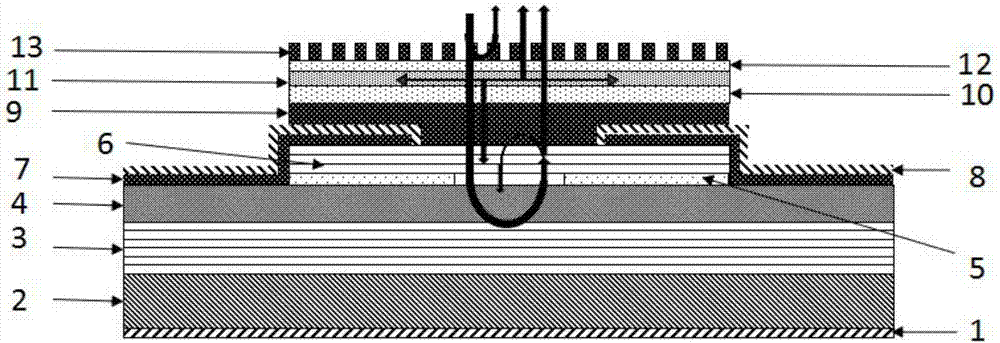

Guided mode resonance grating narrow line width vertical-cavity surface emitting laser (VESEL) and preparation method thereof

A technology of vertical cavity surface emission and guided mode resonance, which is applied in the direction of semiconductor lasers, lasers, laser components, etc., can solve the problem that the light source cannot meet the needs of big data information systems, and achieve simple structure, narrow laser line width, and small volume Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The narrow linewidth vertical cavity surface emitting laser designed by the present invention can be combined with figure 2 -- Figure 9 , introduces its preparation method in detail:

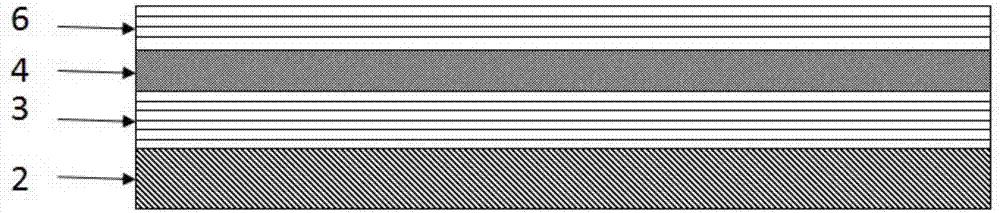

[0025] Step 1: If figure 2 As shown, the metal organic chemical vapor deposition (MOCVD) was used to alternately grow n-Al on the n-type GaAs substrate 0.1 Ga 0.9 As layer and n-Al 0.9 Ga 0.1 A total of 36 pairs of As layers constitute the lower DBR; then grow Al 0.2 Ga 0.8 As / Al 0.12 In 0.18 Ga 0.7 As quantum well structure constitutes the active region; re-growth Al 0.98 Ga 0.02 As oxidizes the current confinement layer; then grows a few pairs of Al 0.9 Ga 0.1 As / Al 0.1 Ga 0.9 DBR on As; final growth doping concentration is 1x10 19 / cm -3 P-type Al 0.1 Ga 0.9 As, it is convenient to form a good ohmic contact with the injection electrode;

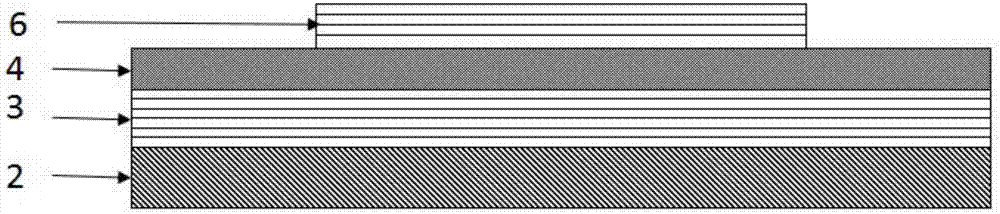

[0026] Step 2: If image 3 As shown, a cylindrical step with a diameter of 60 μm was etched using a combination of photolitho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com