A kind of polybutylene succinate composite carbon source filter material and its preparation method and application

A polybutylene succinate and composite carbon source technology, applied in separation methods, chemical instruments and methods, filtration and separation, etc., can solve problems such as unfavorable denitrification and SS removal, and achieve lower prices, lower effluent DOC, The effect of high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

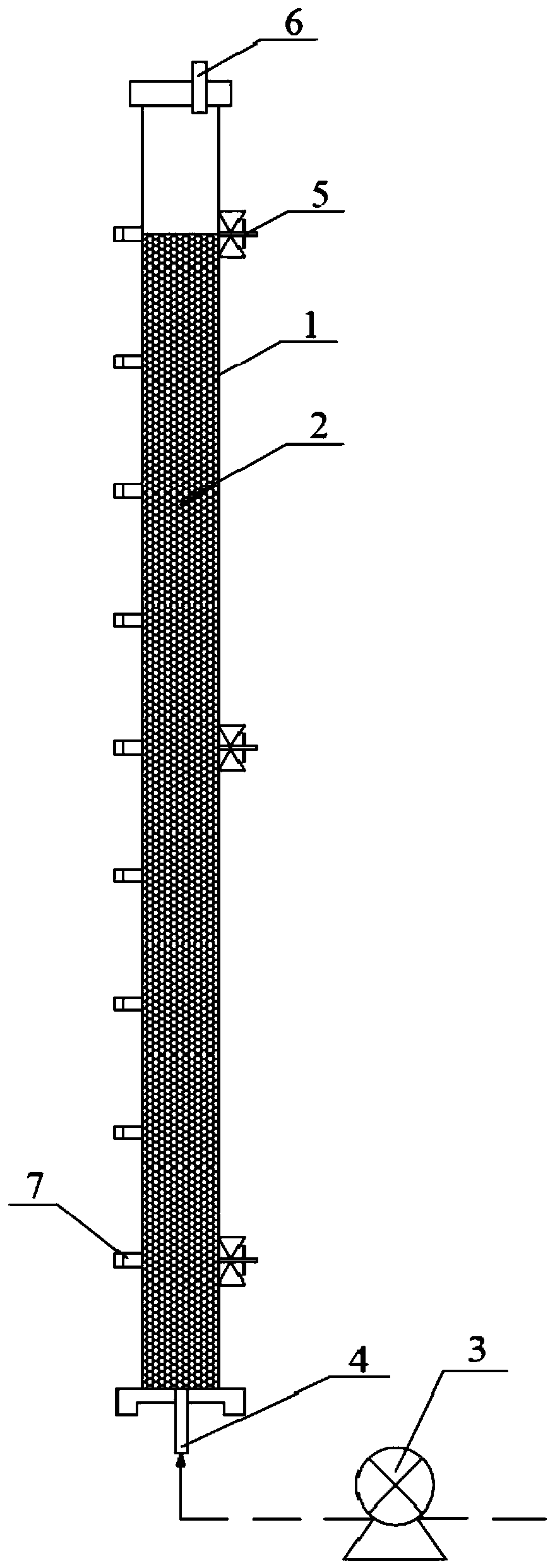

Image

Examples

Embodiment 1

[0040] In the first aspect, the preparation of novel PBS / BP filter material is carried out.

[0041] The PBS / BP filter material comprises the following components by weight percentage: PBS (49.9%, Anqing Hexing Chemical Co., Ltd., model is Z101), bamboo powder (49.9%) and additive (0.2%, foaming agent, Gongyi City Tai Power Chemical Trading Co., Ltd., model AC, gas output is 220ml / g, decomposition temperature is 200°C). The preparation steps are:

[0042] Step 1: Take and weigh PBS, bamboo powder and additives to a mixer for melting and blending according to the component formula to obtain a blend;

[0043] The bamboo powder described in step one is 100 order moso bamboo powder, and used additive is whipping agent. The melting and blending temperature of the kneader is 135-145°C, the motor speed is set to 8r / s when feeding, and the motor speed is adjusted to 12r / s after all the components are added, and the mixed filler is taken out after 15 minutes;

[0044] Step 2: Put th...

Embodiment 2

[0052] In the first aspect, the preparation of novel PBS / LP filter material is carried out.

[0053] The new PBS / LP filter material comprises the following components by weight percentage: PBS (49.9%, Anqing Hexing Chemical Co., Ltd., model Z101), longan kernel powder (49.9%) and additives (0.2%, blowing agent, Gongyi City Taili Chemical Trading Co., Ltd., model AC, gas generation is 220ml / g, decomposition temperature is 200°C). The preparation steps are:

[0054] Step 1: Take and weigh PBS, longan seed powder and additives according to the component formula and melt and blend them in a mixer to obtain a blend.

[0055] The longan seed powder described in step one is 100 orders, and the used additive is foaming agent. The melting and blending temperature of the kneader is 135-145°C, and the motor speed is set to 8r / s when feeding. After all the components are added, the motor speed is adjusted to 12r / s, and the mixed filler is taken out after 15 minutes.

[0056] Step 2: Pu...

Embodiment 3

[0064] In the first aspect, the preparation of novel PBS / BP / starch filter material is carried out.

[0065] Novel PBS / BP / starch filter material comprises the following components by weight percentage: PBS (33.3%, Anqing Hexing Chemical Co., Ltd., model is Z101), bamboo powder (33.3%), longan kernel powder (33.2%) and additive (0.2%, foaming agent, Gongyi City Taili Chemical Trade Co., Ltd., model AC, gas production is 220ml / g, decomposition temperature is 200°C). The preparation steps are:

[0066] Step 1: Take and weigh PBS, bamboo powder, longan seed powder and additives according to the component formula to a mixer for melting and blending.

[0067] The bamboo powder described in step one is 100 mesh moso bamboo powder, and the longan nuclear powder is also 100 mesh, and the used additive is foaming agent. The melting and blending temperature of the kneader is 135-145°C, and the motor speed is set to 8r / s when feeding. After all the components are added, the motor speed i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com