High-carbon ferrochrome smelting method and product

A high-carbon ferrochromium and smelting method technology, applied in the field of metallurgical industry, can solve the problems of high labor intensity of workers, many production links, difficult to collect, etc., and achieve low labor intensity, improved quality and performance, and excellent quality and performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

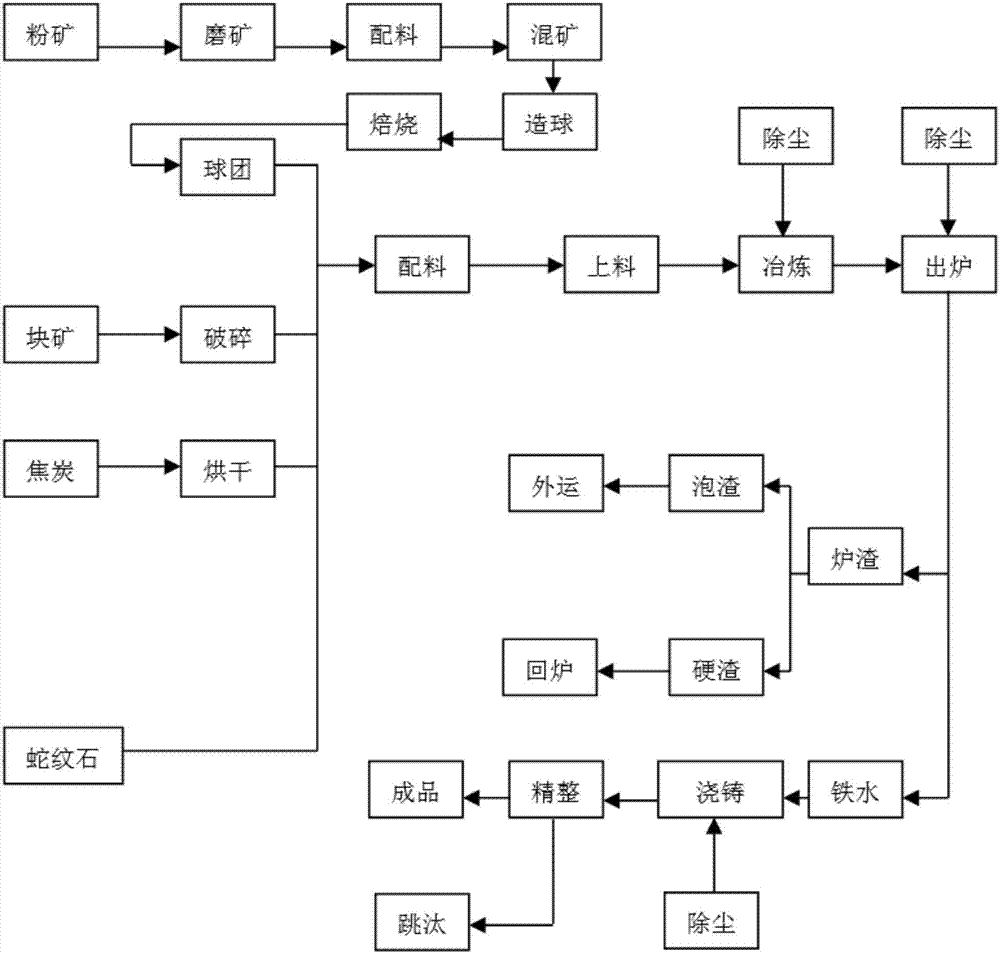

[0095] A method for smelting high-carbon ferrochrome, comprising:

[0096] Prepare materials according to the mass ratio of chromite, coke and stevensite at a ratio of 30:5:1, and the total weight of chromite, coke and stevensite is 20t;

[0097] The fine ore in chromite ore undergoes the pretreatment process of grinding, batching, ore blending, pelletizing, roasting and pelletizing in sequence, wherein the roasting temperature is 1000°C; the lump ore in chromite ore is crushed and pretreated; coke is processed by drying pretreatment;

[0098] The pretreated chromite, coke and stevensite are mixed in proportion and fed into the electric furnace for smelting. The smelting temperature is 1500°C and the smelting time is 5 hours;

[0099] After the smelting is completed, the obtained slag is collected by the transition bag and flows into the water. The volume ratio of water and slag is 2:1; after the smelting is completed, the obtained hard slag is returned to the furnace as a ra...

Embodiment 2

[0103] A method for smelting high-carbon ferrochrome, comprising:

[0104]The mass ratio of chromite, coke and stevensite is 70:15:10 and the total weight of chromite, coke and stevensite is 25t;

[0105] The fine ore in chromite ore undergoes the pretreatment process of grinding, batching, ore blending, pelletizing, roasting and pelletizing in sequence, wherein the roasting temperature is 1300°C; the lump ore in chromite ore is crushed and pretreated; coke is processed by drying pretreatment;

[0106] The pretreated chromite, coke and stevensite are mixed in proportion and fed into the electric furnace for smelting. The smelting temperature is 1650°C and the smelting time is 6 hours;

[0107] After the smelting is completed, the obtained slag is collected by the transition bag and flows into the water. The volume ratio of water and slag is 10:1; after the smelting is completed, the obtained hard slag is returned to the furnace for re-smelting; Below 5mm;

[0108] After the...

Embodiment 3

[0111] A method for smelting high-carbon ferrochrome, comprising:

[0112] The mass ratio of chromite, coke and stevensite is 40:8:3 and the total weight of chromite, coke and serpentine is 30t;

[0113] The fine ore in chromite ore undergoes the pretreatment process of grinding, batching, ore blending, pelletizing, roasting and pelletizing in sequence, in which the roasting temperature is 1200°C; the lump ore in chromite ore is crushed and pretreated; coke is processed by drying pretreatment;

[0114] The pretreated chromite, coke and stevensite are mixed in proportion and fed into the electric furnace for smelting. The smelting temperature is 1800°C and the smelting time is 8 hours;

[0115] After the smelting is completed, the obtained slag is collected by the transition bag and flows into the water. The volume ratio of water and slag is 4:1; after the smelting is completed, the obtained hard slag is returned to the furnace for re-smelting; Below 5mm;

[0116] After the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com