A kind of supercapacitor electrode material and preparation method thereof

A technology for supercapacitors and electrode materials, applied in the field of electrochemical materials, can solve the problems of complex preparation methods and limited improvement of electrode activity, and achieve the effects of simple preparation methods, changes in organizational structure and electrochemical properties, and improvement in specific capacitance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] A kind of preparation method of above-mentioned supercapacitor electrode material, comprises the following steps:

[0025] S1, performing surface etching treatment on the metal substrate;

[0026] S2, respectively configure the metal salt solutions of Mn, Co and Ru, and then mix and dissolve the metal salt solutions of Mn, Co and Ru in ethanol according to the molar ratio of Mn, Co and Ru, respectively, to obtain a composite metal salt solution;

[0027] S3, coating the composite metal salt solution on the surface of the metal substrate after surface etching treatment, drying and curing, and thermal oxidation treatment at 290-310° C. for 30-50 minutes.

[0028] Further, in a preferred embodiment of the present invention, the surface etching treatment step of the metal substrate includes: placing the metal substrate in an oxalic acid solution with a mass fraction of 8-15%, treating for 1-4 hours, cleaning and drying. After acid etching, the oxide film on the surface of ...

Embodiment 1

[0041] A kind of supercapacitor electrode material that the present embodiment provides, it is prepared according to the following steps:

[0042] (1) Put the titanium substrate in an oxalic acid solution with a mass fraction of 10%, heat it on an electric furnace until the solution boils for 3 hours, take it out, wash it, and dry it for later use.

[0043] (2) Prepare MnCl of 1mol / L concentration respectively 2 、CoCl 3 、RuCl 3 The solution, according to the mole percentage of Ru:Co:Mn is 4:3:3 prepare above-mentioned metal salt solution, dissolve it in ethanol and mix uniformly in ultrasonic, obtain composite metal oxide solution, wherein, composite metal oxide solution The total metal ion concentration in the medium is 0.5mol / L.

