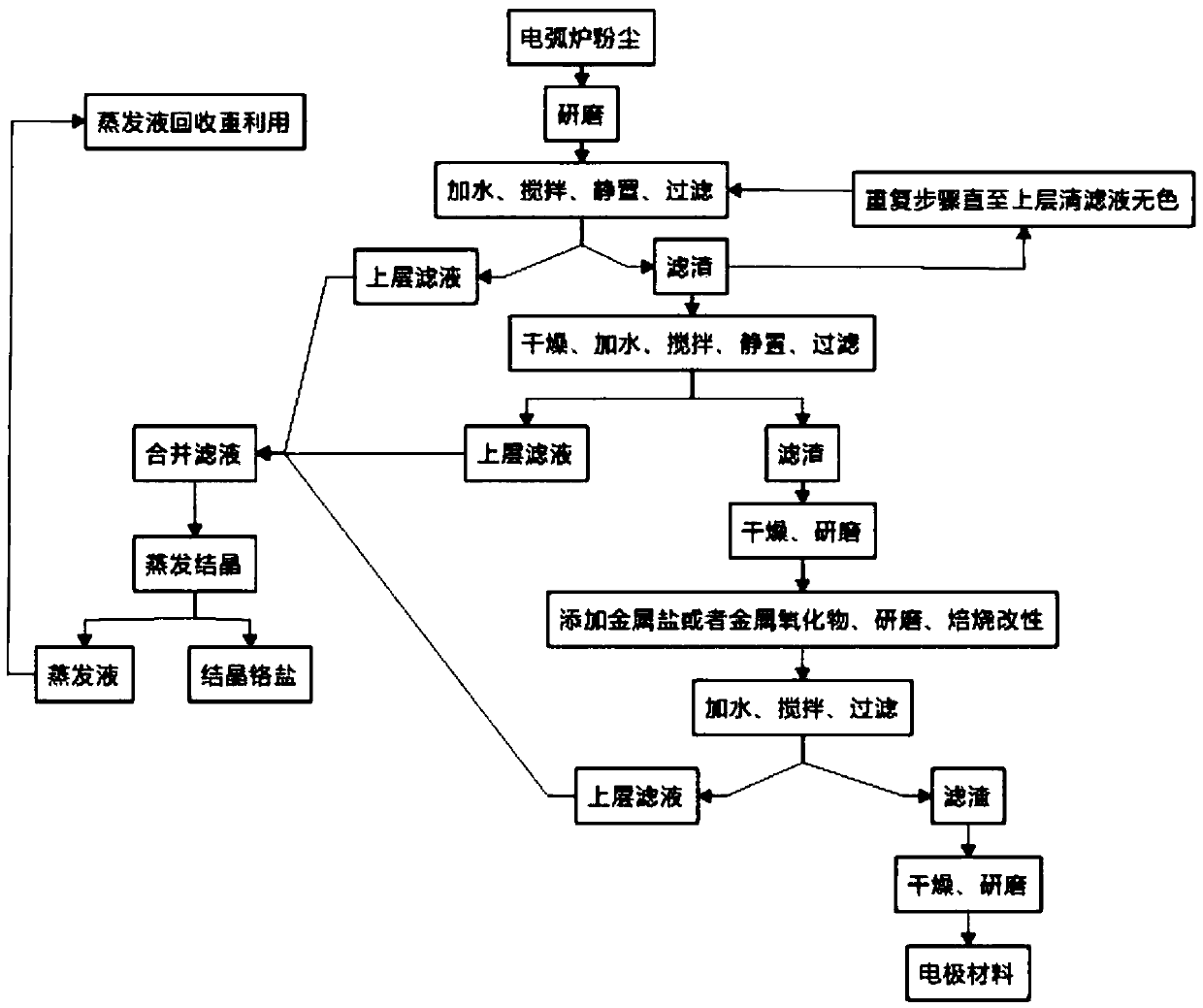

Method for Co-production of Chromium Salt and Electrode Material from Electric Arc Furnace Dust

A technology of electric arc furnace dust and electrode materials, applied in battery electrodes, chemical instruments and methods, circuits, etc., can solve the problems of limited use development, complex dust composition, and inability to achieve full use of dust, to eliminate secondary pollution, The effect of obvious modification effect and simple and feasible implementation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

