High-efficiency cleaning fluid for aluminum alloy mold

A technology of aluminum alloy and cleaning liquid, which is applied in the directions of detergent compounding agent, detergent composition, surface active detergent composition, etc., can solve the problem of affecting product quality mold service life, aluminum alloy surface erosion, low oil-dissolving efficiency, etc. problem, to achieve the effect of strong solubilization, good compatibility, and fast cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

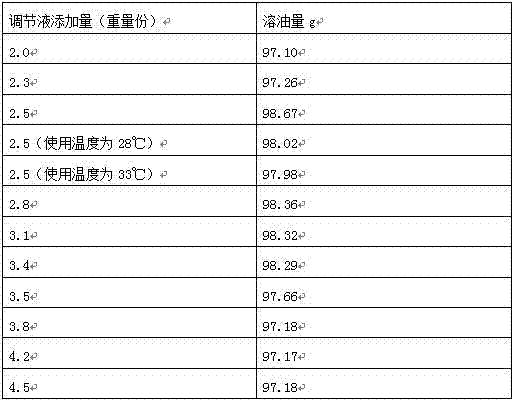

Image

Examples

Embodiment 1

[0025] A high-efficiency aluminum alloy mold cleaning solution, made of the following ingredients in parts by weight: propylene glycol laurate 3, glyceryl caprylate 5, polyethylene glycol 4, sodium tripolyphosphate 1.2, lauryl polyoxyethylene ether 1.3 , Regulating liquid 2.5, water 90;

[0026] The preparation method of the regulating solution is:

[0027] (1) Mix cactus, monstera leaves, grape seeds, and arrowroot leaves, and crush them to a particle size of 90 mesh to obtain a mixed crushed product, add water twice the weight of the mixed crushed product, heat and cook for 40 minutes, and after natural cooling, inoculate Aspergillus oryzae in test tubes, packed into a wooden box, cultured in a culture room at 32°C for 12 hours, the culture was obtained and sterilized;

[0028] (2) Add water to the above culture, water: culture weight ratio = 1: 2, under the condition of 50°C, stir at 850r / min for 30min, then add attapulgite powder with 2.5% of culture quality and culture q...

Embodiment 2

[0044] A high-efficiency aluminum alloy mold cleaning solution, which is made of the following ingredients in parts by weight: propylene glycol laurate 5, glyceryl caprylate 8, polyethylene glycol 6, sodium tripolyphosphate 1.5, lauryl polyoxyethylene ether 1.8 , adjusting liquid 3.4, water 100;

[0045] The preparation method of the regulating solution is:

[0046] (1) Mix cactus, monstera leaves, grape seeds, and arrowroot leaves, and crush them to a particle size of 90 mesh to obtain a mixed crushed product, add water twice the weight of the mixed crushed product, heat and cook for 40 minutes, and after natural cooling, inoculate Aspergillus oryzae in test tubes, packed into a wooden box, cultured in a culture room at 32°C for 12 hours, the culture was obtained and sterilized;

[0047] (2) Add water to the above culture, water: culture weight ratio = 1: 2, under the condition of 50°C, stir at 850r / min for 30min, then add attapulgite powder with 2.5% of culture quality and ...

Embodiment 3

[0063] A high-efficiency aluminum alloy mold cleaning solution, made of the following components by weight: propylene glycol laurate 4, glyceryl caprylate 6, polyethylene glycol 5, sodium tripolyphosphate 1.3, lauryl polyoxyethylene ether 1.5 , Regulating liquid 2.8, water 95;

[0064] The preparation method of the regulating solution is:

[0065] (1) Mix cactus, monstera leaves, grape seeds, and arrowroot leaves, and crush them to a particle size of 90 mesh to obtain a mixed crushed product, add water twice the weight of the mixed crushed product, heat and cook for 40 minutes, and after natural cooling, inoculate Aspergillus oryzae in test tubes, packed into a wooden box, cultured in a culture room at 32°C for 12 hours, the culture was obtained and sterilized;

[0066] (2) Add water to the above culture, water: culture weight ratio = 1: 2, under the condition of 50°C, stir at 850r / min for 30min, then add attapulgite powder with 2.5% of culture quality and culture quality 1....

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com