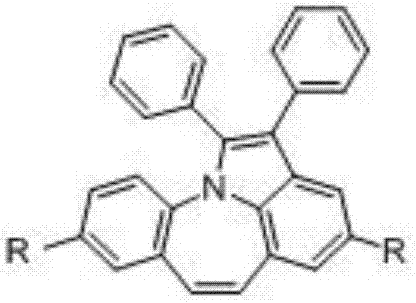

Organic light-emitting material and preparation method and application thereof

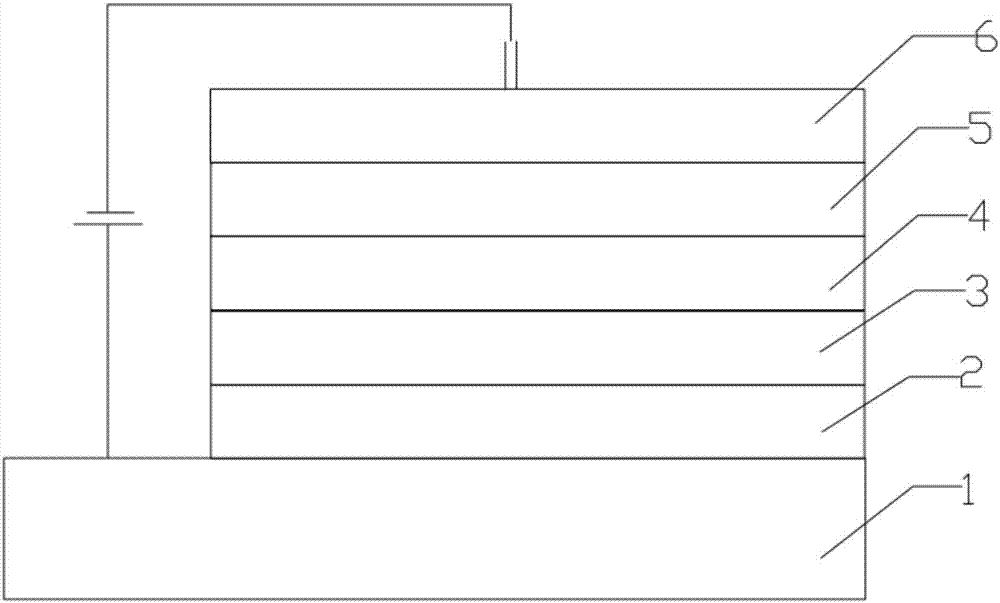

An electroluminescent material and electroluminescent technology, applied in the fields of luminescent materials, organic chemistry, chemical instruments and methods, etc., can solve the problems of low device life and efficiency, and achieve improved device life, good device performance, and good film stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] The preparation of embodiment 1 intermediate I

[0050]

[0051] In a 1L three-necked flask, add raw material 1 (111g, 0.3mol) and DMF (450g), and at 25°C, add N-bromosuccinimide (117g, 0.66mol) in batches, 1.5h after completion, 25 ℃ for 1 hour, heat up to 60°C, heat for 3 hours, cool down to 25°C, slowly pour the reaction solution into 2L of deionized water, stir for 1 hour, filter with suction, rinse with 1.5L of deionized water, collect the filter cake, and filter Purified on silica gel column, eluted with dichloromethane:petroleum ether=1:1 (V / V), further recrystallized with xylene to obtain intermediate I, refined product 109g, yield 69%, identified by high-resolution mass spectrometry, molecular formula C 28 h 19 Br 2 N, theoretical value 528.9864, test value 528.9859.

Embodiment 2

[0052]The preparation of embodiment 2 intermediate II

[0053]

[0054] In a 1L three-necked flask, add intermediate 1 (105g, 0.2mol), o-dichlorobenzene (600g), 2,3-dichloro-5,6-dicyano-p-benzoquinone (91g, 0.4mol), and heat up To 160°C, keep warm for 8 hours, lower the temperature to 25°C, wash with 300g deionized water, separate the liquid, collect the organic phase, remove o-dichlorobenzene under reduced pressure, add 1.6L toluene to dissolve, and quickly pass through a 280g basic alumina column, Rinse with toluene and remove the solvent. The obtained crude product was purified by silica gel column, eluted with dichloromethane:petroleum ether=1:1 (V / V), and further recrystallized with xylene to obtain intermediate II, 62g of fine product, Yield 59%, structure identified by high-resolution mass spectrometry, molecular formula C 28 h 17 Br 2 N, theoretical value 526.9707, test value 526.9701.

