Method for resource utilization of abandoned crop straws

A technology for recycling crop stalks, which is applied in the field of agricultural waste resource utilization, can solve problems such as damage to the farmland soil environment, waste of biological resources, and atmospheric environmental pollution, and achieve the effects of improving insect-proof performance, prolonging service life, and improving plasticity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

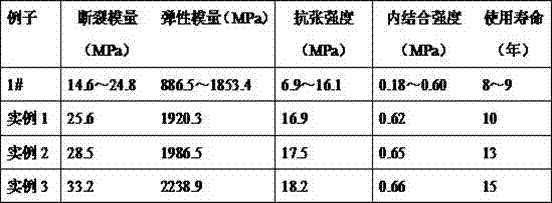

Examples

example 1

[0025]Weigh 3 kg of sweet potato vines, wash them twice with clean water, spread the washed sweet potato vines evenly in the sun and expose them to the sun until the moisture content of the discarded crop stalks is 15%, collect the exposed sweet potato vines, and cut them into lengths of 3cm short stalks, and put the obtained short stalks into 8L of 3% sodium hydroxide solution with a mass fraction of 3%, at a speed of 300r / min, stir and mix for 2h, and filter to obtain an alkali leaching filter residue; pour the obtained alkali leaching filter residue into a container In the reactor with 6L of water, seal the reactor again, and turn on the heater of the reactor at a speed of 300r / min until the pressure inside the reactor reaches 1.6MPa. Valve, so that the material in the reaction kettle is injected into the receiving kettle; the bottom of the receiving kettle and the reaction kettle are connected by a pipeline except the valve; the material in the receiving kettle is naturally...

example 2

[0027] Weigh 4kg of corn stalks, wash them repeatedly with clean water for 3 times, spread the washed corn stalks evenly in the sun and expose them to the sun until the moisture content of the corn stalks is 18%, collect the exposed corn stalks, and cut them into 4cm lengths with a guillotine Short stalks, and put the obtained short stalks into 9L of 4% sodium hydroxide solution by mass fraction, stir and mix for 3 hours under the condition of rotating speed of 400r / min, filter to obtain alkali leaching filter residue; pour the obtained alkali leaching filter residue into a container 7L of water in the reactor, then seal the reactor, and turn on the reactor heater at a speed of 400r / min until the pressure in the reactor reaches 1.8MPa, and after the pressure-holding reaction for 45s, open the discharge valve at the bottom of the reactor , so that the material in the reactor is sprayed into the receiving tank; the receiving tank and the bottom of the reactor are connected throug...

example 3

[0029] Weigh 5kg of wheat straw, wash it repeatedly with water for 4 times, spread the washed wheat straw evenly in the sun and expose it to the sun until the moisture content of the wheat straw is 20%, collect the exposed wheat straw, and cut it into a length of 5cm with a guillotine short stalks, and put the obtained short stalks into 10L of 5% sodium hydroxide solution by mass fraction, stir and mix for 4 hours under the condition of rotating speed of 500r / min, and filter to obtain the alkali leaching filter residue; pour the obtained alkali leaching filter residue into a container 8L of water in the reactor, then seal the reactor, and turn on the heater of the reactor at a speed of 500r / min until the pressure inside the reactor reaches 2.0MPa. , so that the material in the reactor is sprayed into the receiving tank; the receiving tank and the bottom of the reactor are connected through a pipeline except the valve; the material in the receiving tank is naturally cooled to ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com