Preparation method of hierarchical drug-loaded cornea repairing material

A technology of loading drugs and repairing materials, applied in the field of biomedicine, can solve the problems of difficult repair, long time and slow metabolic process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

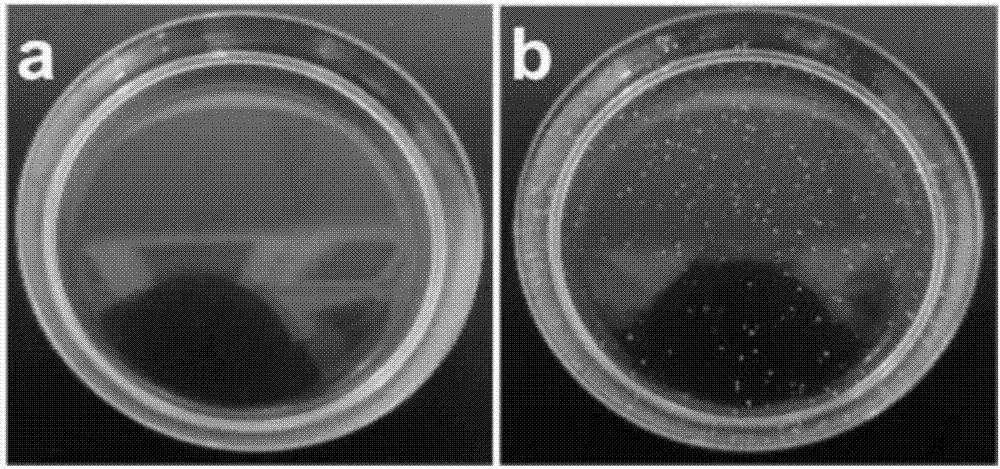

[0022] Weigh 0.8g of gelatin, add it to 80g of hydrochloric acid solution (1wt%), stir mechanically for 4h, stirring speed is 800r / min, fully dissolve to obtain 1wt% (weight ratio) gelatin solution; inject 2mL of gelatin solution into the mold and spread it flat At the bottom, a gelatin film was obtained after vacuum drying for 2 hours at an ambient temperature of 35°C. Add vancomycin to deionized water to prepare a drug solution with a concentration of 1mg / mL, add 0.5mL of the drug solution dropwise on the surface of the dried gelatin film and spread it evenly, place it at a temperature of 35°C, and dry it in vacuum for 1h After the drug completely infiltrates the film and dries, add the gelatin solution and the drug solution in an alternate cycle and repeat the above steps. Finally, a layered drug-loaded corneal repair material with a thickness of 200 μm was obtained. With the same preparation process and conditions, corneal repair materials that are dried naturally at room...

