Stainless steel stain-resistant nano-coating and preparation method thereof

A nano-coating, anti-fouling technology, applied in coatings, antifouling/underwater coatings, paints containing biocides, etc., can solve problems such as weak adhesion, insufficiently dense coatings, and coating failures. Achieve the effect of improving hardness and scratch resistance, strong aesthetics, and dense coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

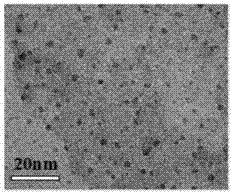

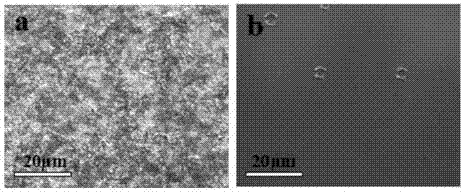

Image

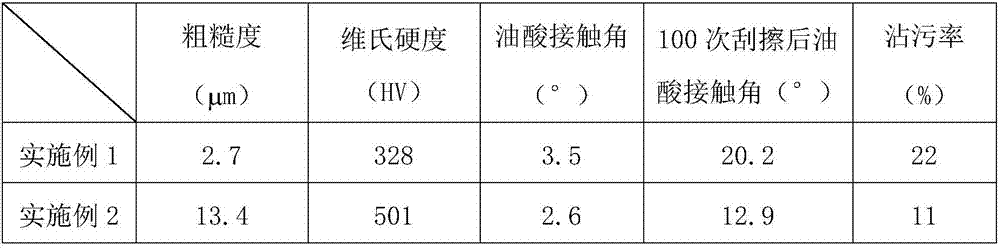

Examples

Embodiment 1

[0036] A method for preparing a stainless steel stain-resistant nano-coating, comprising the following steps:

[0037] S1: Take 700ml of distilled water, add 100ml of 3% titanium dioxide nano-sol, 100ml of 2% silica nano-sol and 100ml of 1% alumina nano-sol to the distilled water while stirring, and continue stirring for 30 minutes after adding the raw materials;

[0038] S2: adjust the pH value of the sol solution in S1 with hydrochloric acid until the sol solution is clear and transparent, and prepare a nano-sol coating solution;

[0039] S3: Clean the surface of the stainless steel plate with deionized water for 15 minutes, and then blow it with a hot air blower for 5 minutes;

[0040] S4: The surface of the stainless steel plate is treated by shot peening, and the nano-sol coating liquid is put into the shot chamber. The mass ratio of covering liquid and shot peening is 5:100, the diameter of projectile is 0.5mm, and the impact time is 10min;

[0041] S5: Under the prote...

Embodiment 2

[0045] A method for preparing a stainless steel stain-resistant nano-coating, comprising the following steps:

[0046] S1: Take 700ml of distilled water, add 100ml of 3% titanium dioxide nano-sol, 100ml of 2% silica nano-sol and 100ml of 1% alumina nano-sol to the distilled water while stirring, and continue stirring for 30 minutes after adding the raw materials;

[0047] S2: adjust the pH value of the sol solution in S1 with hydrochloric acid until the sol solution is clear and transparent, and prepare a nano-sol coating solution;

[0048] S3: Clean the surface of the stainless steel plate with deionized water for 15 minutes, and then blow it with a hot air blower for 5 minutes;

[0049]S4: The surface of the stainless steel plate is treated by shot peening, and the nano-sol coating liquid is put into the shot chamber. The mass ratio of covering liquid and shot peening is 0.1:100, the diameter of projectile is 3mm, and the impact time is 1min;

[0050] S5: Under the protect...

Embodiment 3

[0052] A method for preparing a stainless steel stain-resistant nano-coating, comprising the following steps:

[0053] S1: Take 685ml of distilled water, add 90ml of 3% titanium dioxide nano-sol, 85ml of 2% silica nano-sol and 90ml of 1% alumina nano-sol into the distilled water while stirring, continue stirring for 28 minutes after adding the raw materials;

[0054] S2: adjust the pH value of the sol solution in S1 with hydrochloric acid until the sol solution is clear and transparent, and prepare a nano-sol coating solution;

[0055] S3: Clean the surface of the stainless steel plate with deionized water for 12 minutes, and then blow it with a hot air blower for 3 minutes;

[0056] S4: The surface of the stainless steel plate is treated by sandblasting, and the method of drip feeding is used. While sandblasting, the nano-sol coating liquid is dripped to form a nano-coating on the surface of the stainless steel plate, and then blown to dry, in which the nano-sol coating The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com