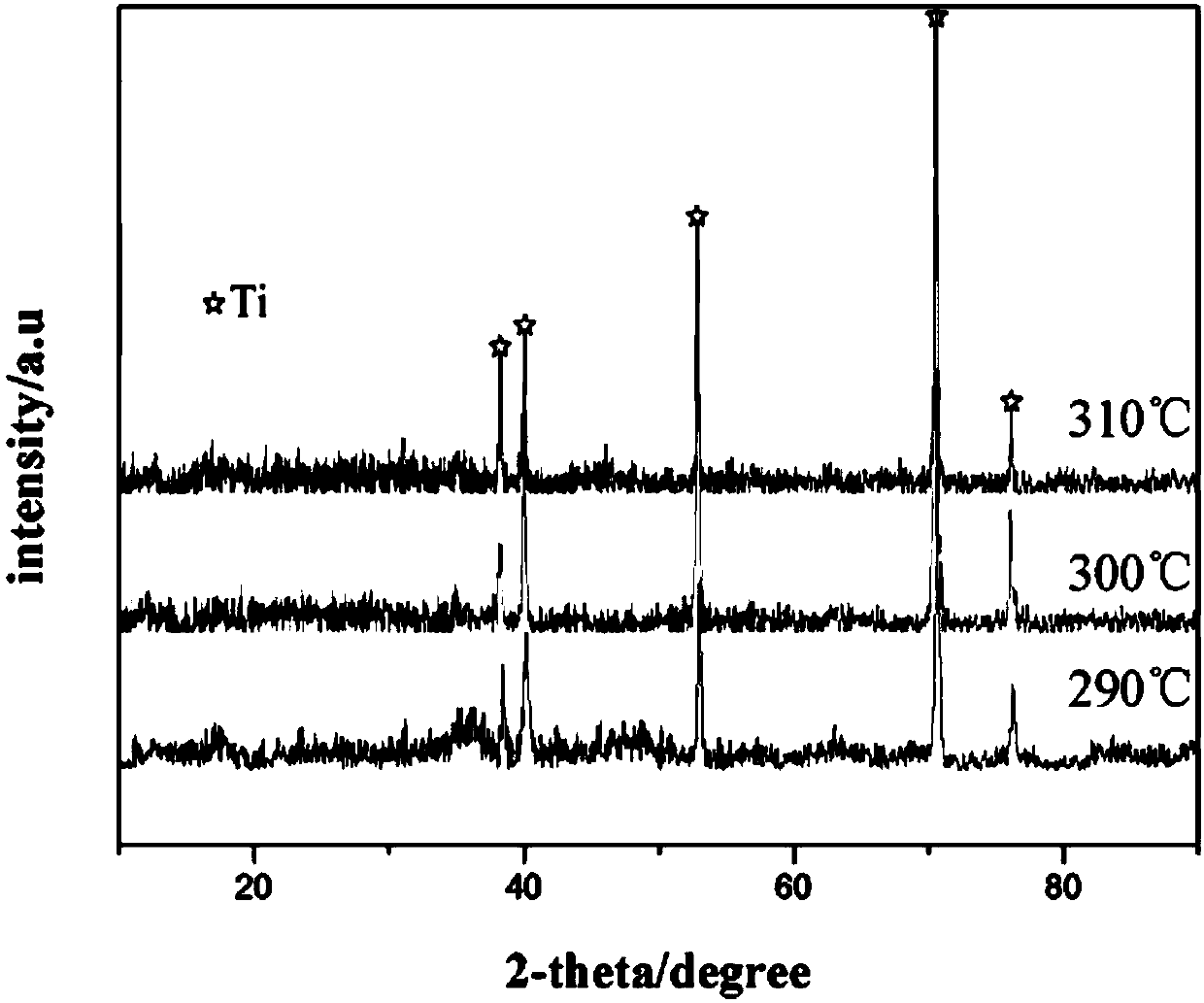

[0044] (3) Apply the prepared composite metal solution evenly on the titanium substrate, dry and solidify, anneal at 290°C, 300°C, and 310°C for 30 minutes, take it out, and cool.

[0045] Such as figure 1 Shown is the SEM image of the superca...

Embodiment 2

[0048] A kind of supercapacitor electrode material that the present embodiment provides, it is prepared according to the following steps:

[0049] (1) Put the titanium substrate in an oxalic acid solution with a mass fraction of 10%, heat it on an electric furnace until the solution boils for 3 hours, take it out, wash it, and dry it for later use.

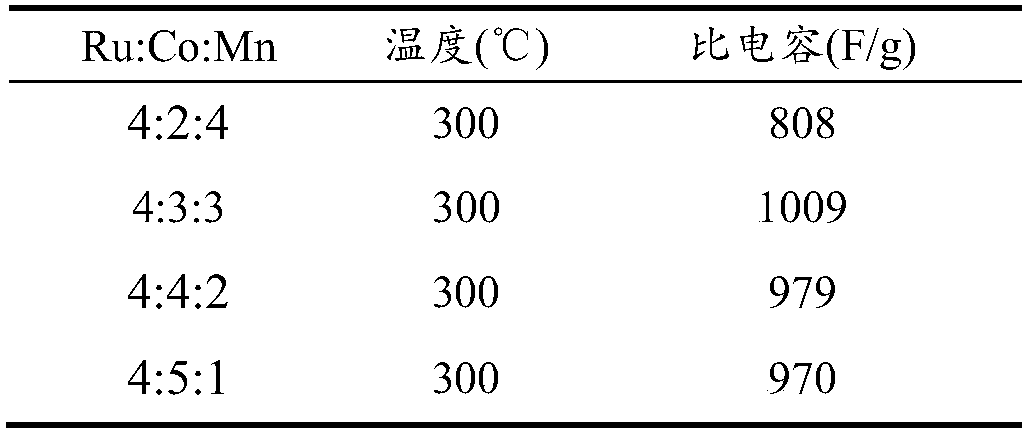

[0050] (2) Prepare MnCl of 1mol / L concentration respectively 2 、CoCl 3 、RuCl 3 According to the molar percentage of Ru:Co:Mn of 4:2:4, 4:3:3, 4:4:2, 4:5:1, prepare the above metal salt solution, dissolve it in ethanol and ultrasonically and mixed uniformly to obtain a composite metal oxide solution, wherein the total metal ion concentration in the composite metal oxide solution is 0.5 mol / L.

[0051] (3) Apply the prepared composite metal solution evenly on the titanium substrate, dry and solidify, anneal at 300°C for 30min, take it out, and cool it down.

[0052] As shown in Table 1, it is the specific capacitance value of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com