Embodiment 2

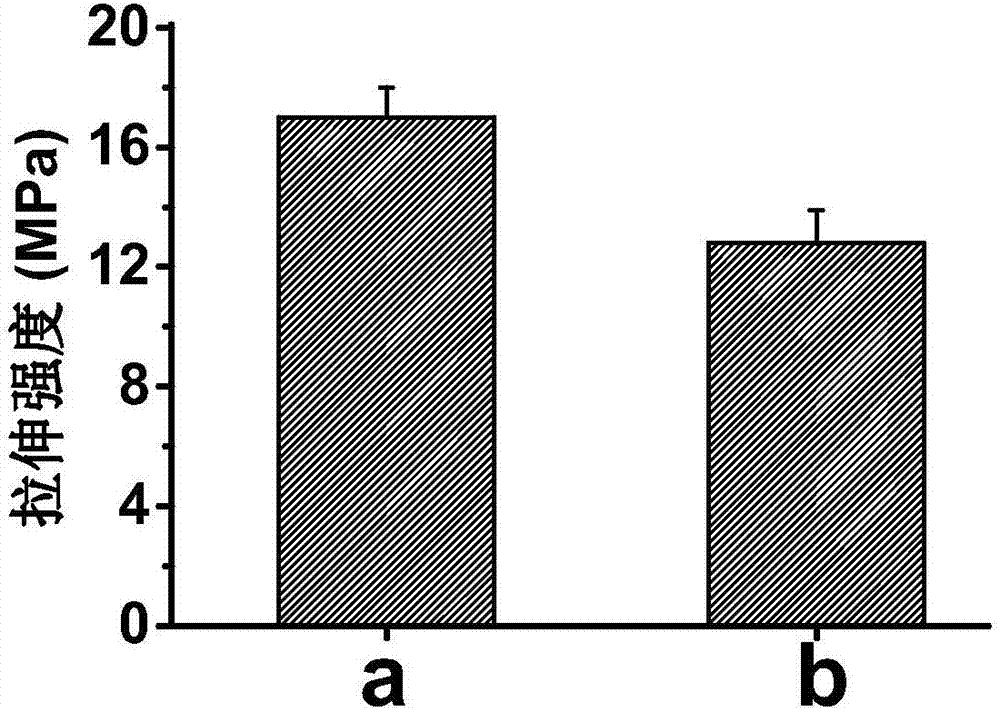

[0024] Weigh 0.6g of collagen, add it to 60g of weak acetic acid solution (1.5wt%), mechanically stir for 48h, stirring speed is 100r / min; inject 2mL of collagen solution into the mold and spread it on the bottom, at an ambient temperature of 37°C The collagen film was prepared after vacuum drying for 6 h. Add tobramycin to deionized water to prepare a drug solution with a concentration of 1mg / mL, add 0.5mL of the drug solution dropwise on the surface of the dried gelatin film and spread it evenly, place it at a temperature of 37°C, and dry it in vacuum 4 hours after the drug completely infiltrates the film and dries, add the collagen solution and the drug solution alternately and repeatedly, and repeat the above steps. Finally, a layered drug-loaded corneal repair material with a thickness of 400 μm was obtained. Under the same preparation conditions and the amount of raw materials, due to the interaction between tobramycin drug and collagen molecular chains, the mechanical ...

Embodiment 3

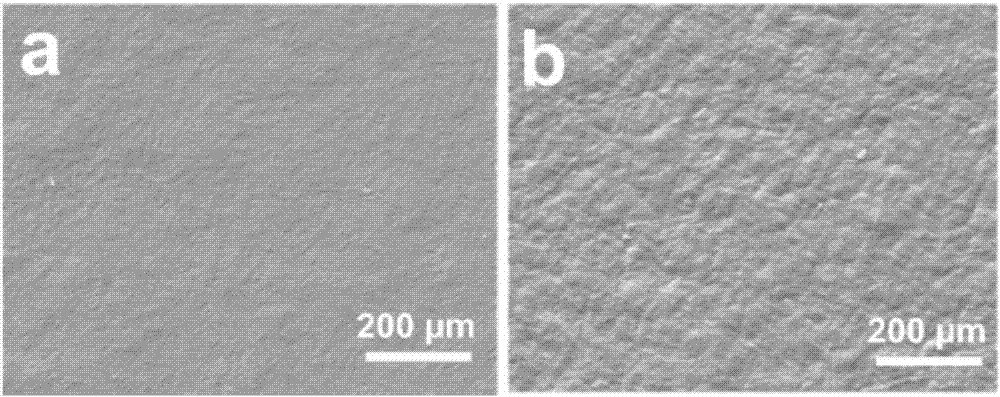

[0026] Take by weighing 0.9g chitosan, join in 30g concentration and be 1wt% hydrochloric acid solution, mechanically stir 4h, stirring speed 800r / min, fully dissolve and make 30wt% (weight ratio) chitosan solution; Inject 1.5mL collagen solution In the mold, the chitosan film was obtained after vacuum drying for 5 hours at an ambient temperature of 35°C. Add ceftriaxone to deionized water to prepare a drug solution with a concentration of 1mg / ml, drop 0.45ml of the drug solution on the surface of the dried chitosan film and spread it evenly, place it at a temperature of 35°C, and vacuum After drying for 3 hours, after the drug was completely infiltrated into the film and dried, the chitosan solution and the drug solution were repeatedly added alternately, and the above steps were repeated; finally, a layered drug-loaded corneal repair material with a thickness of 300 μm was obtained. When the temperature is too high, some drugs are easily inactivated. In the normal temperatur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com