A fire-free permeable brick prepared from waste slag and soil and its preparation process

A preparation process and technology of permeable bricks, which are applied in the field of building materials, can solve problems such as land resources and ecological environment damage, and achieve the effects of protecting the environment, reducing costs, and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

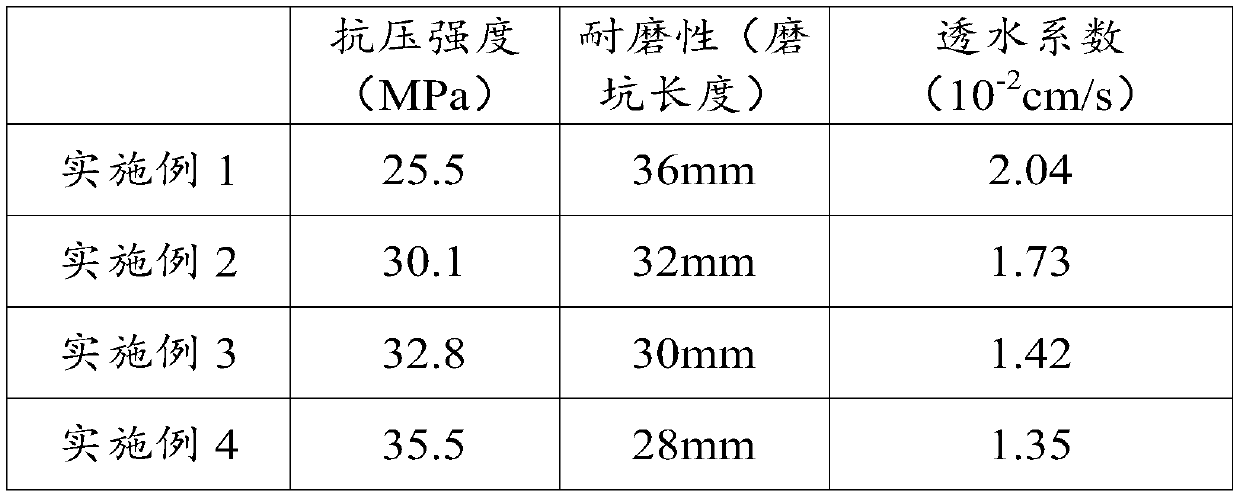

Examples

preparation example Construction

[0030] In the preparation process of soil coagulant, different additives are added according to actual needs to achieve the required performance. Further, in a preferred embodiment of the present invention, the additive includes at least one of an activator, a coagulant, and a water reducer.

[0031] After the mixture is fully mixed with the soil coagulant to obtain materials, the materials are transported to an automatic molding machine for hydraulic molding to obtain bricks. According to needs, 140 ~ 145g / m 2 Spray the dispersion containing 0.5-1.5wt% silicone waterproof emulsion (Dow Corning, IE-6683), preferably, the dispersion is concentrated polytetrafluoroethylene dispersion (Guangzhou Songbai Chemical Co., Ltd.), so that the brick has a certain Waterproof, naturally stacked for 8 to 12 hours to make permeable bricks.

[0032] The present invention also provides a non-fired permeable brick prepared from waste slag and soil, which is prepared by the above-mentioned pre...

Embodiment 1

[0035] This example provides a fire-free permeable brick prepared from waste slag and soil, which is mainly produced by the following preparation process:

[0036] Use a drum screening device to screen the sludge and soil for the first time by washing with water, and screen out large impurities such as granular stones in the sludge and soil.

[0037] A thickener is used to mix the screened mud with a flocculant to solidify and coagulate the mud.

[0038] The mixture of mud and flocculant is extruded and dewatered by stacked screw extrusion device. Continuous dehydration is realized by means of extrusion and pressure to obtain a mixture with a water content of 30%.

[0039] Fully mix the dehydrated mixture with the soil coagulant at a mass ratio of 1:3, and harden the mixture to obtain the material.

[0040] The materials are transported to the automatic molding machine for hydroforming to obtain bricks, which are naturally stacked for 10 hours to produce permeable bricks.

Embodiment 2

[0042] This example provides a fire-free permeable brick prepared from waste slag and soil, which is mainly produced by the following preparation process:

[0043] The closed drum screening device is used to screen the sludge and soil for the first time by means of water flow washing, and the large impurities such as granular stones in the sludge and soil are screened out.

[0044] The sandy muddy water obtained from the first screening is screened for the second time by using a water wheel sand collecting device to remove the gravel and obtain mud and dregs with smaller particle sizes.

[0045] A thickener is used to mix the screened mud with a flocculant to solidify and coagulate the mud.

[0046] The mixture of mud and flocculant is extruded and dewatered by stacked screw extrusion device. Continuous dehydration is realized by means of extrusion and pressure to obtain a mixture with a water content of 20%.

[0047] Fully mix the dehydrated mixture with the soil coagulant ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com