High-performance water-based industrial anticorrosive paint and preparation method thereof

An anti-corrosion coating, high-performance technology, applied in the field of coatings, can solve the problems of serious environmental pollution, high VOC content, slow paint film drying, etc., to achieve the effect of high solid content, low environmental pollution, and good adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] The preparation method of the emulsifier BTCL that the present invention uses is as follows:

[0045] 1. React cardanol and maleic anhydride with a molar ratio of 1:1 at 160-170°C. When the acid value reaches 120-125mgKOH / g, it is the end of the reaction, and the monovalent cardanol maleic anhydride required by the present invention is obtained. acid monoester;

[0046] 2. Put the monobasic acid monoester of cardanol maleic anhydride and polyethylene glycol in a molar ratio of 1:1.1 into the reactor, add 0.2% of the amount of concentrated sulfuric acid as a catalyst for the reaction, and heat it at 200-220°C Reflux esterification for 3 hours, that is, the acid value ≤ 1mgKOH is qualified.

[0047] 3. After the central control is qualified, the temperature is lowered to below 180°C, vacuumized, and the xylene used for reflux is extracted to obtain the emulsifier BTCL of the present invention.

[0048] The specific formula of emulsifier BTCL is as follows:

[0049] The...

Embodiment 1

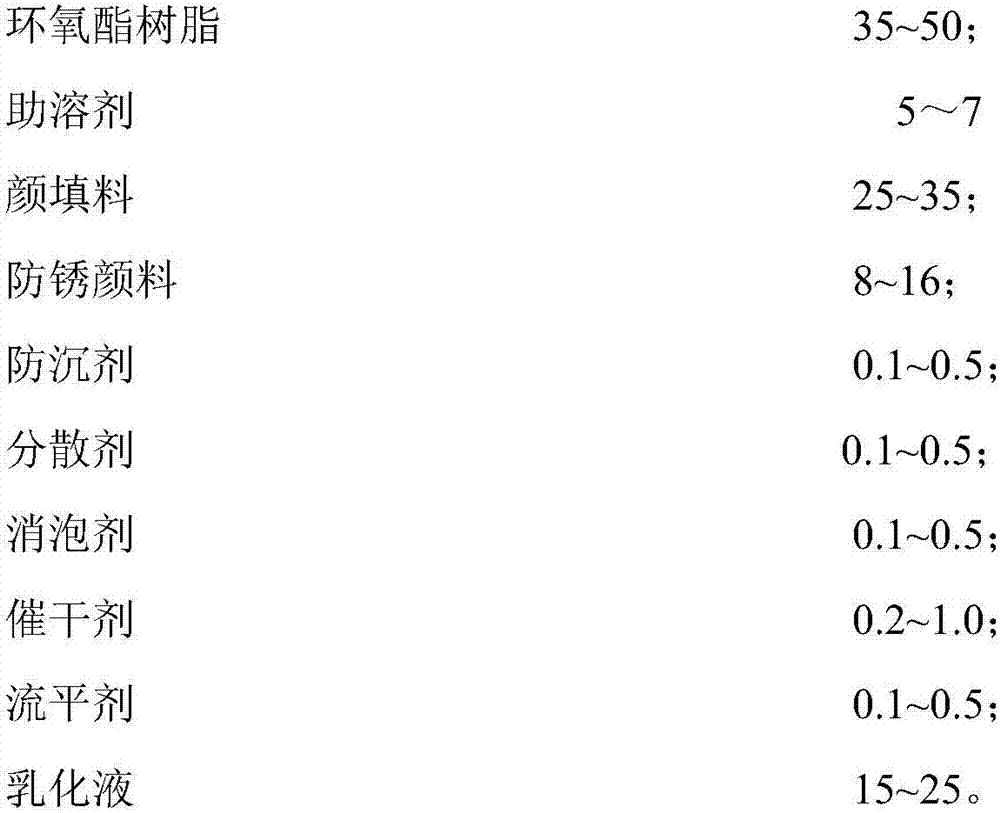

[0054] A kind of high-performance water-based industrial anticorrosion coating, formula is as follows (weight part):

[0055]

[0056]

[0057] Wherein, the mass solid concentration of described epoxy ester resin is 55%, comprises the component of following parts by weight:

[0058]

[0059] Wherein, the mass solid concentration of the buoyant liquid is 2±0.1%, including the following components in parts by weight:

[0060] Emulsifier BTCL 20;

[0061] Deionized water 980;

[0062] The preparation method is as follows:

[0063] (1) Add the solvent of 5-7% of the formula amount under the stirring of epoxy ester resin and stir evenly, then add the anti-sedimentation agent, 1000r / min high-speed dispersion for 10min;

[0064] (2) Then add dispersants, pigments and fillers, and anti-rust pigments, and disperse at a high speed of 1000r / min for 20min to obtain a slurry;

[0065] (3) Grind the slurry until the fineness reaches 50 μm, put it into the paint tank, add drier,...

Embodiment 2

[0074] A kind of high-performance water-based industrial anticorrosion coating, formula is as follows (weight part):

[0075]

[0076] Wherein, the mass solid concentration of described epoxy ester resin is 56%, comprises the component of following parts by weight:

[0077]

[0078]

[0079] Wherein, the mass solid concentration of the buoyant liquid is 2±0.1%, including the following components in parts by weight:

[0080] Emulsifier BTCL 20;

[0081] Deionized water 980.

[0082] The preparation method is as follows:

[0083] (1) Add the solvent of 5-7% of the formulation amount under the stirring of epoxy ester resin and stir evenly, then add the anti-sedimentation agent, and disperse at 800r / min for 15min at high speed;

[0084] (2) Add dispersants, pigments and fillers, anti-rust pigments, and disperse at a high speed of 800r / min for 15min to obtain a slurry;

[0085] (3) Grind the slurry until the fineness reaches 50 μm, put it into the paint tank, add drier...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com