Environment-friendly sheet material and preparation method thereof

An environmentally friendly, plate technology, applied in coating and other directions, can solve the problems of ecological environment pollution, non-functional plate, easy to cause cancer, etc., and achieve the effects of long service life, pleasant aroma and strong oxidation resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1 The preparation of an environment-friendly board comprises the following steps:

[0027] 40 parts of modified sweet potato powder solution, 125 parts of corn straw powder, 30 parts of wheat straw, 23 parts of mint powder, 8 parts of pot bottom ash, 350 parts of sophora japonicus powder, 15 parts of polylactic acid resin sepiolite powder, 22 parts of wollastonite , 5 parts of mica powder, 20 parts of melamine resin, 3 parts of titanium dioxide, 12 parts of modifier, 150 parts of hot water at 50-60°C.

[0028] Described modifying agent is stearyl alcohol;

[0029] The preparation method of the modified sweet potato powder solution: slowly add the sweet potato powder into the waste water, and mix and stir under the condition of sealing, heating and pressurizing; the pressure is 0.4MPa; the mixing and stirring time is 20min; the adding The temperature is 40°C; after mixing and stirring, add sophora japonicus powder and modifier to the treated solution; stir fo...

Embodiment 2

[0042] Embodiment 2 The preparation of an environment-friendly board comprises the following steps:

[0043] 45 parts of modified sweet potato powder solution, 130 parts of corn straw powder, 40 parts of wheat straw, 26 parts of mint powder, 10 parts of pot bottom ash, 36 parts of sophora japonicus powder, 18 parts of polylactic acid resin sepiolite powder, 25 parts of wollastonite , 6 parts of mica powder, 25 parts of melamine resin, 4 parts of titanium dioxide, 14 parts of modifier, 180 parts of hot water at 50-60°C.

[0044] Described modifying agent is stearyl alcohol;

[0045] The preparation method of the modified sweet potato powder solution: slowly add the sweet potato powder into the waste water, and mix and stir under the condition of sealing, heating and pressurizing; the pressure is 0.5MPa; the mixing and stirring time is 20min; the adding The temperature is 45°C; after mixing and stirring, add sophora japonicus powder and modifier to the treated solution; stir fo...

Embodiment 3

[0058] Embodiment 3 The preparation of an environment-friendly board comprises the following steps:

[0059] 50 parts of modified sweet potato powder solution, 135 parts of corn straw powder, 45 parts of wheat straw, 27 parts of mint powder, 13 parts of pot bottom ash, 40 parts of sophora japonicus powder, 21 parts of polylactic acid resin sepiolite powder, 26 parts of wollastonite , 7 parts of mica powder, 26 parts of melamine resin, 5 parts of titanium dioxide, 15 parts of modifier, 240 parts of hot water at 50-60°C.

[0060] Described modifying agent is stearyl alcohol;

[0061] The preparation method of the modified sweet potato powder solution: slowly add the sweet potato powder into the waste water, and mix and stir under the condition of sealing, heating and pressurizing; the pressure is 0.7MPa; the mixing and stirring time is 30min; the adding The temperature is 50°C; after mixing and stirring, add sophora japonicus powder and modifier to the treated solution; stir fo...

PUM

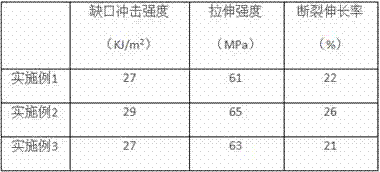

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Notched impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com