Adhesive for shuttleless loom steel reed and preparation method thereof

A technology of mechanical reed and adhesive, applied in the direction of adhesive, adhesive type, conjugated diene adhesive, etc., can solve the problems of large influence of curing process temperature, low tensile and shear strength, insufficient toughness, etc., and improve the system Sedimentation and instability, improved molecular mobility, enhanced strength and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

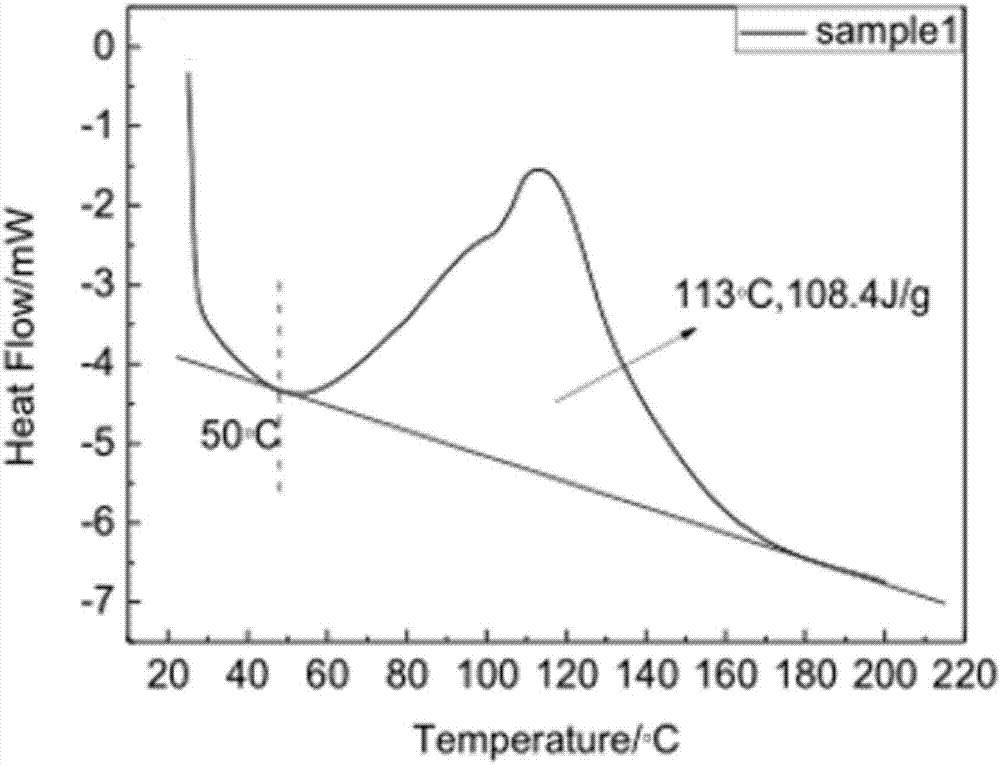

Image

Examples

preparation example Construction

[0040] A preparation method for an adhesive for a reed of a shuttleless loom, comprising the following steps:

[0041] 1) Add active diluent, filler, toughening agent and additive to epoxy resin and mix evenly, then add defoamer and mix evenly to obtain component A;

[0042] 2) Mix the filler, coupling agent, toughening agent and curing agent uniformly, then add additives and mix uniformly to obtain component B;

[0043] 3) Mix components A and B evenly at a mass ratio of 2:1 to obtain an adhesive for the reed of a shuttleless loom.

[0044] Specifically, in step 1), reactive diluents, fillers, toughening agents, and additives are added to the epoxy resin and stirred for 1.5-2 hours, and then defoamers are added and stirred for 0.5-1 hours to obtain component A at a speed of 800- 1200r / min.

[0045] In step 2), the filler, the coupling agent and the curing agent are mixed and stirred for 1-1.5 hours, and then the additives are added and stirred for 0.5-1 hours at a speed of ...

Embodiment 1

[0047] 1), in parts by weight, take 15 parts of allyl glycidyl ether, 40 parts of light calcium, 4 parts of nitrile rubber, nano-SiO 2 Add 2 parts of particles, 1 part of the mixture of polyamide and polyester, and 1 part of white carbon black to 40 parts of bisphenol A epoxy resin, stir for 2 hours at a speed of 800r / min, and then add 1 part of polyether defoamer , A component was obtained after stirring for 0.5h;

[0048] 2) Add 20 parts of microsilica powder, 15 parts of talc powder, 5 parts of light calcium, and 1 part of silane coupling agent into a liquid composed of 20 parts of modified diethylenetriamine and 35 parts of modified polyamide at a speed of 800r / min Stir for 1.5h, then add 3 parts of white carbon black, stir for 1h to obtain component B;

[0049] 3) Take the above components A and B respectively according to the weight ratio of 2:1, and mix them uniformly to obtain the adhesive for the reed of the shuttleless loom.

Embodiment 2

[0051] 1), in parts by weight, take 12 parts of n-butyl glycidyl ether, 30 parts of light calcium, 4 parts of nitrile rubber, nano-SiO 2 Add 4 parts of particles, 2 parts of a mixture of polyamide and polyester, and 1 part of white carbon black to 37 parts of bisphenol A epoxy resin, stir at a speed of 850r / min for 1.8h, and then add polyether defoamer 0.9 parts were stirred for 0.6h to obtain component A;

[0052] 2), add 30 parts of heavy calcium, 16 parts of talcum powder, 1 part of nitrile rubber, and 2 parts of silane coupling agent into the liquid composed of 15 parts of modified diethylenetriamine and 35 parts of modified polyamide at a speed of 850r / Stir at 1 min for 1.5 h, then add 2 parts of white carbon black, and stir for 0.5 h to obtain component B;

[0053] 3) Take the above components A and B respectively according to the weight ratio of 2:1, and mix them uniformly to obtain the adhesive for the reed of the shuttleless loom.

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap