nm.

Embodiment 3

[0029] The present embodiment provides a method for in-situ preparation of ultra-fine ruthenium nanocatalysts. Put 0.283g of hydrotalcite into a beaker, add 6mL of deionized water, and add 14mL of 0.01mol / L Ru(NO)(NO) dropwise. 3 ) 3 Solution, ultrasonically disperse for 2min under 400W ultrasonic power, stir and impregnate at room temperature for 12h, centrifuge to collect the precipitate and place it in a 60°C oven to dry for 6h. After degassing, pump air to make the absolute pressure reach 60Pa, apply high voltage, adjust the discharge current to 2.0A, discharge once for 20 minutes, and repeat the discharge 6 times to prepare a hydrotalcite-supported ultrafine ruthenium nanocatalyst with a loading capacity of 5wt.%. Among them, the particle diameter of the ruthenium nanoparticles loaded therein is 1.41-2.62nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com