Processing method for preparing pinctada martensii meat seasoning base material by use of strain fermentation

A technology of Hepu pearl oyster and seasoning base material, which is applied in the field of seasoning base material to achieve the effects of rich flavor components, good rehydration and good solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

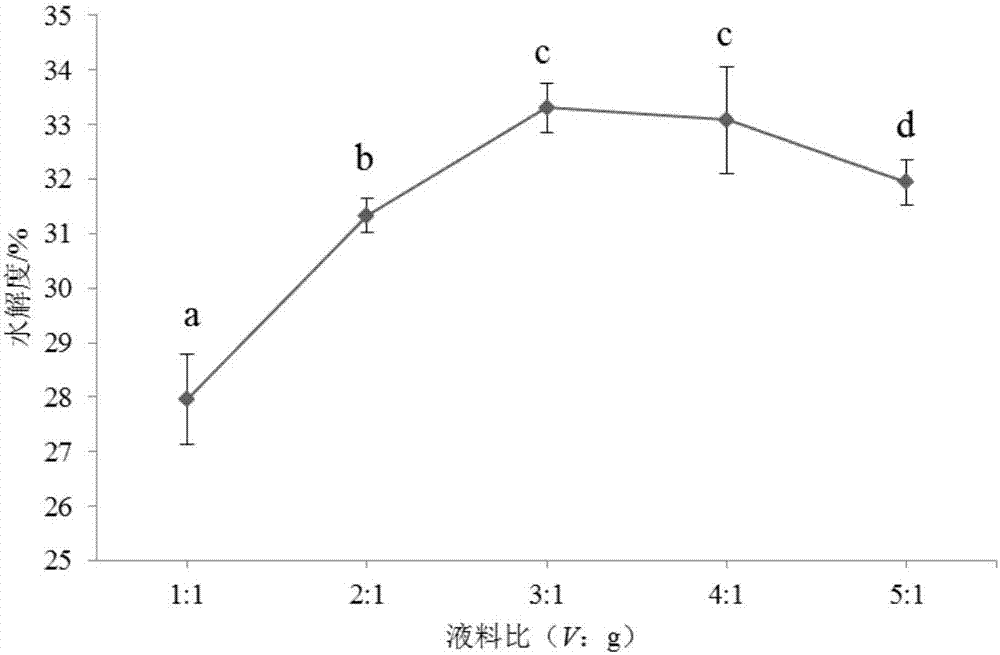

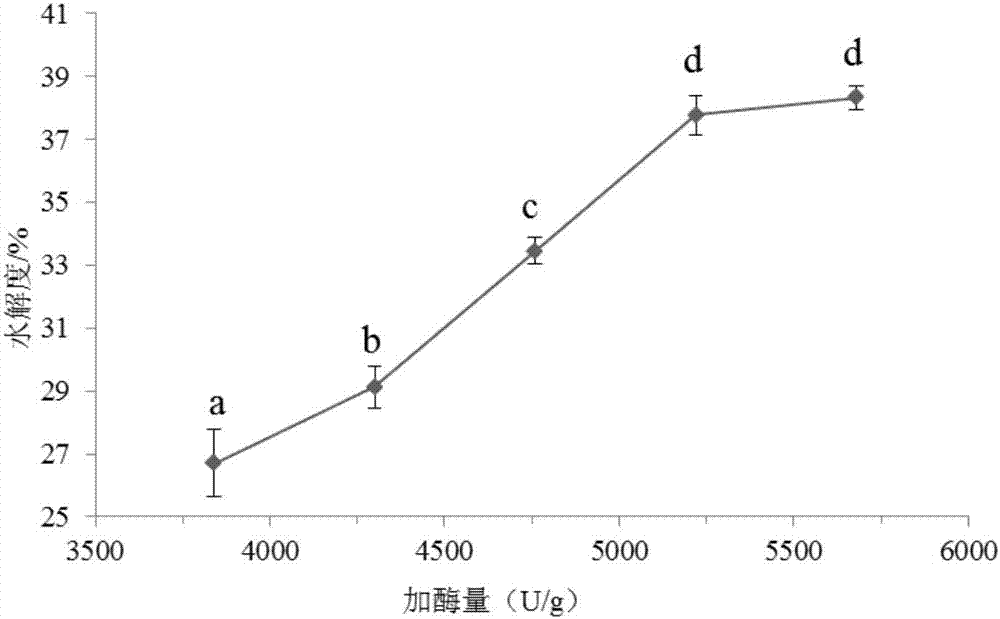

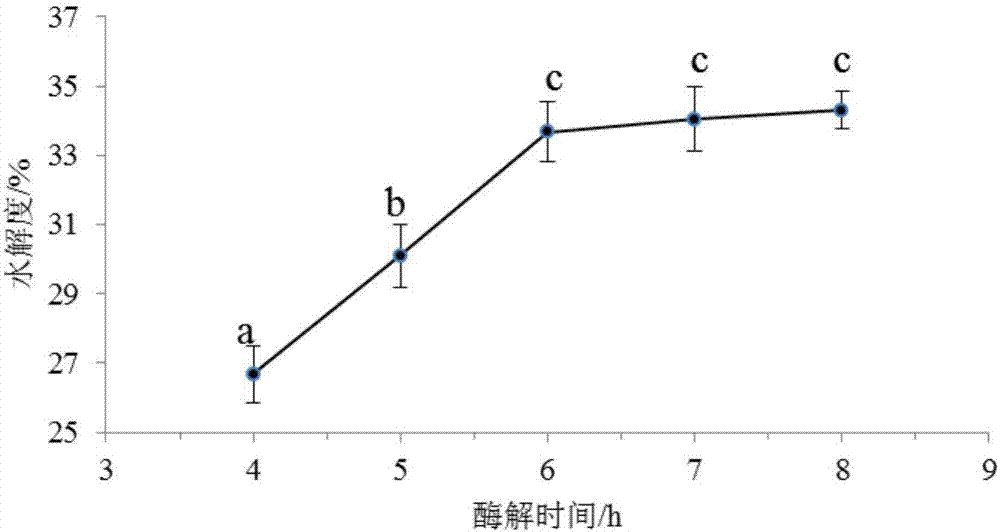

Method used

Image

Examples

Embodiment 1

[0043] The processing method for preparing the seasoning base material of Hepu pearl oyster meat by using strain fermentation provided by the present embodiment comprises the following steps:

[0044] (1) Raw material pretreatment: take the flesh of Hepu Pearl Oyster, wash it, homogenize it, and prepare Hepu Pearl Oyster Meat Homogenate Liquid according to the mass ratio of raw material and water at 1:1;

[0045] (2) Preparation of enzymatic hydrolysis solution: Add compound protease to Hepu pearl oyster meat homogenate for enzymolysis. The enzyme dosage is 3000U / g (raw material) and the enzymolysis temperature is 30°C. After adding protease, place it in a constant temperature stirring pot. After enzymatic hydrolysis for 3 hours, cool down and centrifuge for 15 minutes in a centrifuge with a rotation speed of 6000r / min;

[0046] (3) Fermentation of enzymatic hydrolyzate: get the supernatant after centrifugation to inoculate fermentation strains Aspergillus oryzae and Saccharom...

Embodiment 2

[0065] The raw material used in this embodiment is frozen Hepu pearl oyster meat, comprising the following steps:

[0066] (1) Raw material pretreatment: take the flesh of Hepu pinnacle oyster, wash it, homogenize it, and prepare Hepu pinnacle oyster meat homogenate liquid according to the mass ratio of raw material and water at 1:2;

