Slump loss resistant concrete pumping aid

A concrete pump and slump-preserving technology, which is applied in the field of building materials, can solve problems such as slump loss, and achieve the effects of small slump loss, good economic and social benefits, and good concrete performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

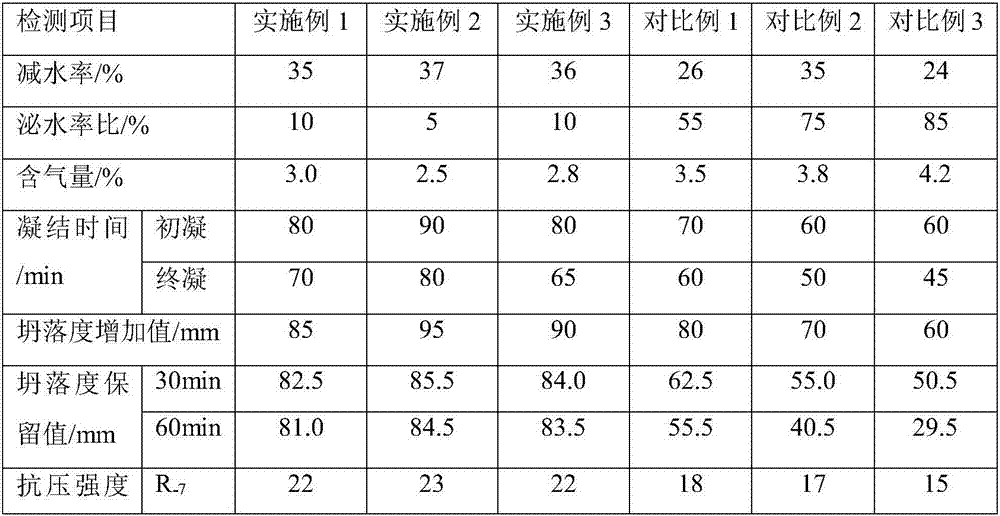

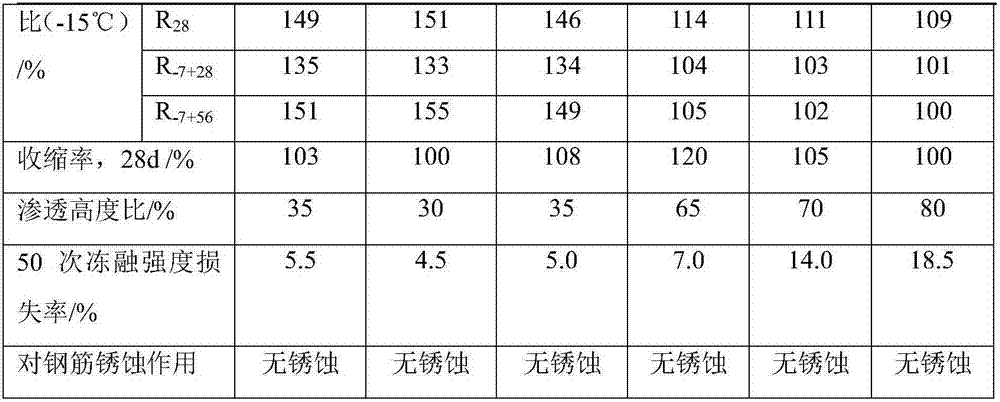

Examples

Embodiment 1

[0022] A slump-preserving concrete pumping agent, which is prepared from the following raw materials in parts by weight: 30 parts of naphthalene-based high-efficiency water reducer, 8 parts of diethanol monoisopropanolamine maleate compound, and 5 parts of glycerol carbonate , 3 parts of triethylamine, 0.6 part of simethicone, 3 parts of retarder, 0.3 part of fatty alcohol polyoxyethylene ether, and 40 parts of water.

[0023] Said, the solid content of the naphthalene-based high-efficiency water reducer is 95%, the pH value is 8-9, and the sodium sulfate content is lower than 10%.

[0024] Described, diethanol monoisopropanolamine maleate compound is made by following method: add diethanol monoisopropanolamine and maleic anhydride in reactor, add catalyzer, depressurize to 0.4MPa, heating, the temperature is controlled at 95°C, the system is kept at a constant temperature, and the acidity of the system is measured every 1h, and the reaction stops when the acid value does not ...

Embodiment 2

[0033] A slump-preserving concrete pumping agent, which is prepared from the following raw materials in parts by weight: 25 parts of naphthalene-based high-efficiency water reducer, 10 parts of diethanol monoisopropanolamine maleate compound, and 6 parts of glycerol carbonate , 4 parts of triethylamine, 0.4 part of simethicone, 5 parts of retarder, 0.2 part of fatty alcohol polyoxyethylene ether, and 50 parts of water.

[0034] Said, the solid content of the naphthalene-based high-efficiency water reducer is 95%, the pH value is 8-9, and the sodium sulfate content is lower than 10%.

[0035] Described, diethanol monoisopropanolamine maleate compound is made by following method: add diethanol monoisopropanolamine and maleic anhydride in reactor, add catalyzer, depressurize to 0.4MPa, heating, the temperature is controlled at 95°C, the system is kept at a constant temperature, and the acidity of the system is measured every 1h, and the reaction stops when the acid value does not...

Embodiment 3

[0044] A slump-preserving concrete pumping agent, which is prepared from the following raw materials in parts by weight: 20 parts of naphthalene-based high-efficiency water reducer, 12 parts of diethanol monoisopropanolamine maleate compound, and 7 parts of glycerol carbonate , 5 parts of triethylamine, 0.2 part of simethicone, 7 parts of retarder, 0.1 part of fatty alcohol polyoxyethylene ether, and 60 parts of water.

[0045] Said, the solid content of the naphthalene-based high-efficiency water reducer is 95%, the pH value is 8-9, and the sodium sulfate content is lower than 10%.

[0046] Described, diethanol monoisopropanolamine maleate compound is made by following method: add diethanol monoisopropanolamine and maleic anhydride in reactor, add catalyzer, depressurize to 0.4MPa, heating, the temperature is controlled at 95°C, the system is kept at a constant temperature, and the acidity of the system is measured every 1h, and the reaction stops when the acid value does not...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com