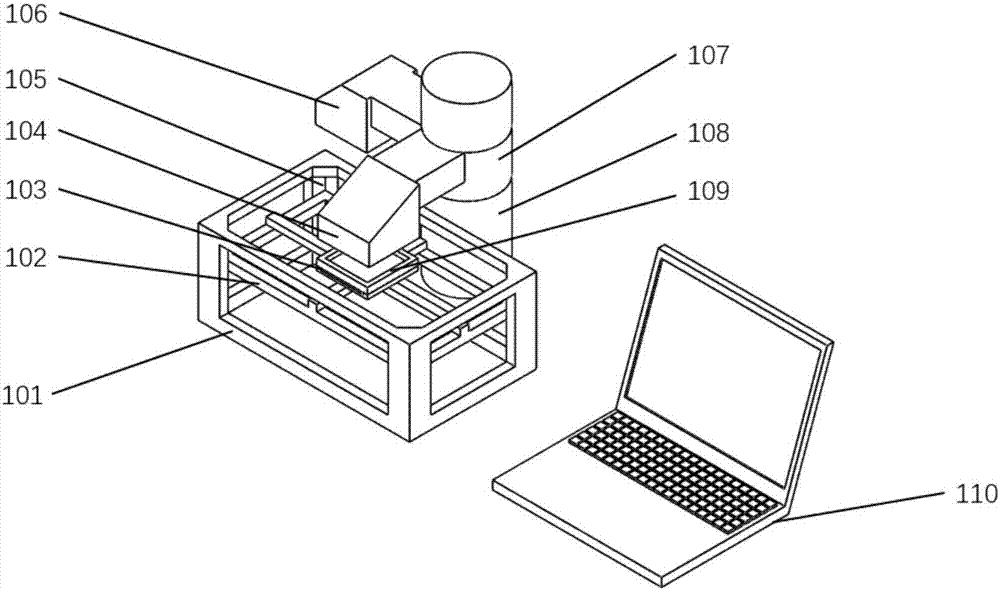

Method and device for preparing in-vitro three-dimensional tissue model

A technology for preparing devices and tissues, applied in the field of preparation of in vitro three-dimensional tissue models, can solve problems such as difficulty in manipulating the printing speed of cells, and achieve the effects of contributing to accuracy and rapid prototyping, strong applicability, and high survival rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

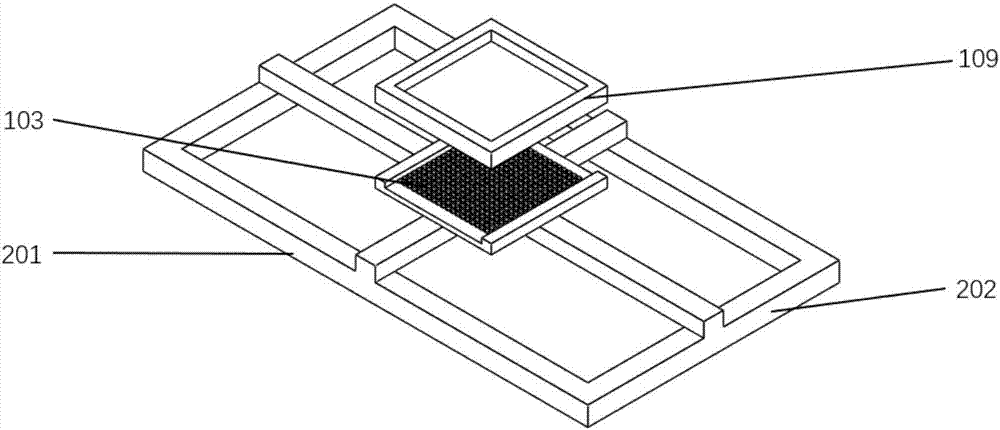

preparation example Construction

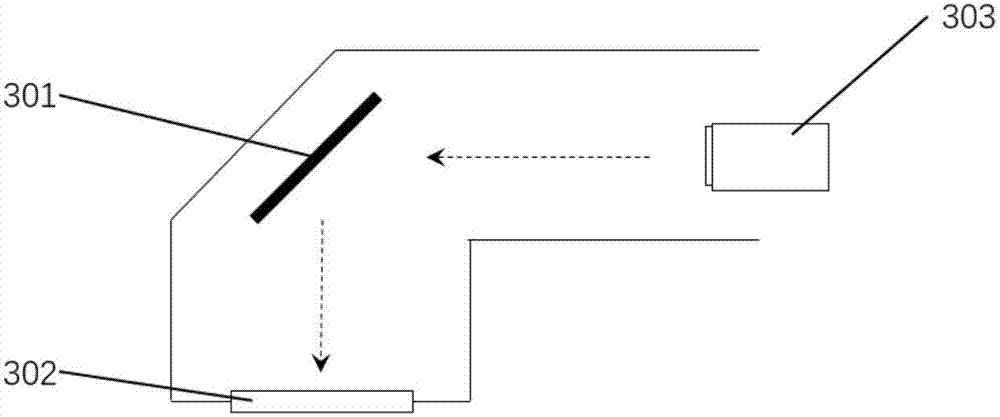

[0043] refer to Figure 4 to Figure 7 , in another embodiment, a method for preparing an in vitro three-dimensional tissue model, comprising the following steps:

[0044] (1) Using computer-aided design software to design a three-dimensional tissue model in vitro, layering the designed tissue model one by one, obtaining each layer of tissue after layering, and generating tissue pattern data of each layer. The thickness of each layer can be selected in the range of 100μm-1mm according to the needs, and the different thickness of each layer can be realized by pouring different doses of the compound solution.

[0045] (2) Mix the cells, growth factors and collagen solution evenly to obtain a mixed solution, then inject photocurable hydrogel into the mixed solution, and then add a photoinitiator to obtain a photocurable composite solution mixed with cells. According to the needs of tissue construction, different cells can be used in different layers of the tissue, and the growth ...

Embodiment 1

[0050] The preparation of the three-dimensional liver lobular tissue model in vitro, the specific steps are as follows:

[0051] (1) According to the characteristics of the hepatic lobular tissue structure, a three-dimensional hepatic lobular tissue model in vitro was designed by using computer-aided design software, and the designed tissue model was layered one by one. After layering, each layer of tissue was obtained, and the tissue pattern data of each layer was generated. The thickness of each layer is 100 μm.

[0052] (2) Mix the cells, growth factors and collagen solution evenly to obtain a mixed solution, then inject photocurable hydrogel into the mixed solution, and then add a photoinitiator to obtain a photocurable composite solution mixed with cells. Wherein the cells are human liver cells (702), endothelial cells and mesenchymal cells (701), the collagen in the collagen solution is type I collagen, the mixing density of the cells in the mixed solution is 1×〖10〗7 cel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com