Production method of high-fire-retardant and fire-resistant cable for CRH train

A technology of fire-resistant cables and production methods, which is applied in the direction of insulated cables, cable/conductor manufacturing, cables, etc., can solve problems such as the inability to ensure the continuity of power supply and signal data transmission, meet the requirements of low smoke and halogen-free, and strengthen mechanical resistance Strength, the effect of improving self-strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

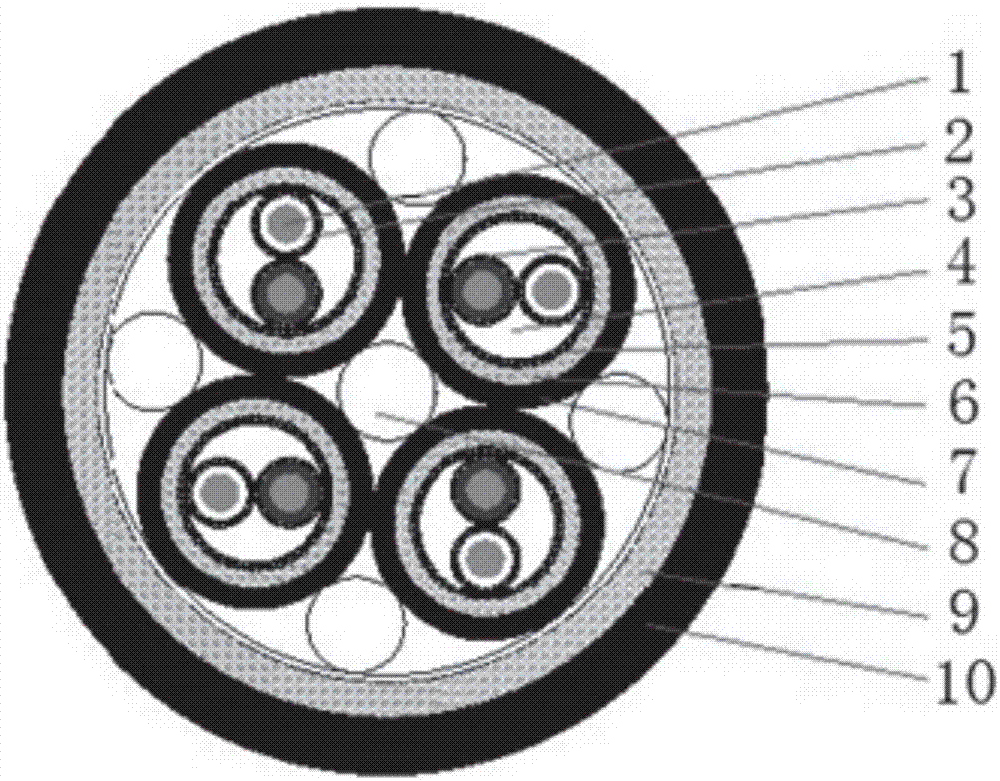

[0050] The insulating layer a or insulating layer b of the present invention is prepared from the following raw materials in parts by weight, wherein: 60% cross-linked polyethylene, 35% polypropylene and 5% organic silicon; the first sheath layer 10, the second sheath Layer 7 is prepared from the following raw materials in parts by weight, wherein: 60% polyethylene base material, 38% polypropylene and 2% calcium hydroxide.

[0051] The main components of the fireproof material 4 of the present invention are mica powder, accounting for 98% by weight; alkaline metal oxides, accounting for 2% by weight, and the alkaline metal oxide is magnesium oxide.

[0052] A production method of a high-flame-resistance fire-resistant cable for an EMU of the present invention comprises the following specific steps:

[0053] (1) Extrusion of insulating layer: According to the diameter of the cable, choose 80mm or 120mm single-screw extruder to extrude, and the extrusion temperature is controlle...

Embodiment 2

[0059] The insulating layer a or insulating layer b of the present invention is prepared from the following raw materials in parts by weight, wherein: 65% cross-linked polyethylene, 30% polypropylene and 5% organic silicon; the first sheath layer 10, the second sheath Layer 7 is prepared from the following raw materials in parts by weight, wherein: 60% polyethylene base material, 35% polypropylene and 5% calcium hydroxide.

[0060] The main components of the fireproof material 4 of the present invention are mica powder, accounting for 95% by weight; alkaline metal oxides, accounting for 5% by weight, and the alkaline metal oxide is alumina.

[0061] A production method of a high-flame-resistance fire-resistant cable for an EMU of the present invention comprises the following specific steps:

[0062] (1) Extrusion of insulating layer: According to the diameter of the cable, choose 80mm or 120mm single-screw extruder to extrude, and the extrusion temperature is controlled at 160...

Embodiment 3

[0068] The insulating layer a or insulating layer b of the present invention is prepared from the following raw materials in parts by weight, wherein: 55% cross-linked polyethylene, 40% polypropylene and 5% organic silicon; the first sheath layer 10, the second sheath Layer 7 is prepared from the following raw materials in parts by weight, wherein: 63% polyethylene base material, 35% polypropylene and 2% calcium hydroxide.

[0069] The main components of the fireproof material 4 of the present invention are mica powder, accounting for 98% by weight; alkaline metal oxides, accounting for 2% by weight, and the alkaline metal oxide is calcium oxide.

[0070] A production method of a high-flame-resistance fire-resistant cable for an EMU of the present invention comprises the following specific steps:

[0071] (1) Extrusion of insulating layer: According to the diameter of the cable, choose 80mm or 120mm single-screw extruder to extrude, and the extrusion temperature is controlled ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com