Underwater-non-dispersing non-shrinking grouting material

A non-shrinkage, grouting material technology, applied in the field of new materials, can solve the problems of unsatisfactory durability and poor stability, and achieve the effects of excellent strength, improved anti-dispersion performance, good fluidity and groutability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

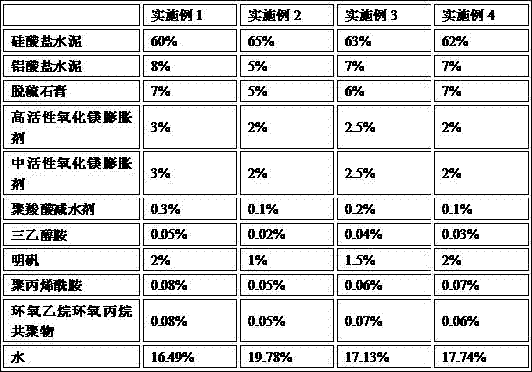

[0027] Embodiments 1-4: An underwater non-dispersing and non-shrinking grouting material.

[0028] An underwater non-dispersing and non-shrinking grouting material, the raw material formula of the slurry is composed of the following materials in mass percentage.

[0029]

[0030] A preferred embodiment is: the Portland cement is Huaihai Zhonglian P.O.42.5 cement, and the 28d strength is 49.9MPa.

[0031] A preferred embodiment is: the aluminate cement is Zhengzhou Yuxiang CA-50.

[0032] A preferred embodiment is: the gypsum used is desulfurized gypsum from Xuzhou Guohua Power Plant.

[0033] A preferred embodiment is: the calcination temperature of the high-activity magnesium oxide expansion agent is 700°C, and the specific surface area is 400m 2 / Kg.

[0034] A preferred embodiment is: the calcination temperature of the medium active magnesium oxide expansion agent is 900°C, and the specific surface area is 450 m 2 / Kg.

[0035] A preferred embodiment is: the trietha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com