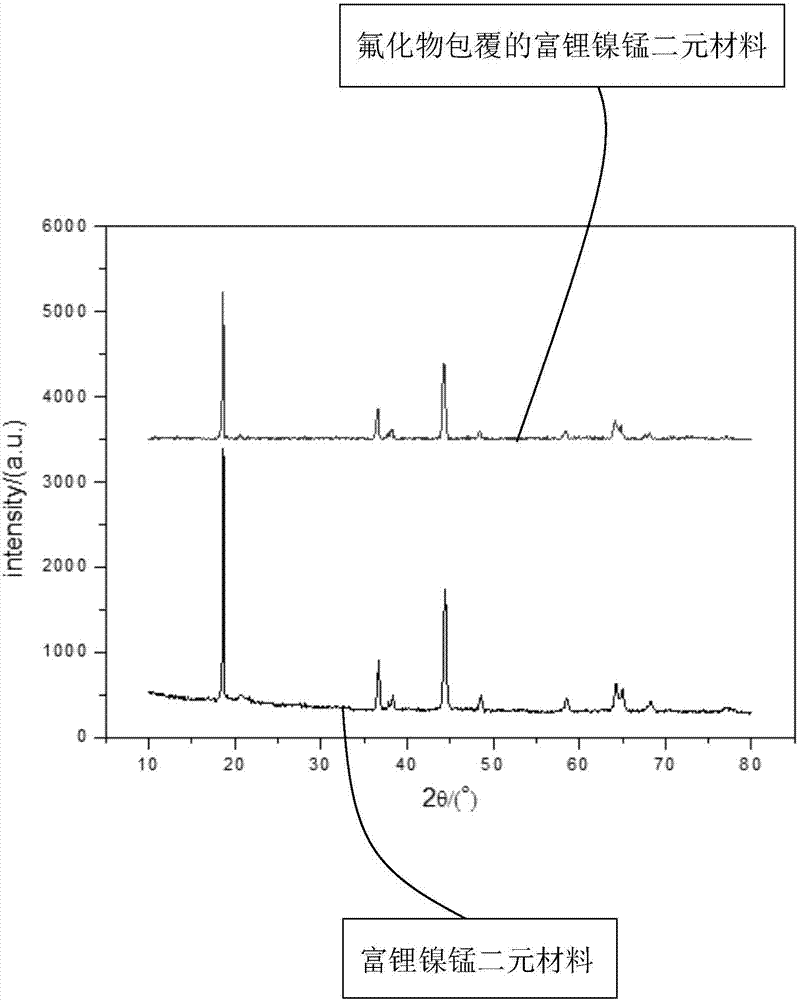

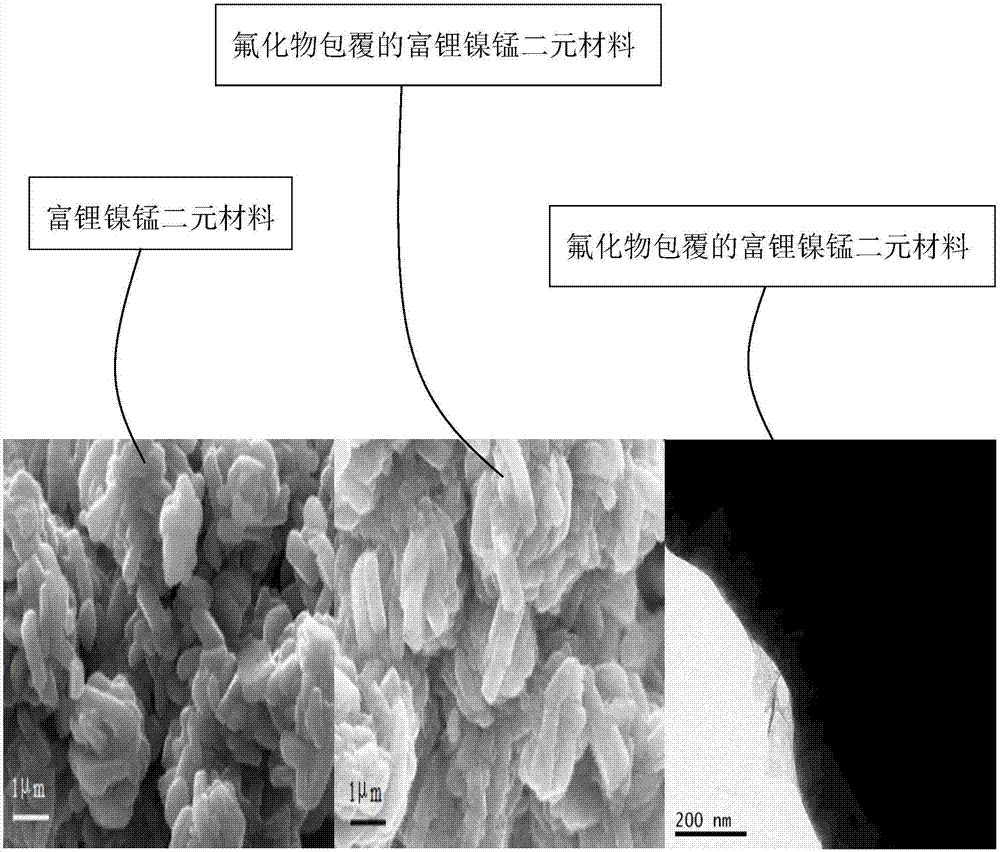

Preparation method of fluoride-coated lithium-rich nickel manganese binary material

A binary material, lithium-rich nickel technology, used in electrical components, secondary batteries, active material electrodes, etc., can solve problems affecting discharge capacity, cycle life, electrochemical performance, etc., and achieve the effect of low cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] The invention provides a method for preparing a fluoride-coated lithium-rich nickel-manganese binary material, comprising the following steps:

[0024] Step 1: dissolving soluble nickel salt and soluble manganese salt in deionized water to form a first mixture;

[0025] Step 2: dissolving the soluble carbonate in deionized water, and adding ammonia water to form a second mixture;

[0026] Step 3: Place the first mixture and the second mixture in the container and mix them uniformly at the first preset temperature to perform the first reaction for the first preset time to obtain the first product, and then wash the first product and obtain the precursor after drying;

[0027] Step 4: uniformly mixing the lithium salt and the precursor obtained in step 3 to form a third mixture, and then sintering the third mixture at a high temperature to obtain a lithium-rich nickel-manganese binary material;

[0028] Step 5: dissolving the soluble aluminum salt and the soluble fluori...

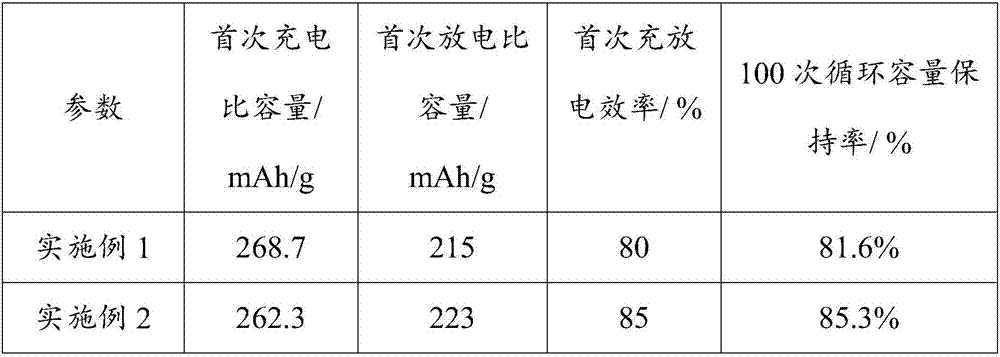

Embodiment 1

[0039] Step 1: dissolving nickel sulfate and manganese sulfate in deionized water to form a first mixture, wherein the molar ratio of nickel element in nickel sulfate and manganese element in manganese sulfate is 0.345:0.655, nickel and manganese ions in the first mixture The total concentration is 2mol / L.

