A Laser Combined Processing Technology for Obtaining Wear-resistant and Corrosion-resistant Titanium Alloy Workpieces

A combined processing and titanium alloy technology, which is applied in the coating process and coating of metal materials, can solve the problems of application constraints, poor wear resistance and corrosion resistance, and easy peeling, so as to stabilize the internal structure and size and improve wear resistance. Corrosion, the effect of improving corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0024] Ti-6AL-4V was selected as the research object, and Ti-6AL-4V was made into a block sample of 50mm×50mm×6mm. The sample to be treated was placed in an alcohol solution and the dust and oil stains on the surface were removed by an ultrasonic cleaner.

[0025] Put the Ti-6AL-4V sample into a box-type resistance furnace SX2 10 12 for preheating (the phase transition temperature of Ti-6Al-4V is 998°C), and set the heating temperature to 900°C.

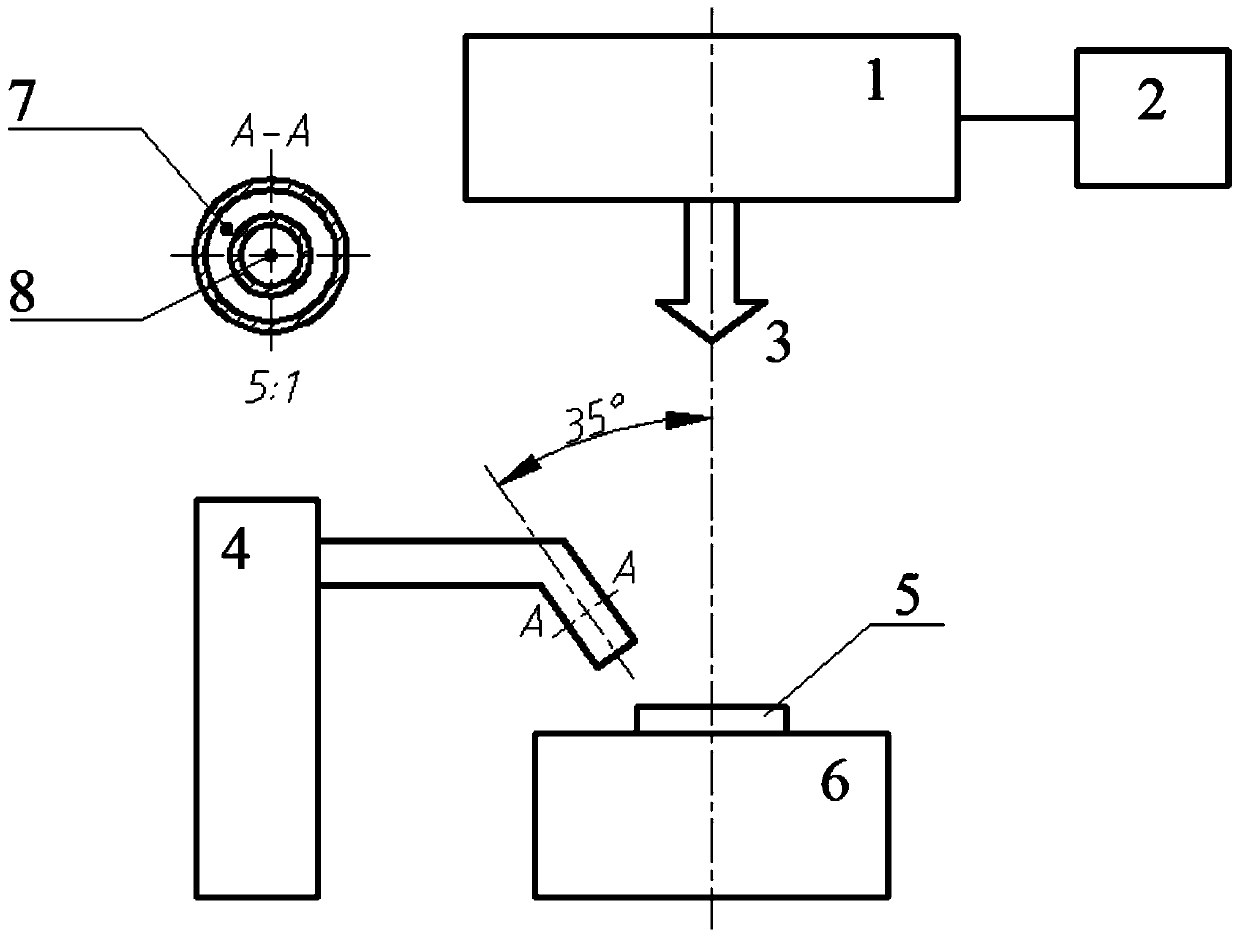

[0026] Take out the Ti-6AL-4V sample heated to 900°C and install it on the loading platform 6 of the laser shock device. The center of the laser beam spot coincides with the upper left corner of the surface to be impacted on the substrate as the starting position of the impact strengthening treatment, and the The X-axis and Y-axis directions of the area to be impacted are consistent with the X-axis and Y-axis directions of the loading platform.

[0027] Set the output power and light spot parameters of the continuous DL HL T5000 carb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com