Downhole mining, screening, mixing and filling integrated gangue cement structure filling system and method

A technology of gangue and filling slurry, which is applied to filling materials, mining equipment, earth square drilling and mining, etc., can solve the problems of high cost of filling coal mining, achieve good filling effect, save filling materials, and improve quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

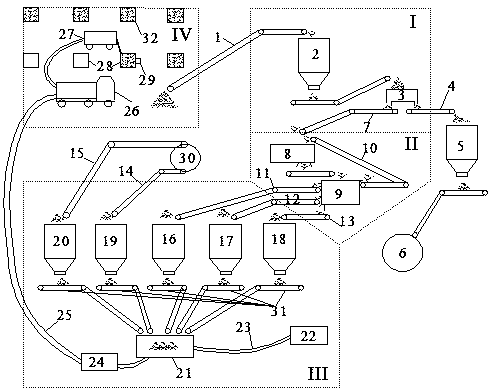

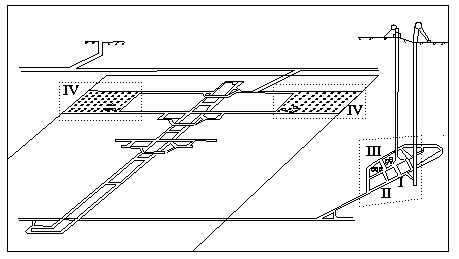

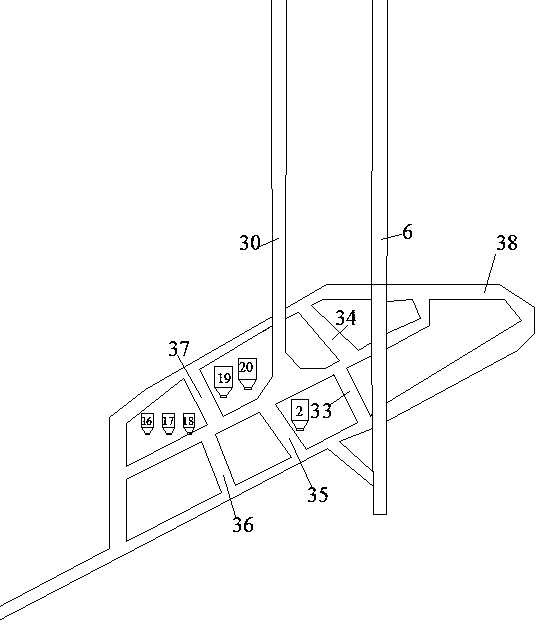

[0036] Such as figure 1 , an underground mining, screening, mixing and filling integrated gangue cement structure filling system, including an underground coal and gangue separation device I, an underground gangue crushing and screening device II, an underground filling material weighing and stirring device III, and an underground filling slurry conveying device And pouring device IV, PLC control device;

[0037] Described underground coal gangue separation device 1 comprises raw coal conveyor belt 1, raw coal bunker 2, raw coal feeding belt, coal gangue separation device 3, clean coal conveyor belt 4, gangue conveyor belt 7; When it arrives at the coal bunker 2 in the mining area, it enters the gangue classification device through the raw coal feeding belt, and the separated clean coal is transported to the wellhead of the main shaft through the clean coal conveying belt 4, and the separated gangue enters the underground gangue through the gangue conveying belt 7 Crushing an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com