A kind of preparation method and application of compressible graphene airgel and supercapacitor

A supercapacitor and aerogel technology, applied in the field of electrochemical energy, can solve problems such as poor compression performance and elastic performance, irreversible deformation structure collapse, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] 1 Experimental part

[0049] 1.1 Raw materials and reagents

[0050] Table 1 Main raw materials and reagents

[0051]

[0052]

[0053] 1.2 Experimental equipment

[0054] Table 2 main experimental equipment

[0055]

[0056] 1.3 Preparation method

[0057] 1.3.1 Purification of pyrrole

[0058] Take 10mL of pyrrole (yellow liquid) and use an oil bath for vacuum distillation (pay attention to the airtightness and light protection of the experimental operation). First, set the temperature to 40°C. Raise it to 65°C, at this time, a colorless liquid slowly flows out from the horn tube, which is the purified pyrrole (Py) monomer.

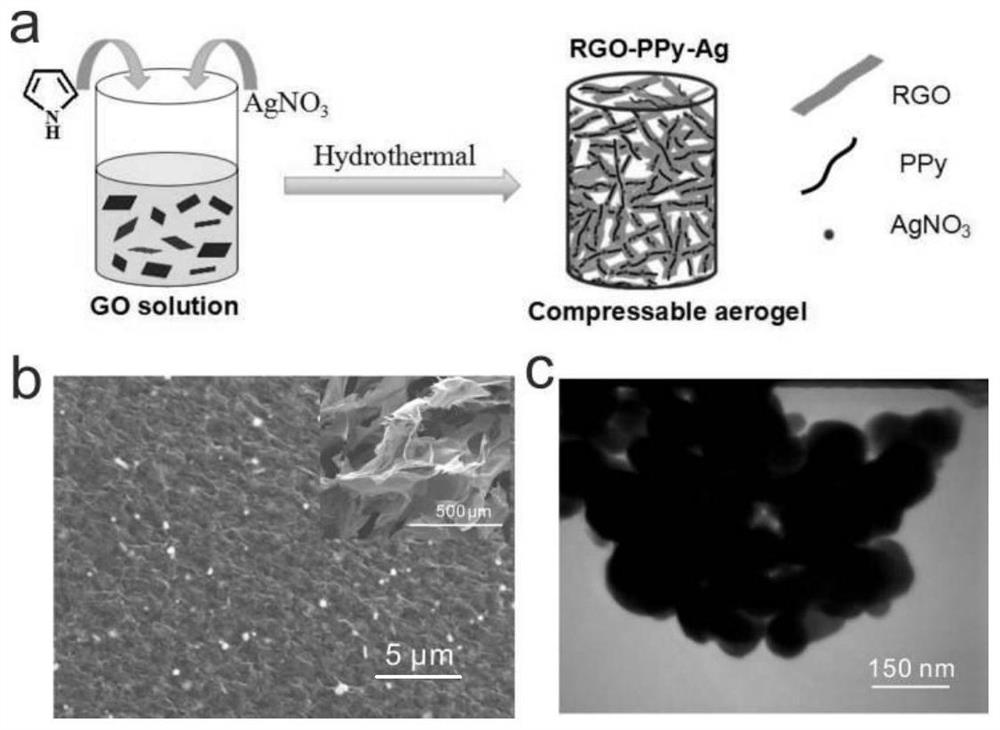

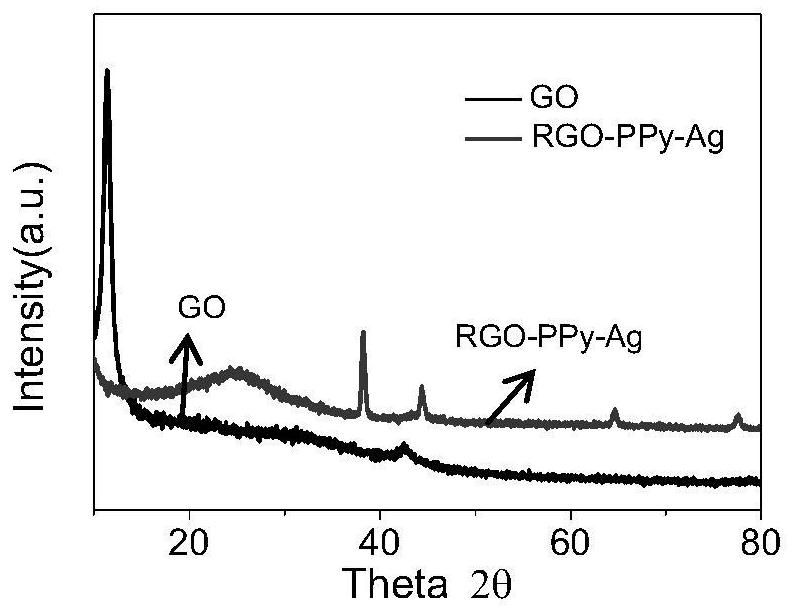

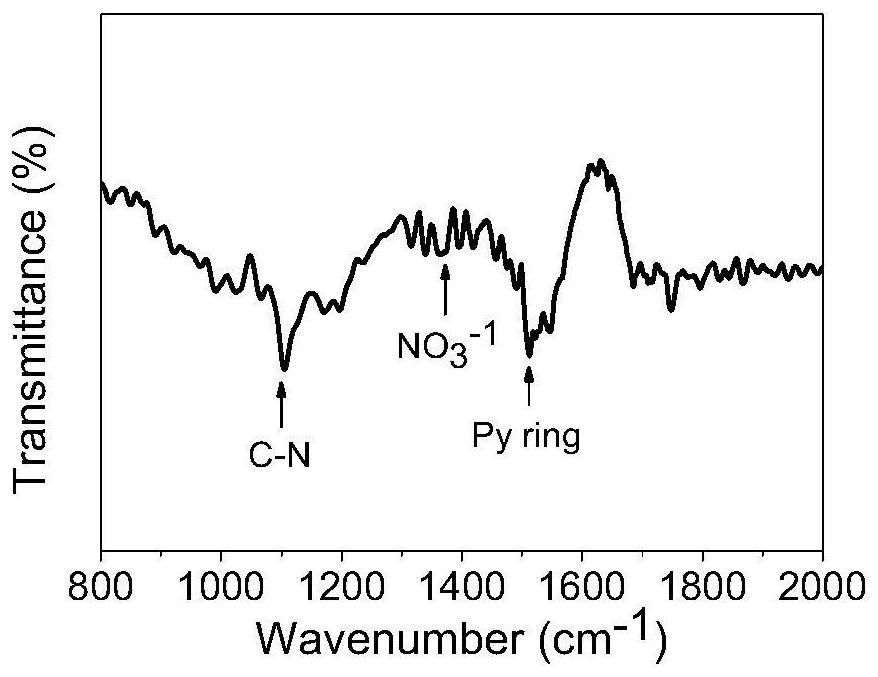

[0059] 1.3.2 Preparation of RGO-PPy-Ag airgel by one-step hydrothermal method

[0060] The specific preparation process of graphene oxide is as follows: In a 25mL small beaker, add 25mg of ultrasonically dispersed GO aqueous solution, 2.1-12.5mg of Py ethanol solution, AgNO 3 1-6.3mg aqueous solution, seal the beaker with plastic ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com