Epoxy grouting glue for bonding sound barrier stand column and preparing method and construction technology of epoxy grouting glue

An epoxy grouting and sound barrier technology, applied in construction, noise absorption devices, etc., can solve the problems of low adhesive force, high cost of use, brittle cracking, etc., and achieve the effect of strong adhesive force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

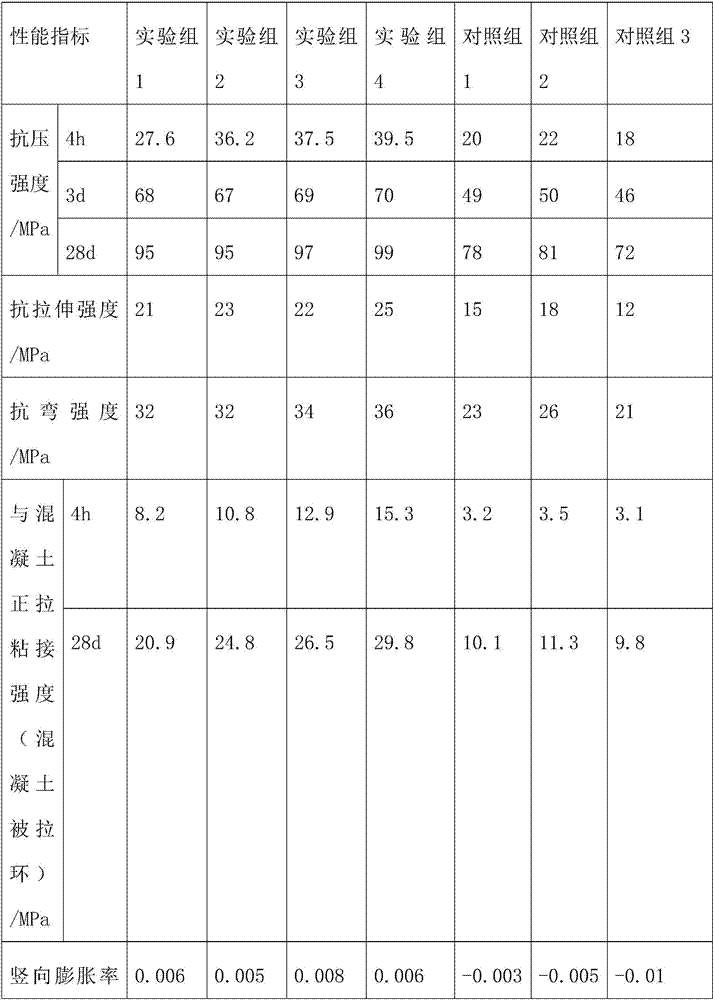

Embodiment 1

[0047] Mix epoxy resin, polyurethane, dibutyl phthalate, m-cresol and react at room temperature for 3 hours to obtain the first mixture; mix polyamine, salicylic acid and polyethylene glycol After reacting for 3 hours, the second mixture was obtained; after mixing the first mixture and the second mixture, adding quartz sand and PO42.5 cement, mixing and stirring evenly to obtain epoxy grouting glue for bonding sound barrier columns.

[0048] Among them, by weight, 5 parts of epoxy resin, 1 part of polyurethane, 0.5 part of dibutyl phthalate, 1 part of m-cresol, 2 parts of polyamine, 0.2 part of salicylic acid, 0.5 part of polyethylene glycol , 70 parts of quartz sand, 10 parts of PO42.5 cement.

Embodiment 2

[0050] Mix epoxy resin, polyurethane, dibutyl phthalate, and m-cresol and react at room temperature for 10 hours to obtain the first mixture; mix polyamine, salicylic acid, and polyethylene glycol After reacting for 10 hours, the second mixture was obtained; after mixing the first mixture and the second mixture, adding quartz sand and PO42.5 cement, mixing and stirring evenly to obtain epoxy grouting glue for bonding sound barrier columns.

[0051] Among them, by weight, 10 parts of epoxy resin, 5 parts of polyurethane, 1 part of dibutyl phthalate, 3 parts of m-cresol, 6 parts of polyamine, 0.8 part of salicylic acid, and 1 part of polyethylene glycol , 90 parts of quartz sand, 30 parts of PO42.5 cement.

Embodiment 3

[0053] Mix epoxy resin, polyurethane, dibutyl phthalate, m-cresol and react at room temperature for 5 hours to obtain the first mixture; mix polyamine, salicylic acid and polyethylene glycol After reacting for 5 hours, the second mixture was obtained; after mixing the first mixture and the second mixture, adding quartz sand and PO42.5 cement, mixing and stirring evenly to prepare epoxy grouting glue for bonding the sound barrier column.

[0054] Among them, by weight, 7 parts of epoxy resin, 2 parts of polyurethane, 0.6 part of dibutyl phthalate, 2 parts of m-cresol, 3 parts of polyamine, 0.4 part of salicylic acid, 0.6 part of polyethylene glycol , 75 parts of quartz sand, 15 parts of PO42.5 cement.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com