Arsenic-polluted soil passivator, preparation method and method for controlling arsenic-polluted soil

A passivating agent and arsenic pollution technology, which is applied in the field of remediation and treatment of polluted farmland soil, can solve the problems of complex preparation process, low efficiency, time-consuming and the like, so as to improve soil fertility, reduce the effectiveness of arsenic, and simplify the preparation process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

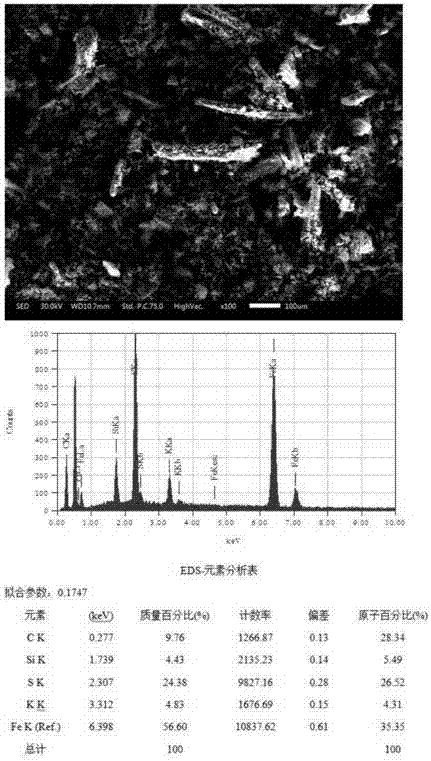

[0029] Raw materials: rice straw 31.13%, FeSO 4 ·7H 2 O 64.89%, 30% H 2 o 2 3.98%

[0030] Preparation:

[0031] After the rice straw is ground, pass it through a 100-mesh sieve and set aside. Take 10g of rice straw powder and place it in 100ml of 0.75mol / L FeSO 4 ·7H 2 soaked in O solution, to FeSO 4 ·7H 2 Add 30% H to the O solution 2 o 2 , slowly added at a rate of 0.4ml / min to keep n(FeSO 4 ·7H 2 O):n(H 2 o 2 )=1:0.5.

[0032]Put the mixed solution under a magnetic stirrer, stir at 30°C for 24h, filter and dry it, put it in a muffle furnace at 300°C at a heating rate of 17°C / min for carbonization for 2h, and take it out after cooling to obtain passivation agent.

Embodiment 2

[0034] Raw materials: rice straw 40.09%, FeSO 4 ·7H 2 O 58.09%, 30% H 2 o 2 1.82%

[0035] Preparation:

[0036] After the rice straw is ground, it is passed through an 80-mesh sieve, and is set aside. Take 10g of rice straw powder and place it in 100ml of 0.36mol / L FeSO 4 ·7H 2 soaked in O solution, to FeSO 4 ·7H 2 Add 30% H to the O solution 2 o 2 , slowly added at a rate of 0.4ml / min to keep n(FeSO 4 ·7H 2 O):n(H 2 o 2 )=1:0.3.

[0037] Put the mixed solution under a magnetic stirrer, stir at 28°C for 24 hours, filter and dry it, and then carbonize it in a muffle furnace at 350°C at a heating rate of 15°C / min for 2.5 hours, and take it out after cooling to obtain passivation agent.

Embodiment 3

[0039] Raw materials: rice straw 20.00%, FeSO 4 ·7H 2 O 76.26%, 30% H 2 o 2 3.74%

[0040] Preparation:

[0041] After the rice straw is ground, pass it through a 200-mesh sieve and set aside. Take 10g of rice straw powder and place it in 100ml of 1.38mol / L FeSO 4 ·7H 2 soaked in O solution, to FeSO 4 ·7H 2 Add 30% H to the O solution 2 o 2 , slowly added at a rate of 0.4ml / min to keep n(FeSO 4 ·7H 2 O):n(H 2 o 2 )=1:0.4.

[0042] Put the mixed solution under a magnetic stirrer, stir at 25°C for 24h, filter and dry it, put it in a muffle furnace at 400°C at a heating rate of 20°C / min for carbonization for 3h, and take it out after cooling to obtain the passivation agent .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com