Template agent for antireflection film coating liquid as well as preparation method and application of template agent

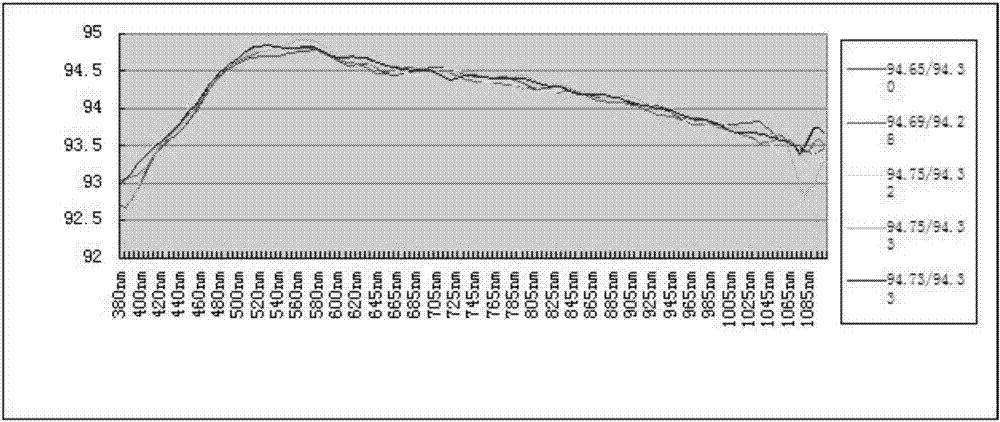

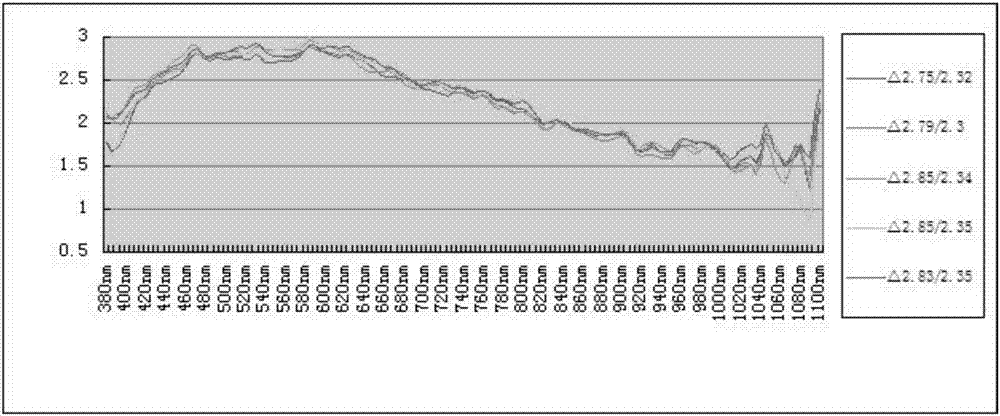

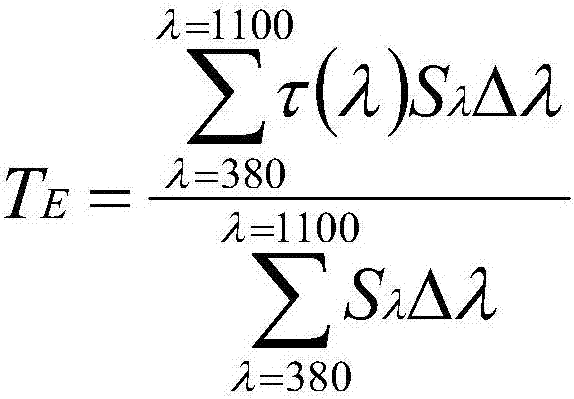

A technology of coating solution and template agent, which is applied in the direction of coating to achieve the effects of improving development efficiency, enhancing stability, improving anti-reflection rate and anti-fouling performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0053] The preparation method of the silica sol is as follows: alkoxysilane and solvent are placed in a reaction container, and a catalyst is added to react at room temperature -90°C. The time for adding the catalyst is 5min-2h, and the temperature is lowered to room temperature after 2-8h of reaction. Filter to obtain silica sol;

[0054] The preparation method of the anti-reflection and anti-reflection coating solution: put the synthesized template agent and the synthesized silica sol in a reaction container for mixing, then add a silane coupling agent to stir, heat for a heat preservation reaction, and the heat preservation reaction time is 2-8h, then cooled to room temperature, and diluted with a diluent to a coating solution with a solid content of 3-6% by weight.

[0055] In the present invention, the obtained coating solution is coated on a glass substrate by any coating method in spray coating, dip coating, pulling, roll coating, spin coating, flow coating and brush co...

Embodiment 1

[0058] (1) Preparation method of templating agent

[0059] (1) Add 330g of isopropanol to a 500ml four-neck flask equipped with a thermometer, an electric stirrer, a condenser tube and a constant pressure funnel, start stirring and heating; when the temperature reaches 75°C, add 4g of azobisisobutyronitrile , after the temperature stabilized, began to add three kinds of monomers weighed in advance, said three kinds of monomers included 32g methyl methacrylate, 8g methacrylic acid and 20g hydroxyethyl acrylate, said three kinds of monomers were added dropwise 3h, after the dropwise addition is completed, keep warm for 6h;

[0060] (2) Cool down to 40° C., add 6 g of ammonia water with a mass concentration of 25%, adjust the pH to 8, filter, and discharge to obtain a template agent.

[0061] Wherein, the mass ratios of the three monomers, solvent, initiator and auxiliary agent to the whole system are respectively 15.0% for the three monomers, 82.5% for the solvent, 1.0% for the...

Embodiment 2

[0100] (1) Preparation method of templating agent

[0101] (1) Add 200g of isopropanol and 50g of propylene glycol methyl ether into a 500ml four-neck flask equipped with a thermometer, an electric stirrer, a condenser tube and a constant pressure funnel, start stirring and heating; when the temperature reaches 80°C, add 4g of azo Diisobutyronitrile, after the temperature stabilized, began to add three or more pre-weighed monomers, said three or more monomers including 25g methyl methacrylate, 8g methacrylic acid, 15g butyl acrylate and 12g Hydroxyethyl acrylate, the three or more monomers are added dropwise for 2 hours, and after the dropwise addition is completed, the insulation reaction is carried out for 5 hours;

[0102] (2) Cool down to 40° C., add 6 g of ammonia water with a mass concentration of 25%, adjust the pH to 7, filter, and discharge to obtain a template.

[0103] Wherein, the mass ratio of the above three kinds of monomers, solvents, initiators and auxiliary ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com