Embodiment 3

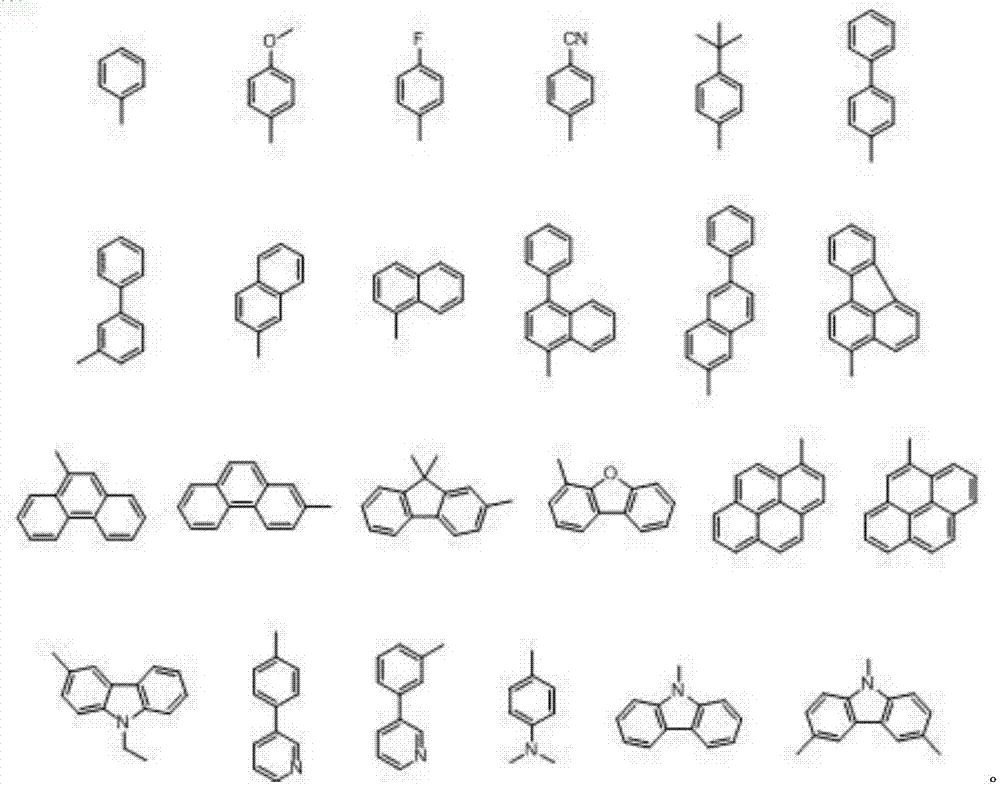

[0055] The preparation of embodiment 3 compound C01

[0056]

[0057] In a 100mL three-necked flask, add intermediate II (2.63g, 5mmol), phenylboronic acid (1.46g, 12mmol), potassium carbonate (2.07g, 15mmol), toluene (45mL) and deionized water (15g), N 2 Under protection, palladium acetate (0.022g, 0.1mmol) and phosphine ligand 2-bicyclohexylphosphine-2',6'-dimethoxy-1,1'-biphenyl (0.082g, 0.2mmol) were added, and the temperature was raised To reflux, react for 8 hours, stop the reaction, lower the temperature to 25°C, separate the liquid, wash the organic phase once with 30 mL deionized water, collect the organic phase, remove the solvent, and purify the obtained crude product by silica gel column chromatography, the eluent is n-hexane: Dichloromethane=2:1 (V / V), the crude product of target C01 was obtained, which was further sublimated and purified using a chemical vapor deposition system at a sublimation temperature of 335° C. to obtain 1.4 g of target C01 with a yield ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com