Pixel driving unit, forming method thereof, display panel and pixel driving circuit

A driving unit and pixel technology, applied in circuits, electrical components, electrical solid-state devices, etc., can solve problems such as poor uniformity of LTPSTFT devices, affecting display brightness stability, and large differences in driving current, achieving low cost and high integration degree, the effect of reducing the area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The specific embodiments of the pixel driving unit and its forming method, the display backplane, and the pixel driving circuit provided by the present invention will be described in detail below with reference to the accompanying drawings.

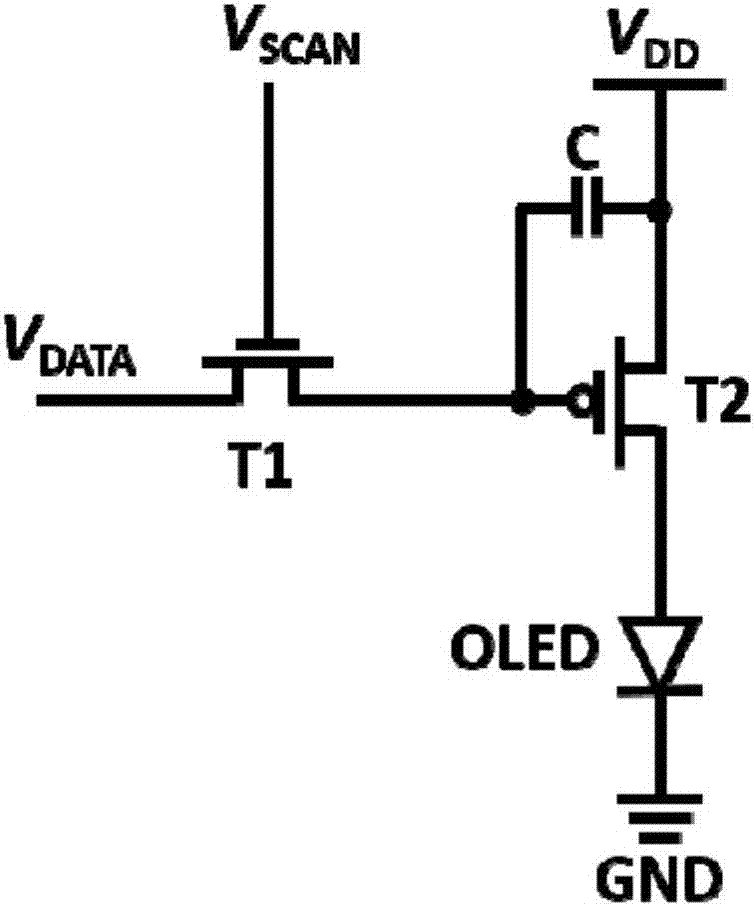

[0039] Please refer to Figure 1A , Is a schematic diagram of an equivalent circuit of a pixel driving circuit according to an embodiment of the present invention.

[0040] The pixel driving circuit includes: a second transistor T2, the second transistor T2 is an organic thin film transistor; a first transistor T1, the first transistor T1 is a low temperature polysilicon thin film transistor or an amorphous oxide thin film transistor, the first transistor T1 The gate of a transistor T1 is connected to the scan signal terminal V SCAN , The drain electrode of the first transistor T1 is connected to the data signal terminal V DATA , The source electrode of the first transistor T1 is connected to the gate of the second transistor T2; the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com