Processing method of dried radish food

A food processing and radish drying technology, which is applied in food science, climate change adaptation, etc., can solve the problems of radish odor retention, unfavorable removal of radish eggs, poor processing safety, etc., to ensure food safety and eliminate residual pesticides , the effect of preventing oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

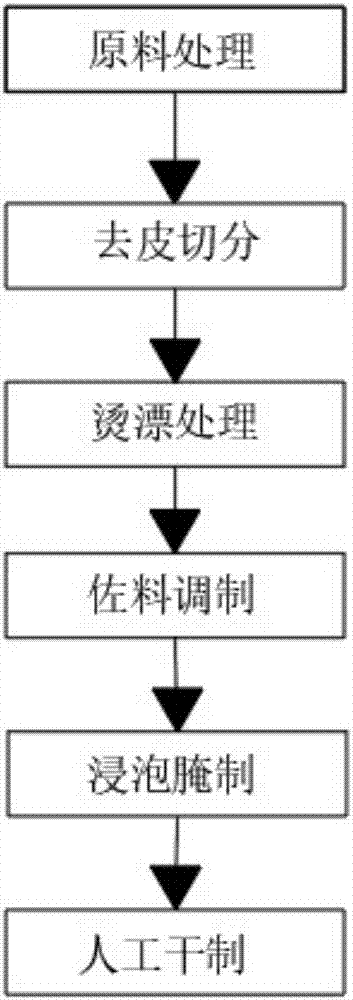

[0020] A method for processing dried radish food, comprising the steps of:

[0021] 1) Raw material treatment: soak the raw material in light salt water, the concentration of light salt water is 1.0%, and the soaking time is 10.0 minutes. After the attachment on the surface is soft, wash it with clean water;

[0022] 2) Peeling and cutting: the radish is peeled by the radish peeling machine. After the peeling is completed, the radish is cut into slices, and the thickness of the radish slice is 2.0mm;

[0023] 3) Blanching treatment: put the radish slices in steam for 2.0 minutes, and soak them in cold water immediately after blanching;

[0024] 4) Seasoning preparation: it includes the following components in parts by weight: 2.0 parts of white sugar, 10.0 parts of soy sauce, 4.0 parts of salt, 3.0 parts of sesame oil, 2.0 parts of baking soda, and 100.0 parts of water, which are mixed and stirred for 20.0 minute;

[0025] 5) Soaking and marinating: put the blanched radish s...

Embodiment 2

[0029] A method for processing dried radish food, comprising the steps of:

[0030] 1) Raw material treatment: soak the raw material in light salt water, the concentration of light salt water is 1.5%, and the soaking time is 12.0 minutes. After the attachment on the surface is soft, wash it with clean water;

[0031] 2) Peeling and cutting: the radish is peeled by the radish peeling machine, after the peeling is completed, the radish is cut into slices, and the thickness of the radish slice is 3.0;

[0032] 3) Blanching treatment: put the radish slices in steam for 4.0 minutes, and soak them in cold water immediately after blanching;

[0033] 4) Seasoning preparation: it includes the following components in parts by weight: 3.0 parts of white sugar, 12.0 parts of light soy sauce, 5.0 parts of table salt, 4.0 parts of sesame oil, 2.5 parts of baking soda, and 120.0 parts of water, which are mixed and stirred for 22.0 minute;

[0034] 5) Soaking and marinating: put the blanche...

Embodiment 3

[0038] A method for processing dried radish food, comprising the steps of:

[0039] 1) Raw material treatment: soak the raw material in light salt water, the concentration of light salt water is 2.0%, and the soaking time is 14.0 minutes. After the attachment on the surface is soft, wash it with clean water;

[0040] 2) Peeling and cutting: the radish is peeled by the radish peeling machine. After the peeling is completed, the radish is cut into slices, and the thickness of the radish slice is 4.0mm;

[0041] 3) Blanching treatment: put the radish slices in steam for 5.0 minutes, and soak them in cold water immediately after blanching;

[0042] 4) Seasoning preparation: it includes the following components in parts by weight: 4.0 parts of white sugar, 14.0 parts of light soy sauce, 6.0 parts of table salt, 5.0 parts of sesame oil, 3.0 parts of baking soda, and 140.0 parts of water, which are mixed and stirred for 24.0 minutes ;

[0043] 5) Soaking and marinating: put the bla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com