Multi-principal-element alloy target material and preparation method thereof

A multi-principal alloy, alloy target technology, applied in metal material coating process, ion implantation plating, coating and other directions, to achieve the effect of uniform heating, uniform composition and structure, and short sintering time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

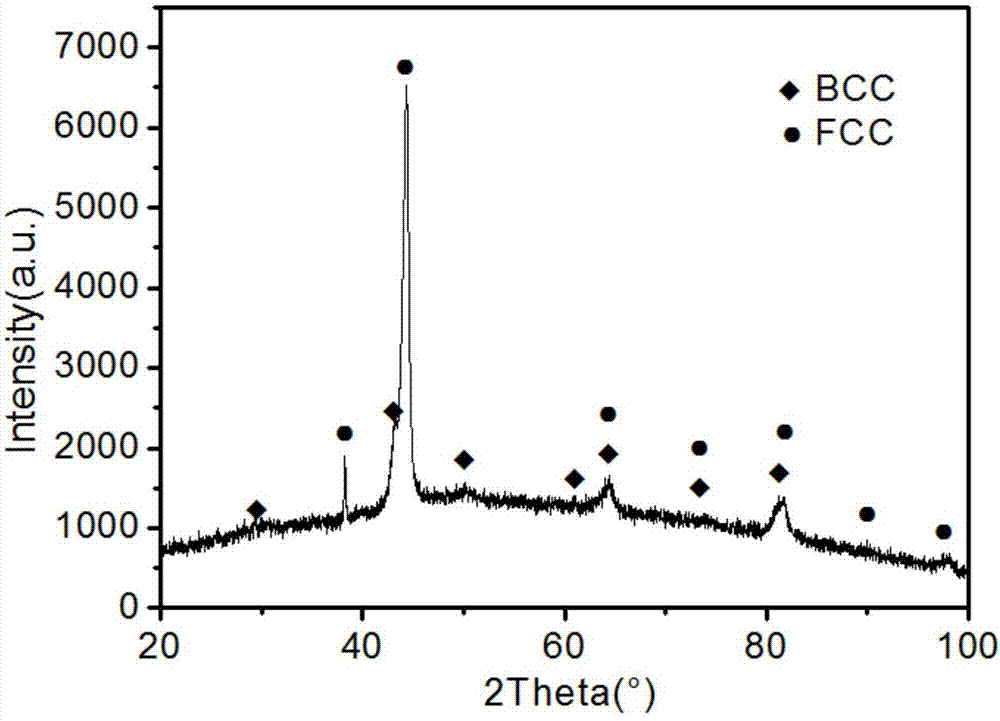

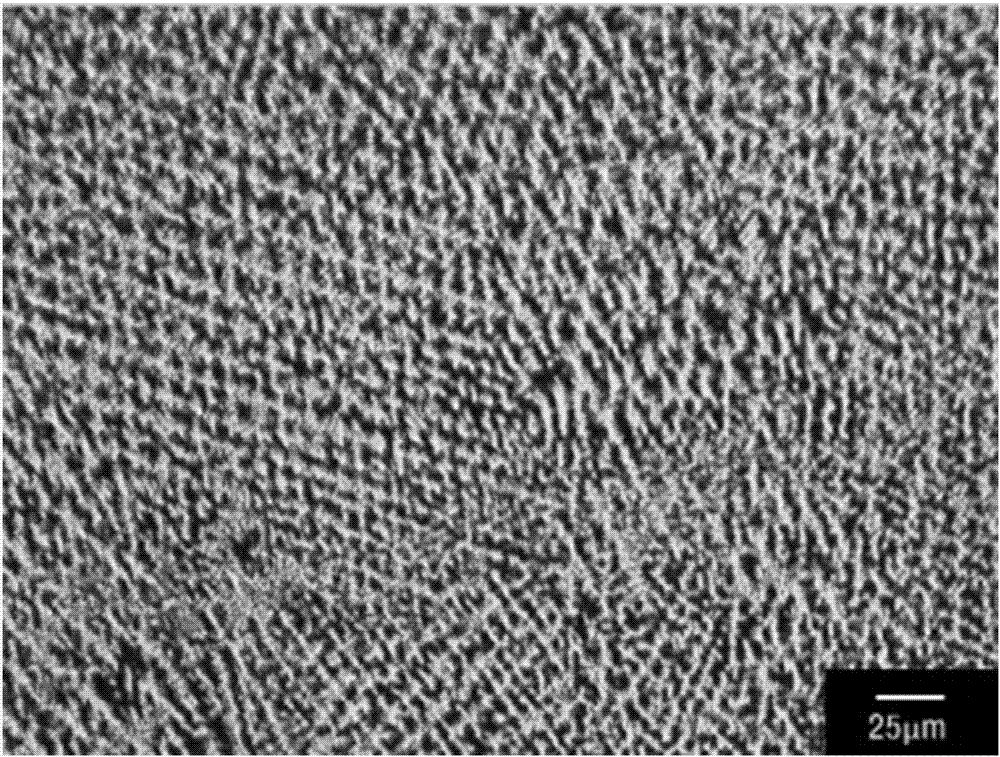

[0020] The invention provides a multi-principal alloy target, which is specifically an alloy target containing metal elements Al, Co, Cr, Ni, Mn and Mg, and its chemical composition is Al x CoCrNi y mn z Mg r , x=1; y=1; z=1; r=0.3.

[0021] The preparation method of the above-mentioned multi-principal alloy target comprises the following steps:

[0022] (1) According to the chemical composition AlCoCrNiMnMg 0.3 Weigh 0.40mol aluminum powder, 0.40mol cobalt powder, 0.40mol chromium powder, 0.40mol nickel powder and manganese powder and 0.12mol magnesium powder respectively, and set aside; the purity of each of the above metal powders is higher than 99.5%, and each metal powder The particle size is 200-500 mesh;

[0023] (2) Put the metal powder weighed in step (1) into a ball milling jar, add an appropriate amount of stainless steel balls, and then seal the ball milling jar with the metal powder in a nitrogen environment; then put the sealed ball milling jar Place on a p...

Embodiment 2

[0026] The invention provides a multi-principal alloy target, which is specifically an alloy target containing metal elements Al, Co, Cr, Ni, Mn and Mg, and its chemical composition is Al x CoCrNi y mn z Mg r , x=1; y=1; z=1; r=1.

