Antimony sulfide based negative electrode material with high reversible capacity and preparation and application thereof

An antimony sulfide-based, negative electrode material technology, applied in nanotechnology for materials and surface science, battery electrodes, electrochemical generators, etc., to achieve the effect of maintaining stability, uniform distribution, and improving cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Sb in this example 2 S 3 -The preparation method of Graphite composite material (being the antimony sulfide base negative electrode material with high reversible capacity), comprises the following steps:

[0044] Mix pure antimony sulfide and ordinary graphite powder, wherein the mass ratio of antimony sulfide powder and ordinary graphite powder is 4:1, add 2% absolute ethanol of the total mass of abrasive (pure antimony sulfide and ordinary graphite powder), use dielectric barrier Discharge plasma assisted high-energy ball milling, in which the mass ratio of balls to mixed powder (antimony sulfide powder and ordinary graphite powder) is 50:1, and the ball milling time is 3h; Sb 2 S 3 -Graphite composite material is antimony sulfide-based negative electrode material, and its powder size is less than 5 μm.

[0045] Wherein the specific steps of the dielectric barrier discharge plasma-assisted high-energy ball milling method are as follows:

[0046] (1) Load grinding ...

Embodiment 2

[0054] Sb in this example 2 S 3 -The preparation method of the Graphite-based composite material (that is, the antimony sulfide-based negative electrode material with high reversible capacity) is the same as in Example 1, except that the mass ratio of antimony sulfide powder and ordinary graphite powder is 1:1.

