Modified spray-coating flame-retardant type hard foam polyurethane material and preparation method thereof

A rigid polyurethane foam and flame-retardant technology, which is applied in the field of modified spraying flame-retardant rigid polyurethane foam and its preparation, can solve the problem of losing the integration of heat preservation and waterproofing of RPUF materials, the liquid material of component B is perishable, and rigid polyurethane foam To solve the problems such as the deterioration of the hard foam function of the material, to achieve excellent physical and mechanical properties, improve yellowing resistance, and improve flame retardant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

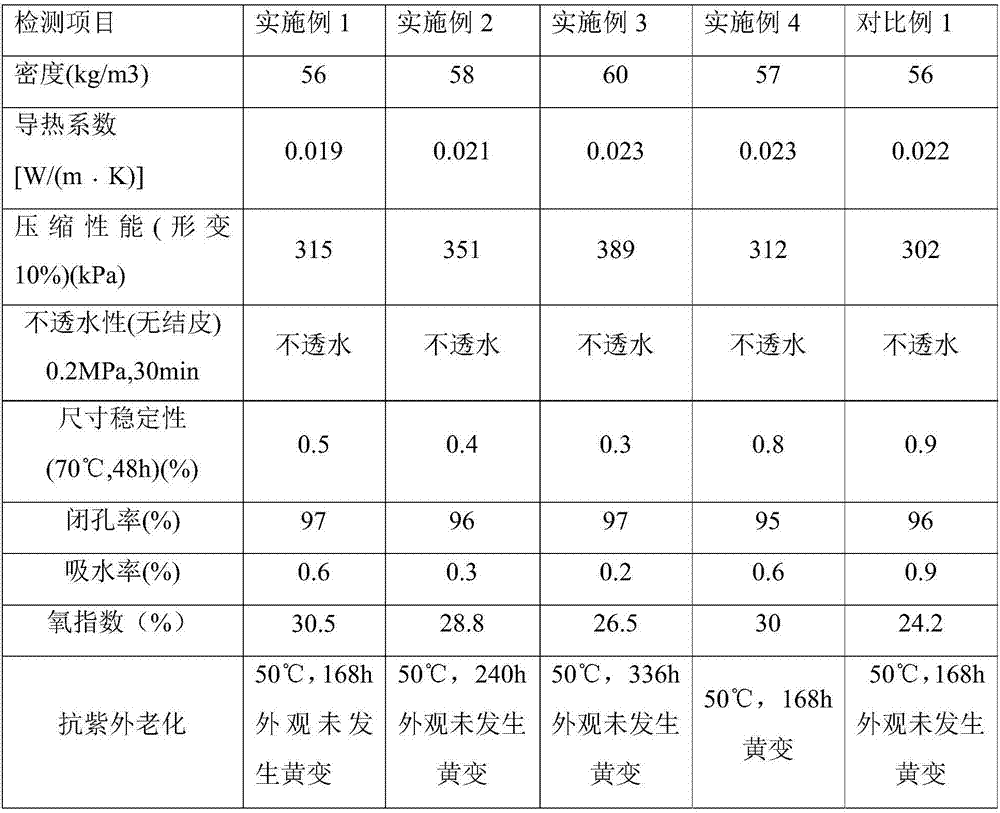

Examples

preparation example Construction

[0036] Another aspect of the present invention provides a kind of preparation method of described modified spraying flame retardant rigid foam polyurethane material, the method comprises:

[0037] (1) The preparation of A component, first dehydrating the liquid flame retardant, then adding polyisocyanate for contact reaction, and finally degassing to obtain the A component;

[0038] (2) Preparation of component B, mixing polyether polyol, flame retardant silicone oil, environmentally friendly foaming agent, composite catalyst, flame retardant and C3-C6 trihydric alcohol mixture, and degassing to obtain component B;

[0039] (3) The A component and the B component are mixed for a foaming reaction, and matured to obtain the modified spray-coated flame-retardant rigid foam polyurethane material.

[0040]According to the present invention, preferably, the reaction conditions of the step (1) include: the dehydration conditions are dehydration at a speed of 800 to 1000r / min, a tempe...

Embodiment 1

[0050] (1) Preparation of component A: According to the designed formula ratio, add liquid flame retardant into a four-necked flask, dehydrate for 3 hours under vacuum conditions with a rotation speed of 800r / min, a temperature of 110°C, and -0.095MPa, and cool down to 55°C , and reduce the rotation speed to 400r / min, and turn off the vacuum, then add polyisocyanate, raise the temperature to 78°C, react for 2h, then cool down to 45°C, and debubble for 20min under the vacuum condition of -0.095MPa to obtain the modified polyisocyanate as A component.

[0051] The design formula of A component is shown in Table 1A.

[0052] Table 1A

[0053] Raw material composition

[0054] (2) Preparation of component B: According to the design formula ratio, in a four-necked flask, add polyether polyol, flame retardant silicone oil, foaming agent, composite catalyst, flame retardant, C3-C6 trihydric alcohol mixture, pass Stir with a booster electric mixer for 40 minutes at a speed...

Embodiment 2

[0060] The preparation method of this embodiment is the same as that of Example 1. The composition and dosage of each component in this embodiment are: the design formula of component A is shown in Table 2A, and the design formula of component B is shown in Table 2B, wherein the composite catalyst It is a mixture of trimethylhydroxyethylpropylenediamine and butyltin diacetate, the weight percentages are 65% and 35% respectively, and the C3-C6 trihydric alcohol mixture is glycerol, 1,2,6 hexanetriol and triol Mixtures of methylolpropane, 50%, 30% and 20% by weight of glycerol, 1,2,6 hexanetriol and trimethylolpropane, respectively, based on the total weight of the C3-C6 triol mixture , the flame retardant is TCPP; the mass ratio of A component to B component is 1.5:1.

[0061] Table 2A

[0062] Raw material composition

model

% by weight / %

liquid flame retardant

Doher-605

35.43

polyisocyanate

CORONATE HXR-90B

64.57

Total

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com