Cement-based high-temperature-resistant grouting material and preparation method thereof

A high-temperature-resistant, grouting technology, applied in the field of grouting, can solve problems such as insufficient high-temperature resistance, and achieve the effects of enhancing various properties, reducing gaps, and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

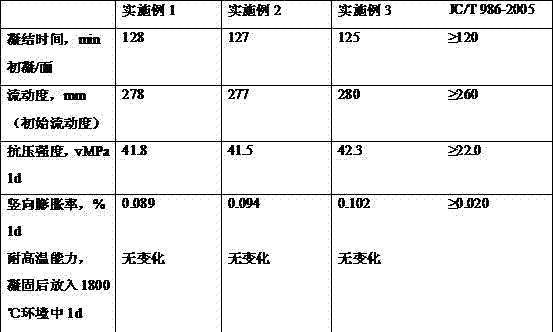

Examples

Embodiment 1

[0025] A cement-based high-temperature-resistant grouting material of this embodiment includes the following raw materials in parts by weight:

[0026] 100 parts of cement, 120 parts of quartz sand, 50 parts of fly ash, 15 parts of silicon powder, 4 parts of titanium boride, 12 parts of carbon fiber, 20 parts of steel fiber, 20 parts of water glass, 5 parts of expansion agent, 1 part of water reducer , 1 part of defoamer, 2 parts of antifreeze, 0.5 part of early strength agent, and 0.5 part of retarder.

[0027] In this embodiment, the cement is ordinary Portland cement, the mesh of fly ash is 200 mesh, and the mesh of silicon powder and titanium boride is 80 mesh.

[0028] In this embodiment, the quartz sand is quartz sand with three different particle sizes of 2 mesh, 15 mesh and 30 mesh, and the weight ratio between the three kinds is 1:2:3.

[0029] In this embodiment, the carbon fiber and the steel fiber both have a diameter length of 0.1 mm and a length of 1 mm.

[003...

Embodiment 2

[0037] A cement-based high-temperature-resistant grouting material of this embodiment includes the following raw materials in parts by weight:

[0038] 100 parts of cement, 125 parts of quartz sand, 55 parts of fly ash, 15.5 parts of silicon powder, 5 parts of titanium boride, 13 parts of carbon fiber, 22 parts of steel fiber, 25 parts of water glass, 7 parts of expansion agent, 2 parts of water reducer , 1.5 parts of defoamer, 3 parts of antifreeze, 1 part of early strength agent, and 0.7 parts of retarder.

[0039] In this embodiment, the cement is ordinary Portland cement, the mesh number of fly ash is 300 mesh, and the mesh number of silicon powder and titanium boride is 80 mesh.

[0040] In this embodiment, the quartz sand is quartz sand with three different particle sizes of 10 mesh, 20 mesh and 40 mesh, and the weight ratio between the three kinds is 1:2:3.

[0041] In this embodiment, the carbon fiber and the steel fiber both have a diameter length of 0.15 mm and a le...

Embodiment 3

[0049] A cement-based high-temperature-resistant grouting material of this embodiment includes the following raw materials in parts by weight:

[0050] 100 parts of cement, 130 parts of quartz sand, 60 parts of fly ash, 16 parts of silicon powder, 7 parts of titanium boride, 14 parts of carbon fiber, 25 parts of steel fiber, 30 parts of water glass, 8 parts of expansion agent, 3 parts of water reducer , 2 parts of defoamer, 5 parts of antifreeze, 1.5 parts of early strength agent, and 0.8 parts of retarder.

[0051] In this embodiment, the cement is ordinary Portland cement, the mesh of fly ash is 300 mesh, and the mesh of silicon powder and titanium boride is 100 mesh.

[0052] In this embodiment, the quartz sand is quartz sand with three different particle sizes of 15 mesh, 30 mesh and 50 mesh, and the weight ratio between the three kinds is 1:2:3.

[0053] In this embodiment, the carbon fiber and the steel fiber both have a diameter length of 0.2 mm and a length of 3 mm.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesh | aaaaa | aaaaa |

| Mesh | aaaaa | aaaaa |

| Mesh | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com