[0067] (2) Preparation of enzymatic hydrolysis solution: Add compound protease to the homogenate of Hepu pinnacle oyster meat for enzymolysis, the enzyme dosage is 5000U / g (raw material), and the enzymolysis temperature is 38°C. After adding protease, place it in a constant temperature stirring pot for enzymolysis for 4 hours, then cool it down, and centrifuge it in a centrifuge with a rotation speed of 7500r / min for 20min;

[0068] (3) Fermentation of enzymatic hydrolyzate: get the supernatant after centrifugation to inoculate the fermented strains of Aspergillus oryzae and Saccharomyces ruxii for fermentation: add 1.5% (accounting for the tota...

Embodiment 3

[0072] The raw material that present embodiment adopts is fresh Hepu pearl oyster meat, comprises the following steps:

[0073] (1) Raw material pretreatment: take the flesh of Hepu Pearl Oyster, wash it, homogenize it, and prepare Hepu Pearl Oyster Meat Homogenate Liquid according to the mass ratio of raw material and water at 1:3;

[0074] (2) Preparation of enzymatic hydrolysis solution: Add compound protease to the homogenate of Hepu Pinctada oyster meat for enzymolysis, the enzyme dosage is 6000U / g (raw material), and the enzymolysis temperature is 45°C. After adding protease, place it in a sandwich pot for enzymolysis for 5 hours, then cool it down, and centrifuge for 30 minutes in a centrifuge with a rotation speed of 9000r / min;

[0075] (3) Fermentation of enzymatic hydrolyzate: take the supernatant after centrifugation and inoculate the fermenting strains of Aspergillus oryzae and Saccharomyces ruxii for fermentation: add 3% (accounting for the total mass of enzymolyz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com