Isomorphous, high performance cobalt nickel @ cobalt nickel core-shell structure material and preparation method and application thereof

A core-shell structure, nickel cobalt oxide technology, applied in nanotechnology for materials and surface science, hybrid/electric double-layer capacitor manufacturing, nanotechnology, etc. Problems such as poor capacitance and cycle stability, poor rate performance, etc., achieve the effects of easy regulation, mild conditions, and convenient post-processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The invention provides a method for preparing isomorphic, high-performance nickel cobalt oxide@nickel cobalt oxide core-shell structure material, including:

[0028] 1) nickel foam is carried out pretreatment;

[0029] 2) Mix nickel salt, cobalt salt, urea, and solvent to prepare solution A, then place solution A under airtight conditions for hydrothermal reaction, then separate solid from liquid and wash and dry the separated solid to prepare Foamed nickel covering the precursor;

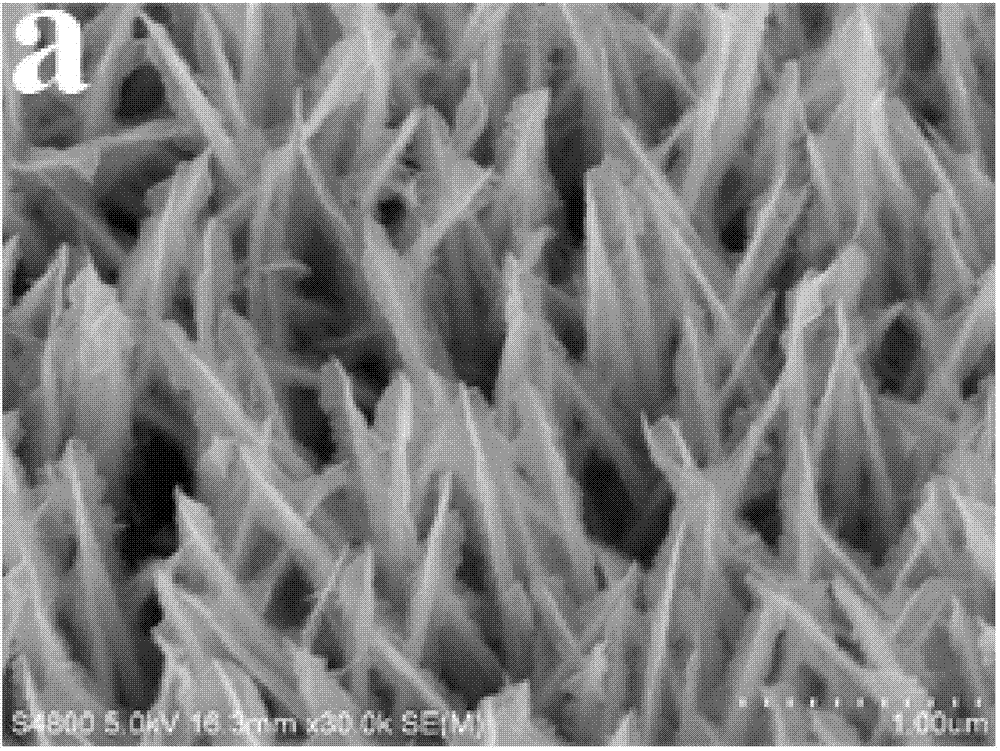

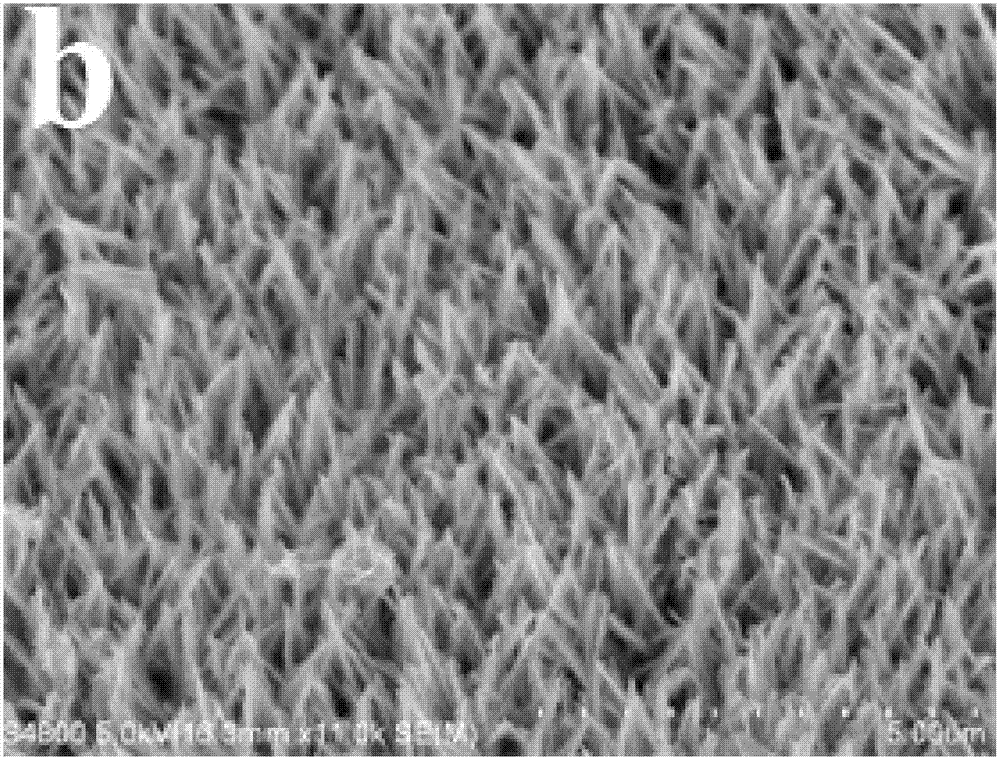

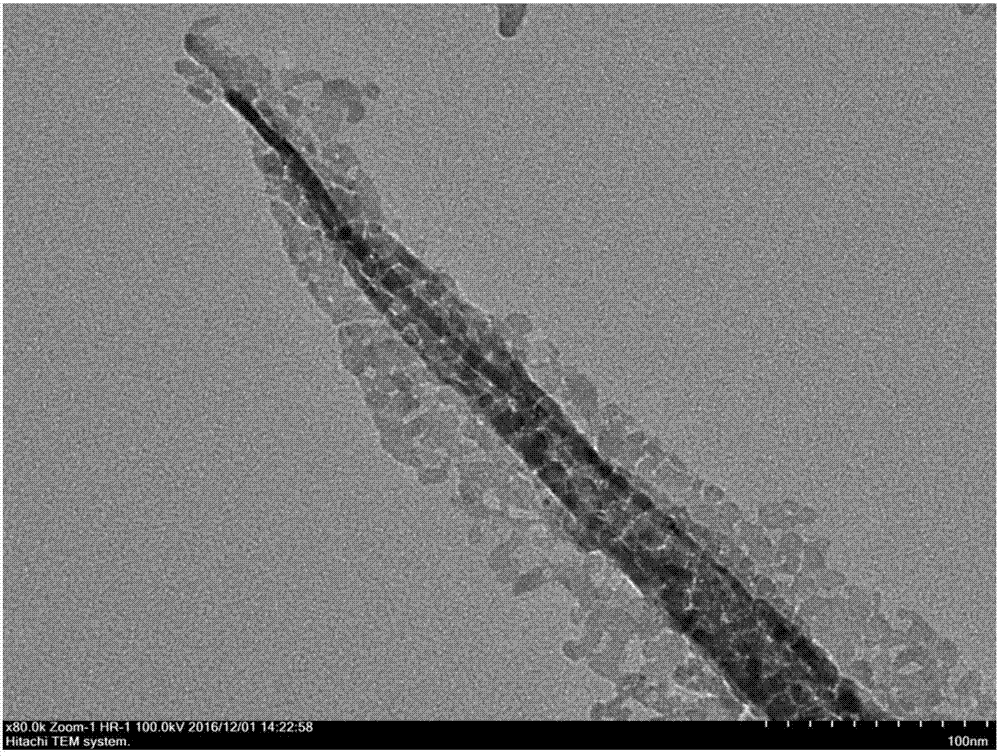

[0030] 3) Mix nickel salt, cobalt salt, hexamethylenetetramine (MHT), and solvent to prepare solution B, then place the foamed nickel covering the precursor and solution B under airtight conditions for hydrothermal reaction, and then Solid-liquid separation and the separated solids are washed, dried, and calcined to obtain isomorphic, high-performance NiCo 2 o 4 @NiCo 2 o 4 Core-shell structural material.

[0031] In step 1) of the present invention, the specific operation of pretreatm...

Embodiment 1

[0054] 1) Soak foamed nickel (2cm in length, 3cm in width, 0.8mm in thickness, and 0.254g in weight) in 3mol / L hydrochloric acid solution at 20°C for 15 minutes, and ultrasonically clean it for 14 minutes to obtain foamed nickel after cleaning.

