A kind of ultra-fine-grained high-performance ti(c,n)-tib2-wc-tac composite cermet cutting tool and its preparation method

A -tib2-wc-tac, composite metal technology, applied in the field of new materials, can solve the problems of low ceramic phase solubility, reduced grain boundary bonding force, grain coarsening, etc., to achieve cutting performance advantages, dense tissue and uniform distribution , the effect of ultra-fine grain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

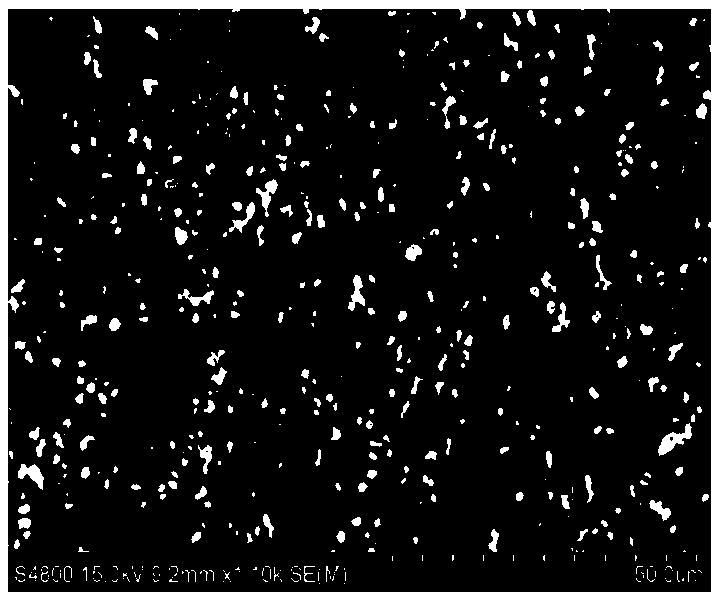

Embodiment 1

[0023]The raw material powders according to the component ratios in Attached Table 1 were put into a drum-type ball mill and dry-mixed for 24 hours, the speed of the ball mill was 400r / min, the grinding medium was zirconia balls with a diameter of 8mm, and the ball-to-material ratio was 8:1. After the powder is evenly mixed, take it out and pass through a 100-mesh sieve, then weigh a certain amount of powder and put it into a cylindrical graphite mold with a diameter of 20mm for pre-pressing for 10min at a pressure of 20MPa. Then put the graphite mold with the powder compact into the vacuum hot pressing sintering furnace and heat it to the set temperature (from room temperature to 800°C, the heating rate is 10°C / min; above 800°C, the heating rate is 5°C / min), Keep warm for 60 minutes and then cool down with the furnace. The sintering temperature ranges from 1400°C to 1800°C. In order to obtain high-density materials, a unidirectional pressure of 20MPa is applied between 900°C ...

Embodiment 2

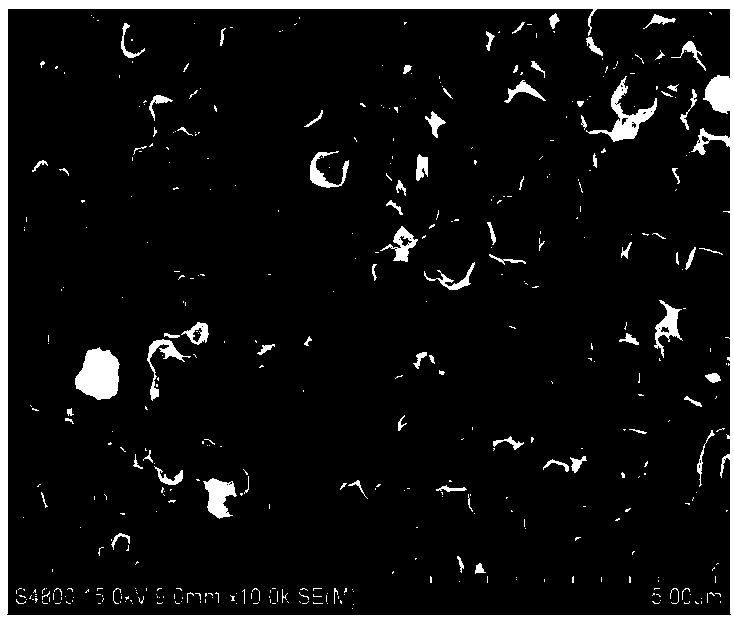

[0025] The tool material composition is: Co: 8wt.% (purity 99wt.%, particle size<1μm), Ti: 62wt.% (purity 99.9wt.%, particle size<0.8μm), C: 3wt.% (purity 98wt.%, particle size<1μm), BN: 12wt.% (purity 99wt.%, particle size<0.5μm), WC: 3wt.% (purity 99.9wt.%, particle size<0.4 μm), TaC: 12wt.% (purity 99.9wt. %, particle size <0.4μm).

[0026] The specific preparation process is as follows: put the raw material powder into a roller ball mill and dry mix for 24 hours, the speed of the ball mill is 400r / min, the grinding medium is zirconia balls with a diameter of 8mm, and the ball-to-material ratio is 8:1. After the powder is evenly mixed, take it out and pass through a 100-mesh sieve, then weigh a certain amount of powder and put it into a cylindrical graphite mold with a diameter of 20mm for pre-pressing for 10min at a pressure of 20MPa. Then put the graphite mold with the powder compact into the vacuum hot pressing sintering furnace and heat it to the set temperature (from ...

Embodiment 3

[0029] The tool material composition is: Co: 8wt.% (purity 99wt.%, particle size<1μm), Ti: 62wt.% (purity 99.9wt.%, particle size<0.8μm), C: 3wt.% (purity 98wt.%, particle size<1μm), BN: 12wt.% (purity 99wt.%, particle size<0.5μm), WC: 6wt.% (purity 99.9wt.%, particle size<0.4 μm), TaC: 9wt.% (purity 99.9wt. %, particle size <0.4μm).

[0030] The specific preparation process is as follows: put the raw material powder into a roller ball mill and dry mix for 24 hours, the speed of the ball mill is 400r / min, the grinding medium is zirconia balls with a diameter of 8mm, and the ball-to-material ratio is 8:1. After the powder is evenly mixed, take it out and pass through a 100-mesh sieve, then weigh a certain amount of powder and put it into a cylindrical graphite mold with a diameter of 20mm for pre-pressing for 10min at a pressure of 20MPa. Then put the graphite mold with the powder compact into the vacuum hot pressing sintering furnace and heat it to the set temperature (from r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com