Automatic screen changing device for multiple layers of filter screens for PET plastic flat wire drawing machine

A flat wire drawing machine and automatic screen changing technology, which is applied in the field of plastic processing equipment, can solve problems such as difficulty in meeting high requirements for product quality, clogging of melt extrusion outlets, and reduced pass rate of melt materials, etc., so as to prolong the time for cleaning and changing screens , avoid blockage, maximize the effect of opening time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

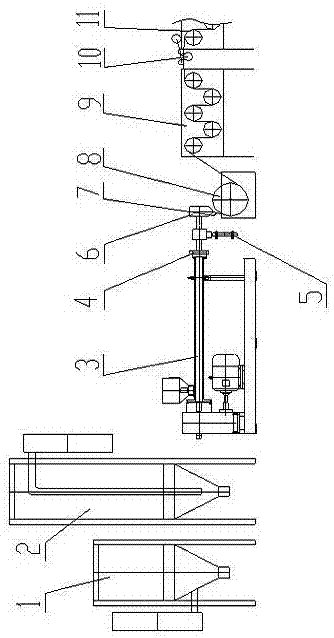

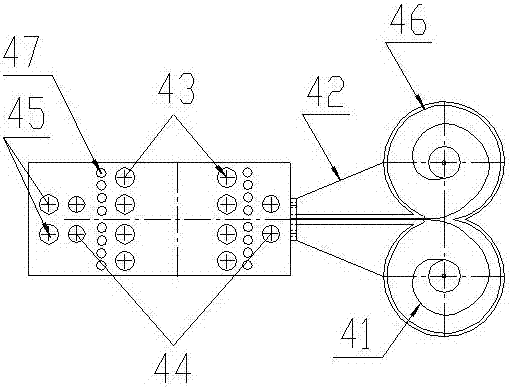

[0022] Such as figure 1 As shown, the present embodiment is a kind of PET plastic flat wire drawing machine multi-layer filter screen automatic screen changing device, is arranged on the plastic flat wire production line, comprises crystallization tower unit 1, drying tower unit 2, and molding equipment is from plastic extruding device 3, the raw material enters from the feed hopper of the plastic extrusion device 3, passes through the extruder screw to the filter screen automatic screen changer 4, and then enters the casting die 6 through the metering pump 5, and the casting die 6 is equipped with The high-voltage electrostatic generator 7, PET molten material enters the film cooling and shaping drum 8 through the high-voltage electrostatic generator 7, and is introduced into the wire cutting mechanis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com