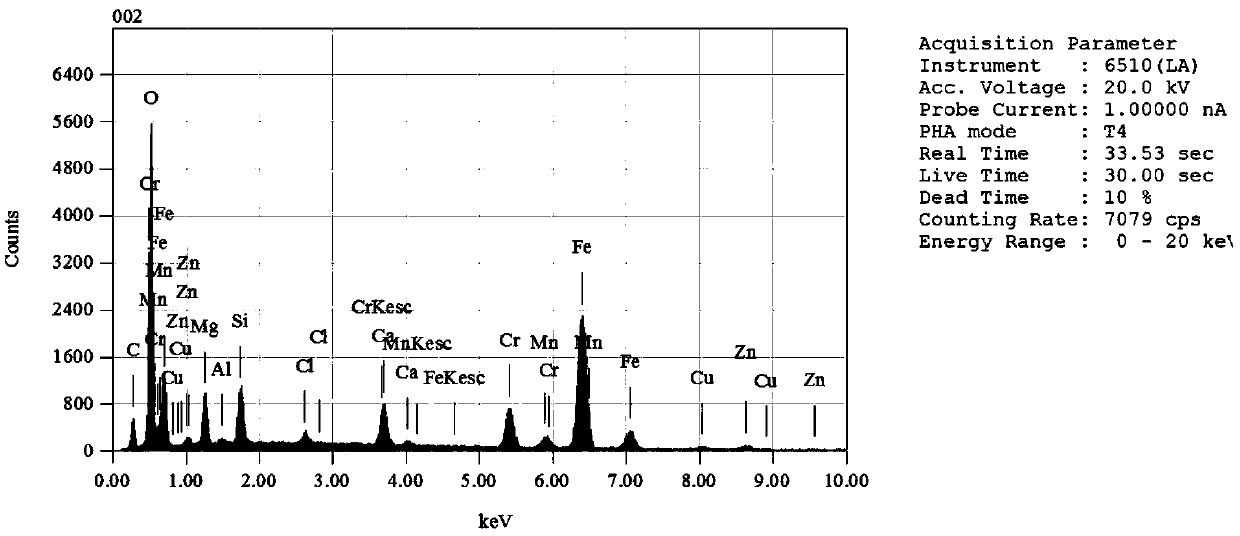

[0050] Take 20g of dust and grind it with a grinder for 4 hours; put the dust in a 1L beaker, add water and stir vigorously, put the supernatant after standing for 2 hours in another container, add fresh water to the dust, repeat the above Operate until the supernatant is colorless, filter, and save the filter cake and filtrate; place the filter cake in an oven and dry at room temperature; put the dried dust in fresh water again, add water and stir vigorously, let stand, and filter Pour the filtrate of the above filtrate into the above filtrate, and dry the filter cake again at room temperature; put all the above filtrates in an evaporator, set the temperature at 100°C, and evaporate the water to dryness, the obtained crystals are the product chromium salts, and the obtained crystals are chromium Potassium chromate and sodium chromate, the extraction rate of chromium is more than 80%, and the chromium salt is mainly potassium chromate and sodium chromate, with a purity of more ...

Embodiment 2

[0052] Take 20g of dust and grind it with a grinder for 4 hours; put the ground dust in a beaker, add water and stir vigorously and let it stand, pour out the upper layer filtrate and put it in another beaker, then add fresh water to the dust, repeat the above operation, Until the upper filtrate is colorless; filter, save the filter cake and filtrate, mix all the above filtrates, and dry the filter cake at 120°C; place the dried dust in fresh water again, add water and stir vigorously, then let it stand, and filter the filtrate Pour it into the above filtrate, and dry the filter cake at 120°C again; put all the above filtrate in an evaporator, set the temperature at 120°C, and evaporate the water in it, and the obtained crystal is a mixture of potassium chromate and sodium chromate, The purity is above 75%, and the extraction rate of chromium is above 78%. Put the above-mentioned dried filter cake in a grinder and grind for 2 hours, then add nickel oxide, wherein the molar rati...

Embodiment 3

[0054] Take 20g of dust and grind it with a grinder for 4 hours; put the dust in a 1L beaker, add water and stir vigorously, put the upper filtrate poured out after standing for 2 hours in another container, then add fresh water to the dust, repeat the above operation , until the upper filtrate is colorless, filter, save the filter cake and filtrate; dry the filter cake at room temperature; place the dried dust in fresh water again, add water and stir vigorously and let it stand, pour the filtered filtrate into the above filtrate, and Dry the filter cake at room temperature again; put all the above-mentioned filtrates in an evaporator, set the temperature at 50°C, and evaporate the water to dryness, the obtained crystals are potassium chromate and sodium chromate, the extraction rate of chromium is more than 80%, and the chromium salt is mainly It is potassium chromate and sodium chromate with a purity of more than 72%; the above-mentioned dried filter cake is placed in a grind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com