Treatment system and method for wastewater generated by cleaning flue gas of waste incineration

A wastewater treatment system and flue gas cleaning technology, applied in gaseous discharge wastewater treatment, multi-stage water treatment, water/sewage treatment, etc., can solve the problems of non-biodegradability, pollutant degradation and decolorization, and technical difficulties And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

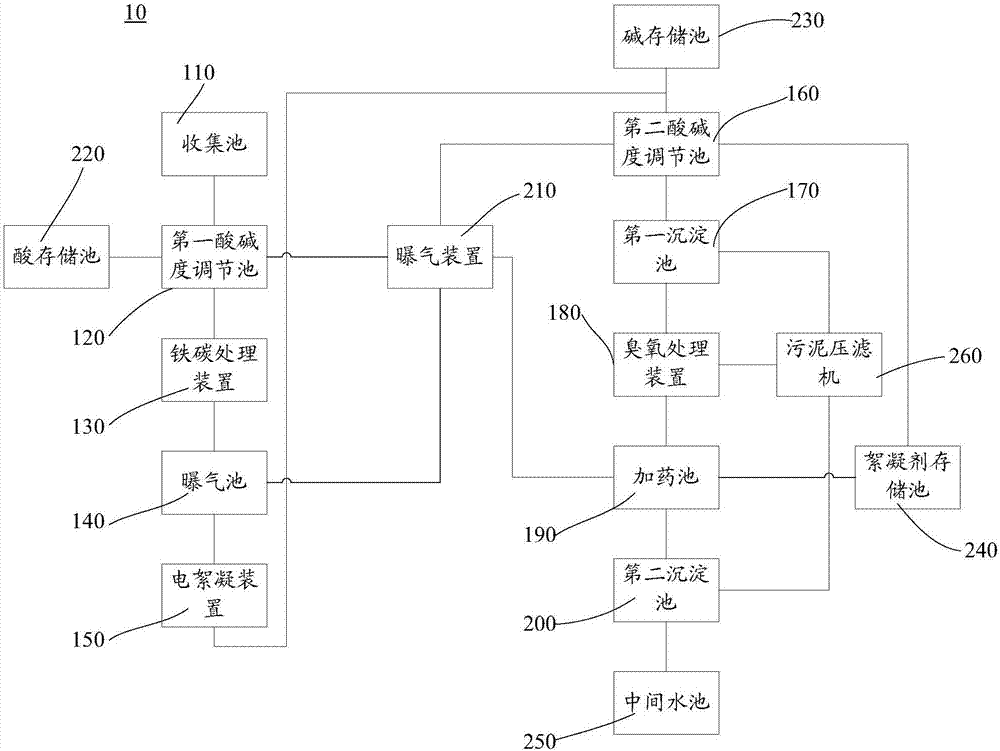

Image

Examples

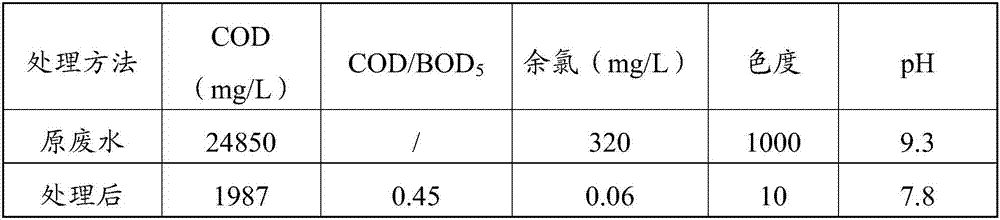

Embodiment 1

[0045] In this embodiment the effective volume of the pool is 2m 3 , collect enough 1.5m in the collection pool 3 After the wastewater, analyze the pH value and COD of the wastewater Cr and chroma etc.

[0046] (1) Iron carbon treatment

[0047] After collecting enough wastewater in the collection tank, discharge the wastewater into the first pH adjustment tank, turn on the aeration device, add sulfuric acid to the first pH adjustment tank to adjust the pH value of the wastewater to between 3 and 4, after the pH value adjustment is completed, put The waste water is discharged into the iron-carbon treatment device, and the time for the waste water to stay in the iron-carbon treatment device is 4 hours.

[0048] After the residence time of the wastewater in the iron-carbon treatment device is over, the wastewater is discharged to the aeration tank for aeration for 5 hours.

[0049] After the aeration is finished, the waste water is discharged into the electroflocculation dev...

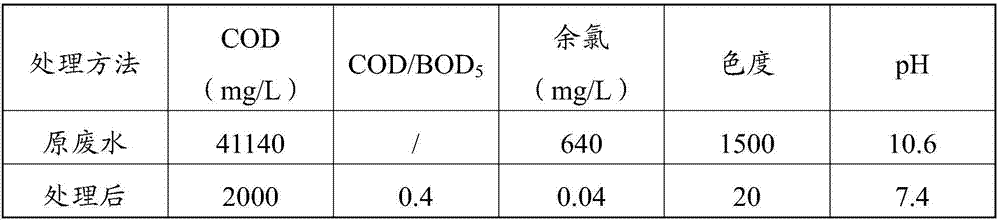

Embodiment 2

[0070] In this embodiment the effective volume of the collection pond is 4m 3 , enough to collect 3.5m in the collection pool 3 After the wastewater, analyze the pH value and COD of the wastewater Cr and chroma etc.

[0071] (1) Iron carbon treatment

[0072] After enough wastewater is collected in the collection tank, it is discharged into the first pH adjustment tank, the aeration device is turned on, and sulfuric acid is added to the first pH adjustment tank to adjust the pH of the wastewater to between 3 and 4.

[0073] After the pH adjustment is completed, the wastewater is discharged into the iron-carbon treatment device. The residence time of wastewater in the iron-carbon treatment device is 6 hours.

[0074] After the residence time of the wastewater in the iron-carbon treatment device is over, the wastewater is discharged into the aeration tank, and the aeration device is turned on for aeration for 3 hours.

[0075] After the aeration time is over, the wastewater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com