Ostrich meat ready-to-eat flavored products and preparation method thereof

A technology of ostrich meat and flavor, applied in the direction of bacteria, food ingredients, and yeast-containing food ingredients used in food preparation, can solve the problems of low public acceptance, poor flavor quality, limited water holding capacity, etc., to avoid color Effects of browning and microbial contamination, prevention of fat oxidation and rancidity, and improvement of elasticity and tenderness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] An ostrich meat ready-to-eat flavor product (shredded meat) of the present invention includes ostrich meat, and the rest of the ingredients are based on the weight of the ostrich meat, including: 0.01wt% sodium nitrite, 0.01wt% tea polyphenols, 0.3wt% phosphoric acid Compound salt, 2wt% star anise, 2wt% cinnamon, 1.6wt% prickly ash, 1wt% fennel, 1wt% galangal, 0.8wt% kangaroo, 2wt% cloves, 0.8wt% tangerine peel, 2wt% % green onions, 1.6wt% fresh ginger, 1.0wt% liquor, 1.0wt% light soy sauce, 4.0wt% salt, 0.5wt% monosodium glutamate, 0.5wt% white sugar.

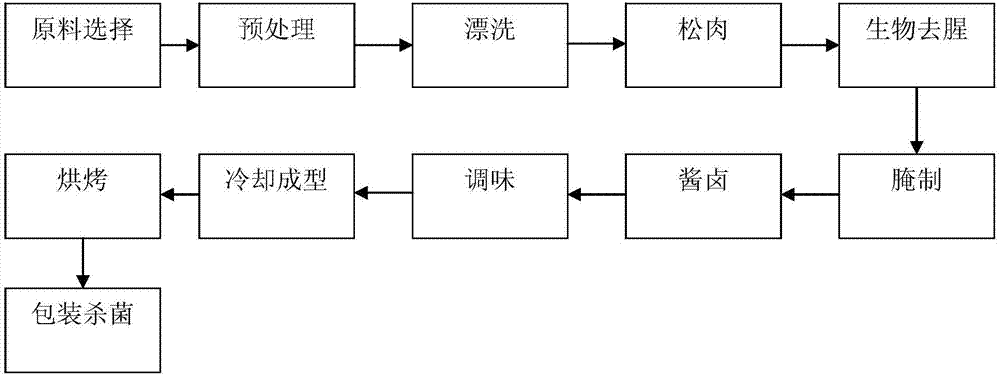

[0035] A kind of preparation method of above-mentioned ostrich meat ready-to-eat flavor product, see figure 1 , including the following steps:

[0036] (1) Preparation of mixed fermentation broth: Inoculate Debaryomyces hansenii W08 (Debaryomyces hansenii) into PDA medium for fermentation (fermentation temperature is 28°C, time is 24h) to obtain a viable bacterial concentration of 1.68×10 8 CFU / mL of Debaryomyces hans...

Embodiment 2

[0047] An ostrich meat ready-to-eat flavor product (meat piece) of the present invention comprises ostrich meat, and the rest of the ingredients are based on the weight of the ostrich meat, including: 0.01wt% sodium nitrite, 0.01wt% tea polyphenols, 0.3wt% phosphoric acid Compound salt, 2wt% star anise, 2wt% cinnamon, 1.6wt% prickly ash, 1wt% fennel, 1wt% galangal, 0.8wt% kangaroo, 2wt% cloves, 0.8wt% tangerine peel, 2wt% % green onions, 1.6wt% fresh ginger, 1.0wt% liquor, 1.0wt% light soy sauce, 4.0wt% salt, 0.5wt% monosodium glutamate, 0.5wt% white sugar.

[0048] A preparation method of the above-mentioned ostrich meat instant flavor product, comprising the following steps:

[0049] (1) Preparation of mixed fermentation broth: Inoculate Debaryomyces hansenii W08 (Debaryomyces hansenii) into PDA medium for fermentation (fermentation temperature is 28°C, time is 24h) to obtain a viable bacterial concentration of 1.68×10 8 CFU / mL of Debaryomyces hansenii fermentation broth. ...

Embodiment 3

[0059] Example 3, the formula and process are the same as those in Example 1, wherein the fermentation broth of Debaria hansenii and the fermentation broth of Lactobacillus sake are mixed according to the volume ratio of 0.5:1 to obtain a mixed fermentation broth.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com