[0027] The preparation method of the above-mentioned multi-principal alloy target comprises the following steps:

[0028] (1) Weigh 0.40mol aluminum powder, 0.40mol cobalt powder, 0.40mol chromium powder, 0.40mol nickel powder, 0.40mol manganese powder and 0.40mol magnesium powder according to the chemical composition AlCoCrNiMnMg, and set aside; Higher than 99.5%, the particle size of each metal powder is 200-500 mesh;

[0029] (2) Put the metal powder weighed in step (1) into a ball milling jar, add an appropriate amount of stainless steel balls, and then seal the ball milling jar with the metal powder in a nitrogen environment; then put the sealed ball milling jar Place on a planetary ball mill for mixing, the mixing speed is 200rpm, and th...

Embodiment 3

[0032] The invention provides a multi-principal alloy target, which is specifically an alloy target containing metal elements Al, Co, Cr, Ni, Mn and Mg, and its chemical composition is Al x CoCrNi y mn z Mg r , x=1; y=1; z=0.3; r=1.

[0033] The preparation method of the above-mentioned multi-principal alloy target comprises the following steps:

[0034] (1) According to the chemical composition AlCoCrNiMn 0.3 Mg takes by weighing 0.40mol aluminum powder, 0.40mol cobalt powder, 0.40mol chromium powder, 0.40mol nickel powder, 0.40mol magnesium powder and 0.12mol manganese powder respectively, for subsequent use; the purity of each of the above metal powders is higher than 99.5%. The particle size of each metal powder is 200-500 mesh;

[0035] (2) Put the metal powder weighed in step (1) into a ball milling jar, add an appropriate amount of stainless steel balls, and then seal the ball milling jar with the metal powder in a nitrogen environment; then put the sealed ball mil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com