Preparation method and application of graphene oxide separation membrane

A technology of graphene dispersion and separation membrane, which is applied in chemical instruments and methods, semi-permeable membrane separation, membrane technology, etc., can solve the problems of unsuitability for industrial scale production, degradation of separation performance, thick film thickness, etc., and achieve good results Socio-economic benefits and value, great commercial value, effect of controllable area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] 1) Preparation of graphene oxide dispersion:

[0026] Disperse the graphene oxide powder prepared above in deionized water, ultrasonically disperse, and prepare a 0.1 g / L graphene oxide dispersion

[0027] 2) Preparation of graphene oxide separation membrane

[0028] Take 5μl of the graphene oxide dispersion and add it to 400ml of deionized water, at a cross-flow pressure of 1bar, a cross-flow flow rate of 0.35LPM, and an effective membrane area of 3.14cm 2 , PC membrane with a pore size of 200nm, cross-flow membrane formation for 15min, and an ultra-thin graphene oxide separation membrane was prepared.

Embodiment 2

[0030] 1) Preparation of graphene oxide dispersion:

[0031] Disperse the graphene oxide powder prepared above in deionized water, ultrasonically disperse, and make a 0.4g / L graphene oxide dispersion;

[0032] 2) Preparation of graphene oxide separation membrane:

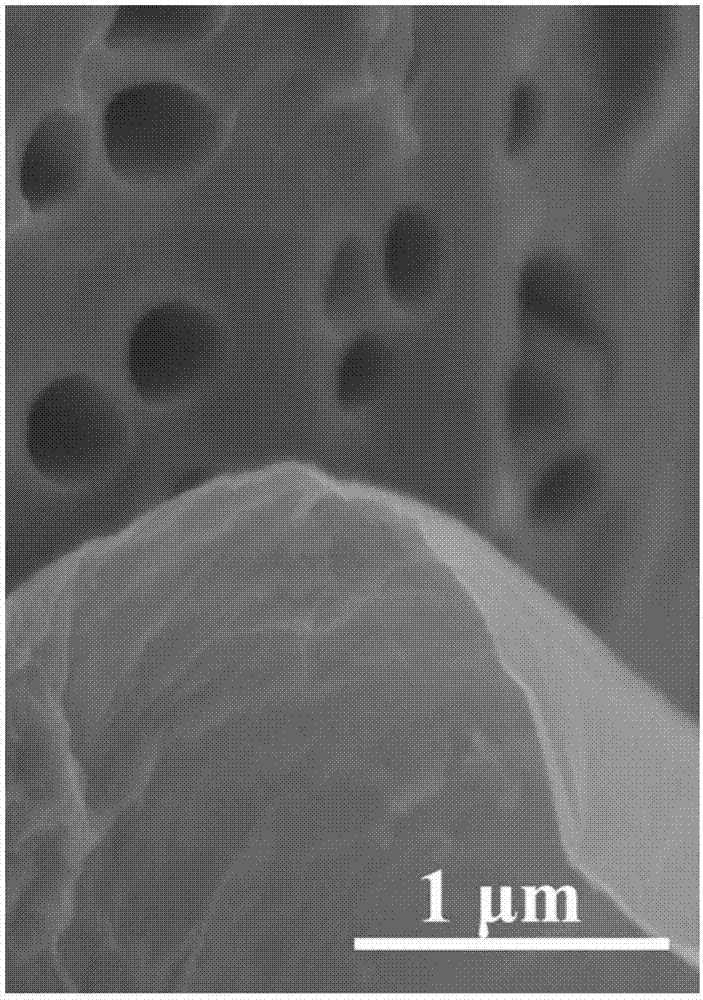

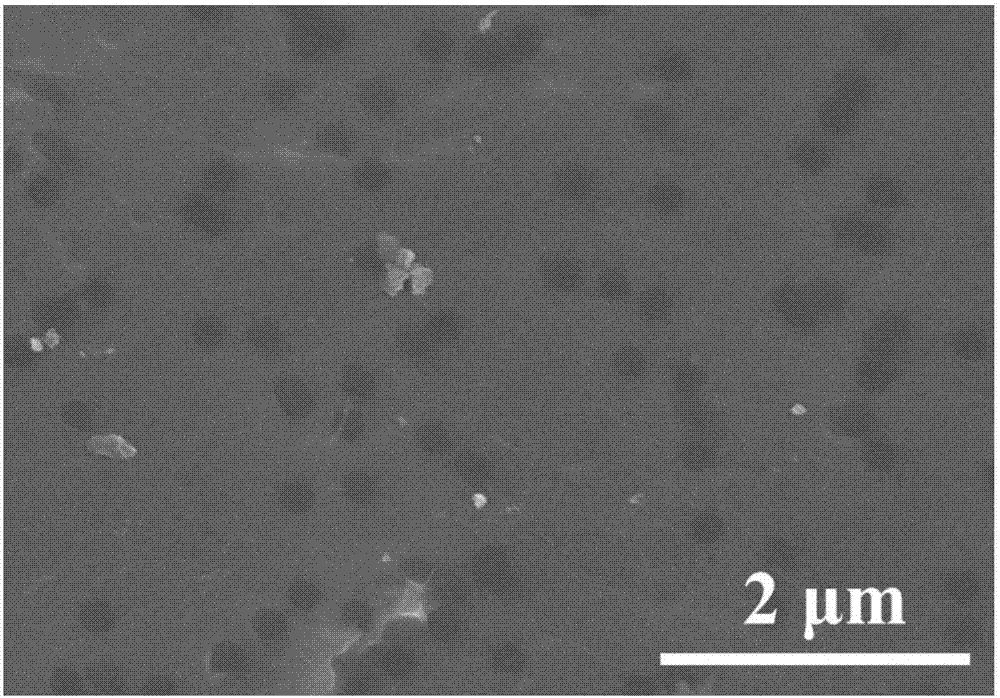

[0033] Take 5μl of the graphene oxide dispersion and add it to 400ml of deionized water, at a cross-flow pressure of 1bar, a cross-flow flow rate of 0.35LPM, and an effective membrane area of 3.14cm 2 , PC membrane with a pore size of 200nm, cross-flow membrane forming method for 30min, and an ultra-thin graphene oxide separation membrane was prepared. Such as figure 1 with 2 As shown, the thickness of the GO separation membrane is 10 nm.

Embodiment 3

[0035] 1) Preparation of graphene oxide dispersion:

[0036] Disperse the graphene oxide powder prepared above in deionized water, ultrasonically disperse, and make a 0.4g / L graphene oxide dispersion;

[0037] 3) Preparation of graphene oxide separation membrane:

[0038] Take 500 μl of graphene oxide dispersion and add it to 400ml of deionized water. At cross-flow pressure of 1 bar, cross-flow flow rate of 0.35 LPM, effective membrane area of 3.14 cm 2 , PC membrane with a pore size of 200nm, and a cross-flow membrane forming method for 5 minutes to prepare an ultra-thin graphene oxide separation membrane.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com