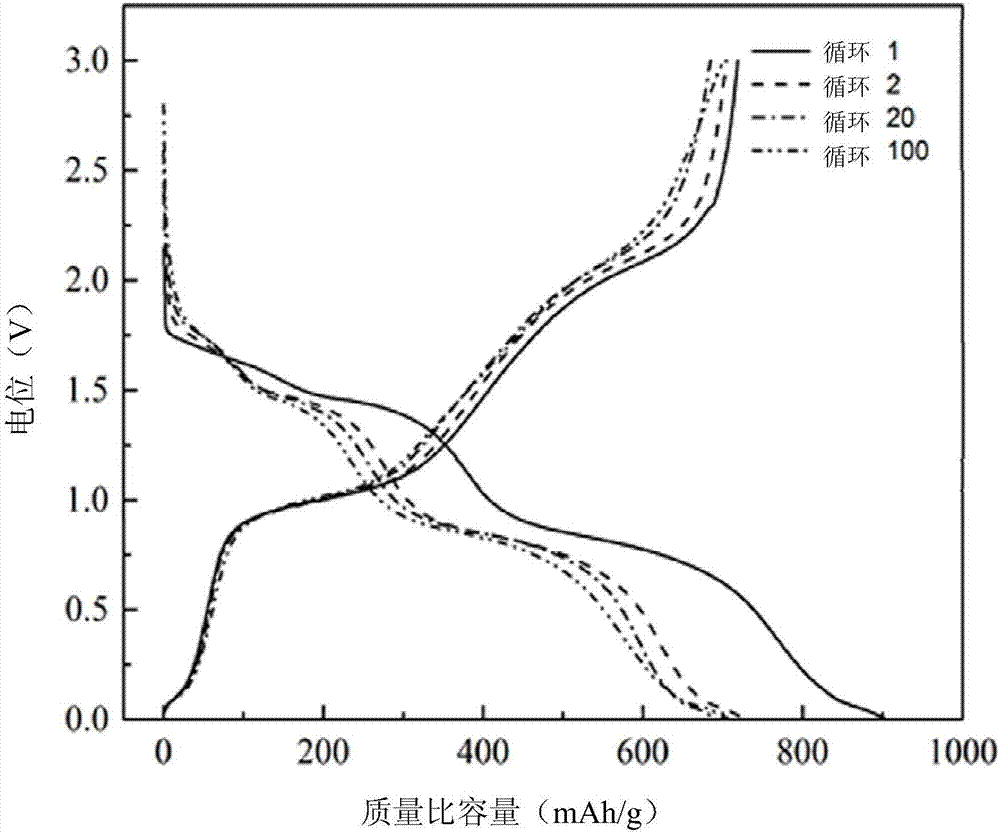

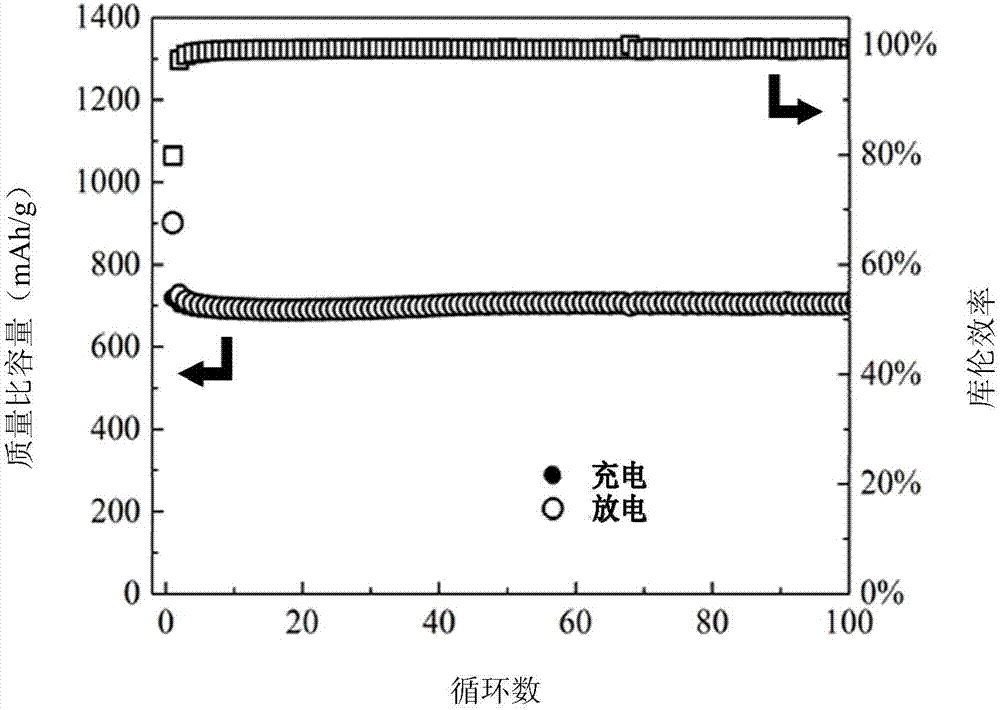

[0055] The antimony sulfide-based negative electrode material (Sb 2 S 3 -Graphite composite material) for lithium-ion batteries: the antimony sulfide-based negative electrode material (Sb 2 S 3 -Graphite composite material), conductive agent (sodium alginate) and binder (Super-P) are mixed and evenly coated on copper foil in a mass ratio of 8:1:1 to make electrode sheets, and dried in vacuum; In an argon atmosphere glove box, lithium metal was used as a counter electrode to assemble a button cell for testing. The test conditions are: the charge and discharge current density is 200mA / g, and the charge and discharge cut-off voltage is 0.01V~3.0V. The cycle perform...

Embodiment 3

[0058] Sb in this example 2 S 3 -The preparation method of the Graphite-based composite material (that is, an antimony sulfide-based negative electrode material with high reversible capacity) is the same as in Example 1, except that the mass ratio of antimony sulfide and graphite is 4:1, the frequency of the motor is 900rpm, and the ball mill The time is 6 hours, adding 2% absolute ethanol whose mass is the total mass of the abrasive.

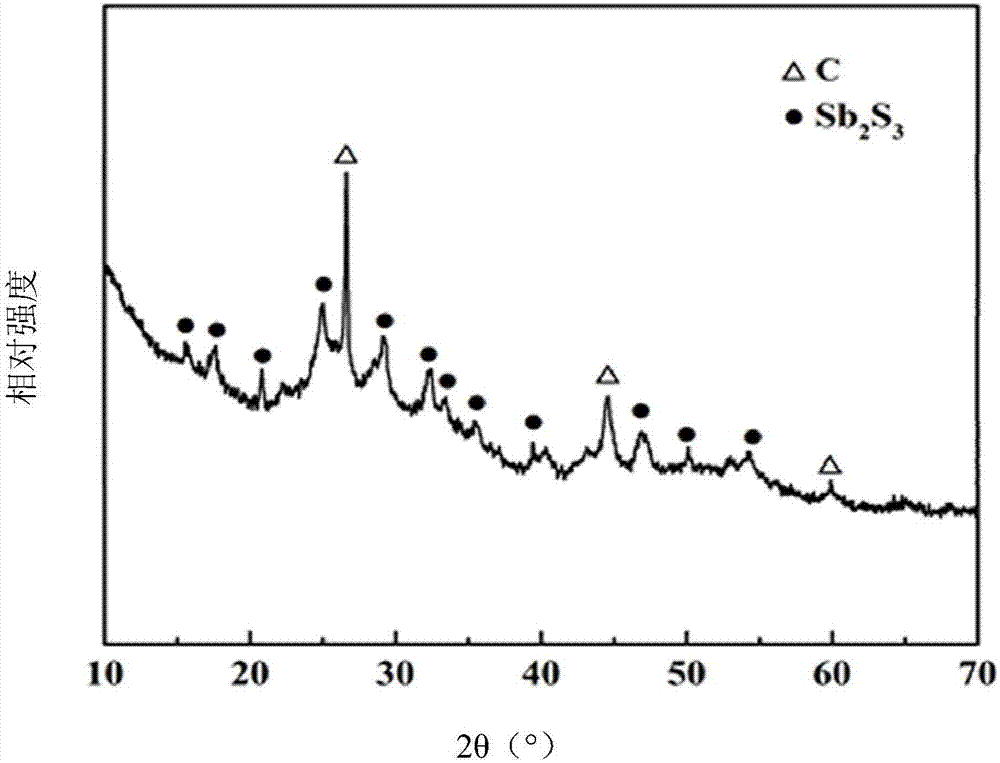

[0059] Figure 6 It is the antimony sulfide-based negative electrode material (Sb 2 S 3 -Graphite composite) XRD patterns.

[0060] The antimony sulfide-based negative electrode material (Sb 2 S 3 -Graphite composite) backscattered SEM image see Figure 7 , as shown in the figure, the antimony sulfide powder is evenly distributed on the carbon matrix after ball milling, and there is no agglomeration phenomenon, which is conducive to giving full play to the high capacity of the antimony sulfide material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Inverse capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com