[0040] Step 2: dissolving sodium carbonate in deionized water, and adding ammonia water to form a second mixture, the concentration of sodium carbonate in the second mixture is: 2mol / L, and the concentration of ammonia water is: 0.2mol / L.

[0041] Step 3: Place the first mixture and the second mixture in a container and uniformly mix them together at 55°C for the first reaction for 16 hours to obtain the first product, wherein the pH value of the first product is 8.5, and then The first product is sequentially washed with deionized water and dried to obtain a precursor.

[0042] Step 4: the lithium carbonate and the precursor obtained in step 3 are uniformly mixed according...

Embodiment 2

[0046] Step 1: dissolving nickel sulfate and manganese sulfate in deionized water to form a first mixture, wherein the molar ratio of nickel element in nickel sulfate and manganese element in manganese sulfate is 0.345:0.655, nickel and manganese ions in the first mixture The total concentration is 2mol / L.

[0047] Step 2: dissolving sodium carbonate in deionized water, and adding ammonia water to form a second mixture, the concentration of sodium carbonate in the second mixture is: 2mol / L, and the concentration of ammonia water is: 0.2mol / L.

[0048] Step 3: Place the first mixture and the second mixture in a container and uniformly mix them together at 55°C for the first reaction for 16 hours to obtain the first product, wherein the pH value of the first product is 8.5, and then The first product is sequentially washed with deionized water and dried to obtain a precursor.

[0049] Step 4: the lithium carbonate and the precursor obtained in step 3 are uniformly mixed accordi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com