[0055] 2) 0.925mmol Ni(NO 3 ) 2 ·6H 2 O, 1.85mmol Co(NO 3 ) 2 ·6H 2 O and 3.7mmol urea were dissolved in 15mL deionized water and 3mL ethanol, and stirred for 8min to obtain solution A. Transfer solution A to a 50mL reaction kettle, put the cleaned foamed nickel into solution A, and seal it under water at 120°C. After thermal reaction for 4 h, cooling to 25 °C, the nickel foam covering the sample was taken out, washed twice with deionized water and ethanol, and then dried at 60 °C for 8 h to obtain the nickel foam covering the precursor.

[0056] 3) Add 0.8mmol Ni(NO 3 ) 2 ·6H 2 O, 1.8mmol Co(NO 3 ) 2 ·6H 2 O and 5.2mmol MHT were dissolved in 15mL deionized water and 8mL ethanol, stirred for 10min to obtain solution B, solu...

Embodiment 2

[0058] 1) Soak foamed nickel (1.8cm in length, 2.9cm in width, 0.5mm in thickness, and 0.205g in weight) in 3mol / L, 10°C hydrochloric acid solution for 10 minutes, and ultrasonically clean it for 13 minutes to obtain foamed nickel after cleaning .

[0059] 2) Add 1mmol Ni(NO 3 ) 2 ·6H 2 O, 2mmol Co(NO 3 ) 2 ·6H 2 O and 4mmol urea were dissolved in 20mL deionized water and 5mL ethanol, and stirred for 10min to obtain solution A. Transfer solution A to a 50mL reaction kettle, put the cleaned foamed nickel into solution A, and seal it under 120°C for hydrothermal React for 5 hours, cool to 25°C, take out the nickel foam covering the sample, wash twice with deionized water and ethanol, and then dry at 60°C for 12 hours to obtain the nickel foam covering the precursor.

[0060] 3) Add 1mmol Ni(NO 3 ) 2 ·6H 2 O, 2mmol Co(NO 3 ) 2 ·6H 2 O and 5.5mmol MHT were dissolved in 20mL deionized water and 10mL ethanol, stirred for 15min to obtain solution B, solution B was transfe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com