High-stability resistive random access memory based on graphene oxide

A resistive memory, high-stability technology, applied in nanotechnology for information processing, nanotechnology for materials and surface science, electrical components, etc., to reduce electrical power consumption, improve work stability, and optimize performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Example 1 A highly stable resistive memory based on graphene oxide

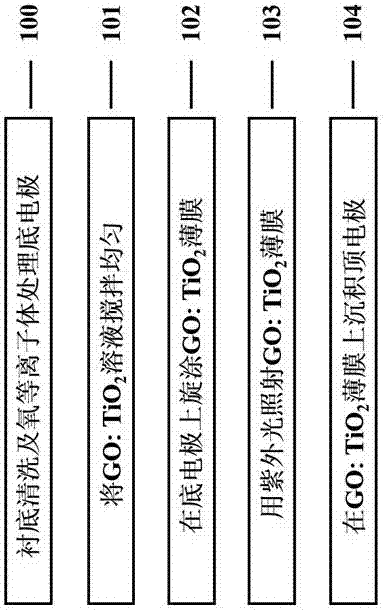

[0027] See figure 1 , 2 , 3, 4, a high-stability resistive variable memory based on graphene oxide, the specific manufacturing process is as follows:

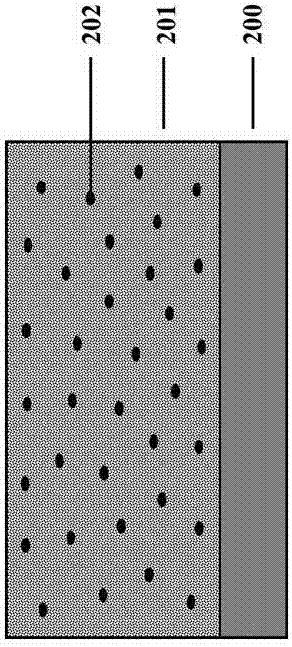

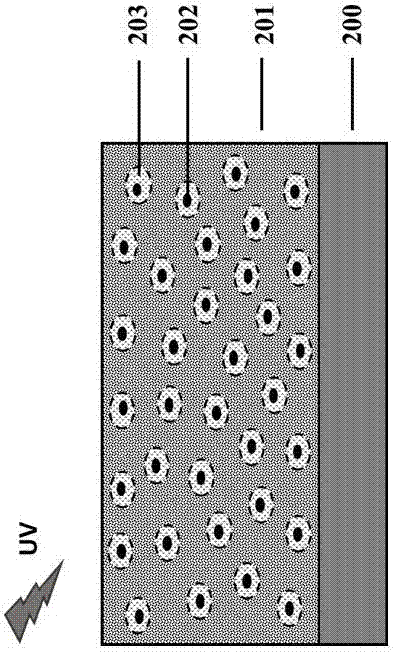

[0028] Step 100: if figure 2 As shown, the conductive glass 200 substrate was ultrasonically cleaned with acetone, ethanol, and deionized water for 10 minutes in sequence, dried with nitrogen, and then the surface of the ITO conductive glass 200 was treated with oxygen plasma.

[0029] Step 101: Doping 1 mg of anatase phase TiO2 nanoparticles 203 with a particle size of 10 nm into 10 ml of graphene oxide in ethanol solution, TiO in the solution 2 The mass ratio of nanoparticles 203 to graphene oxide is 1:10, and the mixed solution is placed on a magnetic stirrer and fully stirred for 10 hours;

[0030] Step 102: Spin-coat the graphene oxide mixed solution in step 101 onto the ITO conductive glass 200 at a low speed of 500r / min for 20s and a high sp...

Embodiment 2

[0033] Example 2 A highly stable resistive memory based on graphene oxide

[0034] See figure 1 , 2 , 3, 4, a high-stability resistive variable memory based on graphene oxide, the specific manufacturing process is as follows:

[0035] Step 100: if figure 2 As shown, the conductive glass 200 substrate was ultrasonically cleaned with acetone, ethanol, and deionized water for 15 minutes in sequence, dried with nitrogen, and then the surface of the FTO conductive glass 200 was treated with oxygen plasma.

[0036]Step 101: 0.5 mg of anatase phase TiO with a particle size of 20 nm 2 Nanoparticles 203 are doped into the ethanol solution of 10ml graphene oxide, and TiO in the solution 2 The mass ratio of nanoparticles 203 to graphene oxide is 1:30, and the mixed solution is placed on a magnetic stirrer and fully stirred for 8 hours;

[0037] Step 102: Spin-coat the graphene oxide mixed solution in step 101 onto the FTO conductive glass 200, spin-coat at a low speed of 500r / min f...

Embodiment 3

[0040] Example 3 A highly stable resistive memory based on graphene oxide

[0041] See figure 1 , 2 , 3, 4, a high-stability resistive variable memory based on graphene oxide, the specific manufacturing process is as follows:

[0042] Step 100: if figure 2 As shown, the conductive glass 200 substrate was ultrasonically cleaned with acetone, ethanol, and deionized water for 8 minutes in sequence, dried with nitrogen, and then the surface of the ITO conductive glass 200 was treated with oxygen plasma.

[0043] Step 101: Doping 1mg of anatase phase TiO2 nanoparticles 203 with a particle size of 15nm into 10ml of graphene oxide ethanol solution, the mass ratio of TiO2 nanoparticles 203 to graphene oxide in the solution is 1:20, mixing The solution was fully stirred on a magnetic stirrer for 10 hours;

[0044] Step 102: Spin-coat the graphene oxide mixed solution in step 101 onto the ITO conductive glass 200 at a low speed of 500r / min for 20s and a high speed of 2000r / min for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com