Preparation process of high-purity oxygen-free copper tube target material for sputtering

An oxygen-free copper tube and preparation process technology, which is applied in metal material coating process, sputtering plating, ion implantation plating, etc., can solve the problems of long procurement cycle, complicated process and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

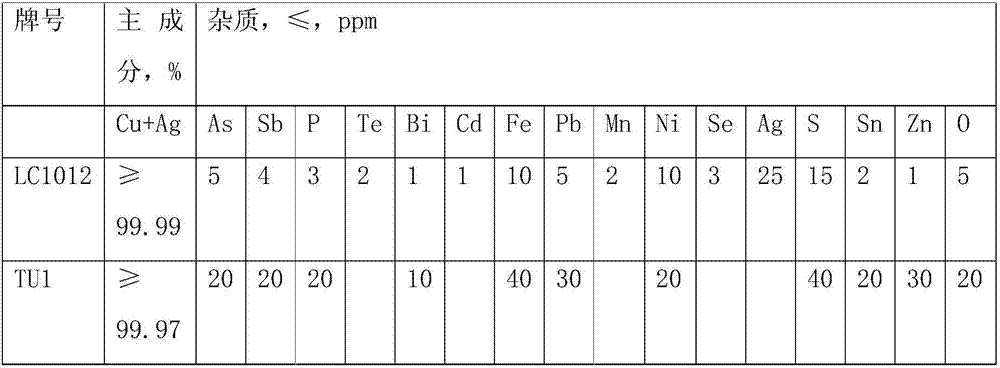

[0030] Manufacture of LC1012 alloy pipes in M state ф159×122 (inner)×895mm:

[0031] Preheating: The raw material is made of high-purity oxygen-free copper alloy, the copper content is more than 99.99%, the oxygen content is less than 5ppm, the surrounding burr is cut off, the thickness is more than 15mm, there is no copper bean or patina, dry and clean, for raw materials with copper bean or patina After removing the copper beans or verdigris, dry and clean them for later use, and then enter the preheating drying furnace for preheating. The preheating drying furnace adopts a cathode copper baking furnace, and the preheated raw materials are equal to or greater than 200°C;

[0032] Smelting: Add the preheated raw materials into the melting furnace at a feeding rate of 2 to 3 minutes per block. Slits are set on the melting furnace so that the raw materials to be added can be fed into the melting furnace through the slits. Deoxidation is not added to the melting furnace Precipi...

Embodiment 2

[0044] Preheating: The raw material is made of high-purity oxygen-free copper alloy, the copper content is more than 99.99%, the oxygen content is less than 5ppm, the surrounding burr is cut off, the thickness is more than 15mm, there is no copper bean or patina, dry and clean, for raw materials with copper bean or patina After removing the copper beans or verdigris, dry and clean them for later use, and then enter the preheating drying furnace for preheating. The preheating drying furnace adopts a cathode copper baking furnace, and the preheated raw materials are equal to or greater than 200°C;

[0045] Smelting: Add the preheated raw materials into the melting furnace at a feeding rate of 2 to 3 minutes per block. Slits are set on the melting furnace so that the raw materials to be added can be fed into the melting furnace through the slits. Deoxidation is not added to the melting furnace Precipitation deoxidation or deoxidation through charcoal diffusion to achieve low oxyge...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Crystal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com