Halogen-free flame retardant and polymer material containing same

A flame retardant polymer and flame retardant technology, applied in the field of flame retardant polymer material preparation, can solve the problems of low environmental protection, poor thermal stability of bromoalkyl phosphonate, etc., and achieve the effect of overcoming degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

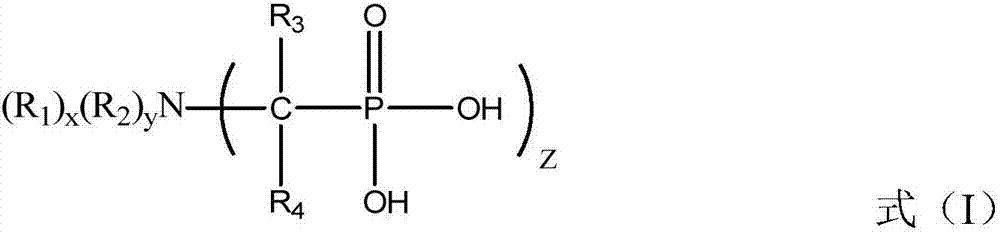

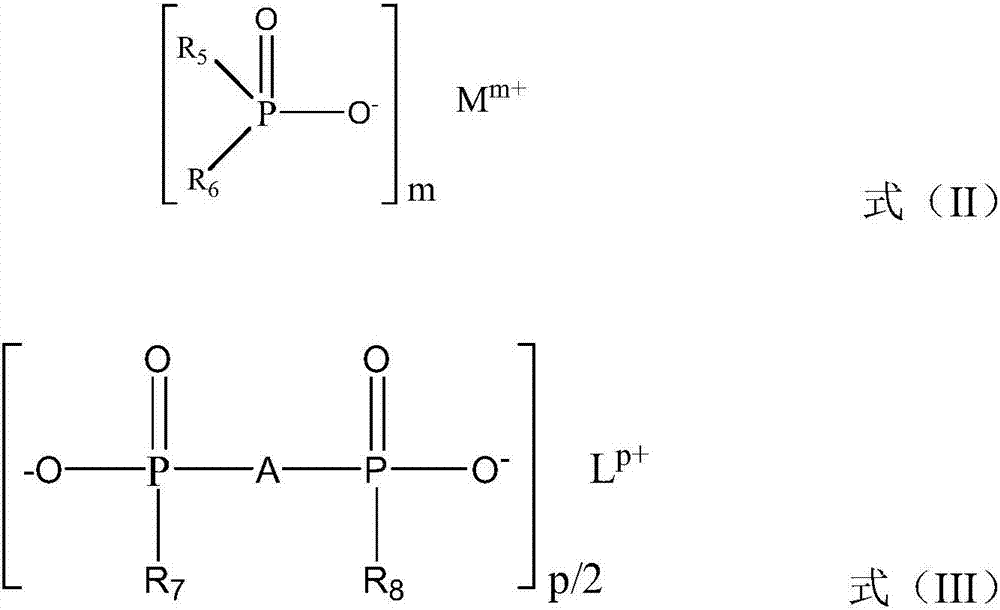

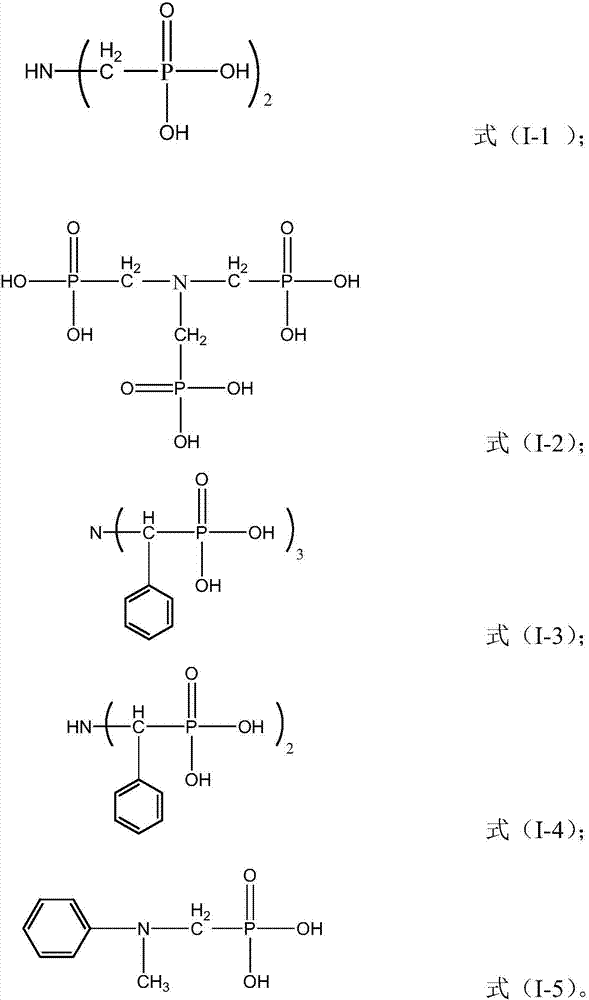

Method used

Image

Examples

Embodiment 1

[0101] Preparation of ATMP-Zn

[0102] Add 50wt% ATMP aqueous solution (173.00g, 0.29 moles) in a 500mL beaker, add dropwise 25wt% NaOH aqueous solution at room temperature, adjust pH to 6~7, consume altogether 231.32 grams (1.45 moles of NaOH) of NaOH aqueous solution, equivalent to To neutralize 5 acids in ATMP, leaving 1 acid. At room temperature, under stirring at a stirring speed of 300 to 400 rpm, it was added dropwise to 1000mL containing 30wt% ZnSO 4 ·7H 2 O (207.50g, 0.72mol) aqueous solution was added dropwise in a beaker within 1.5h, and stirred at room temperature for 0.5h. Suction filtration, water washing and drying were then carried out successively to obtain a white powdery solid, 120.84 g in total, with a yield of 91.50%, which was recorded as ATMP-Zn.

Embodiment 2

[0104] Preparation of ATMP-Zn-Ca Mixed Salt

[0105] Add 50wt% ATMP aqueous solution (19.38g, 0.0324 mol) in a 200mL beaker, add dropwise 10wt% NaOH aqueous solution at room temperature, adjust pH to 7, consume 66.4 grams (0.166 mol) NaOH aqueous solution altogether, be equivalent to neutralizing 5.12 acids in ATMP. At room temperature, under stirring at a stirring speed of 300 to 400 rpm, add it dropwise until CaCl is dissolved. 2 (1.86g, 0.0168 mol) and ZnCl 2 (9.09g, 0.0668 mole) (wherein Zn / Ca molar ratio = 4 / 1), the dropwise addition was completed within 40min, and stirred at room temperature for 0.5h. Suction filtration, water washing and drying were then carried out successively to obtain a white powdery solid, 13.17 g in total, with a yield of 90.1%, which was recorded as ATMP-Zn-Ca.

Embodiment 3

[0107] Mix polyamide PA66-B, DePAl-1, ATMP-Zn and compound antioxidant according to the weight ratio of 79.6:15:5:0.4 in an internal mixer with a rotating speed of 50 rpm and set the temperature at 280 ℃, after 5 minutes, take it out to cool and dry. Then fill it into a mold, preheat it in a flat vulcanizing machine at 280°C for 10 minutes, hold the pressure at 10MPa for 5 minutes, and then cold press it. The sample is off-white, and after it cools down, cut the sample and test it. The flame retardancy grades of the 1.6mm sample and the 0.8mm are both V-0.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com