Ultraviolet-curing hyperbranched polyester polyurethane acrylate resin and preparation method thereof

A technology of urethane acrylate and hyperbranched polyester, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problems of inability to perform UV curing and do not contain photocurable groups, and achieve excellent solubility and simple raw materials. Ease of availability and reduced dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

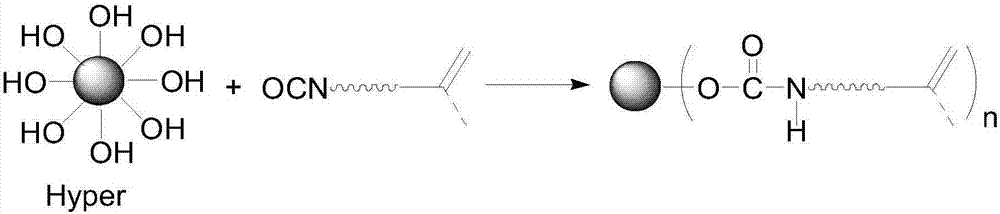

[0025] (1) At room temperature, add 1.2mol isophorone diisocyanate (IPDI), 0.05wt% dibutyltin dilaurate, 0.2wt% 2,6-di-tert-butyl-p-cresol into a dry reaction flask, Add 1.2 mol polycaprolactone acrylate (CA) dropwise under stirring for 1 hour. After the addition, the temperature is raised to 35°C, and the reaction is until the measured -NCO value reaches half of the initial reaction time. Semi-blocked isocyanate IPDI-CA monomer, the synthesis route is as follows figure 1 Shown

[0026] (2) In the reaction flask of step (1), add 0.05wt% dibutyltin dilaurate, 0.2wt% 2,6-di-tert-butyl-p-cresol, and add each hyperbranched molecule dropwise while stirring A mixture of hydroxyl-terminated hyperbranched polyester with a hydroxyl number of 8 and tetrahydrofuran (the amount of tetrahydrofuran is based on the total dissolved hyperbranched polyester), the dripping time is 1 hour, and the heat preservation reaction is completed for 1 hour; then the temperature is slowly raised to 40 ~50℃, ...

Embodiment 2

[0028] (1) At room temperature, add 1.1mol hexamethylene diisocyanate (HDI), 0.05wt% dibutyltin dilaurate, 0.2wt% 2,6-di-tert-butyl-p-cresol into a dry reaction flask, Add 1.0 mol polycaprolactone acrylate (CA) dropwise under stirring for 0.5 hours. After the dropwise addition, the temperature is raised to 45°C, and the reaction is completed until the measured -NCO value reaches half of the initial reaction time. Semi-blocked isocyanate HDI-CA monomer;

[0029] (2) In the reaction flask of step (1), add dropwise a mixture of hydroxyl-terminated hyperbranched polyester with 8 hydroxyl groups on each hyperbranched molecule and tetrahydrofuran under stirring. The dropping time is 1 hour. After holding the reaction for 2 hours; then slowly raising the temperature to 50-60°C and stirring the reaction for 2 hours; then raising the temperature to 70-80°C, stirring the reaction until the measured -NCO value reaches the theoretical value; after removing the solvent tetrahydrofuran under r...

Embodiment 3

[0031] (1) At room temperature, add 1.5mol isophorone diisocyanate (IPDI), 0.05wt% dibutyltin dilaurate, 0.2wt% 2,6-di-tert-butyl-p-cresol into a dry reaction flask, Under stirring, add 1.5 mol of hydroxyethyl acrylate (HEA) dropwise for 1.5 hours. After the addition, the temperature is raised to 40°C, and the reaction is completed until the measured -NCO value reaches half of the initial reaction time, and a semi-sealed is obtained. Terminated isocyanate IPDI-HEA monomer;

[0032] (2) In the reaction flask of step (1), add dropwise a mixture of hydroxyl-terminated hyperbranched polyester with 8 hydroxyl groups on each hyperbranched molecule and tetrahydrofuran under stirring. The dripping time is 2 hours. After completion of the insulation reaction for 4 hours; then slowly increase the temperature to 60-70°C and stir the reaction for 4 hours; then increase the temperature to 80-90°C and stir the reaction until the measured -NCO value reaches the theoretical value; after removing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com