Electrolyte with thermocuring effect and preparation method of electrolyte

An electrolyte and thermal curing technology, applied in circuits, electrical components, secondary batteries, etc., can solve problems such as the inability to solve the safety problems of lithium-ion batteries, and achieve the effect of improving safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

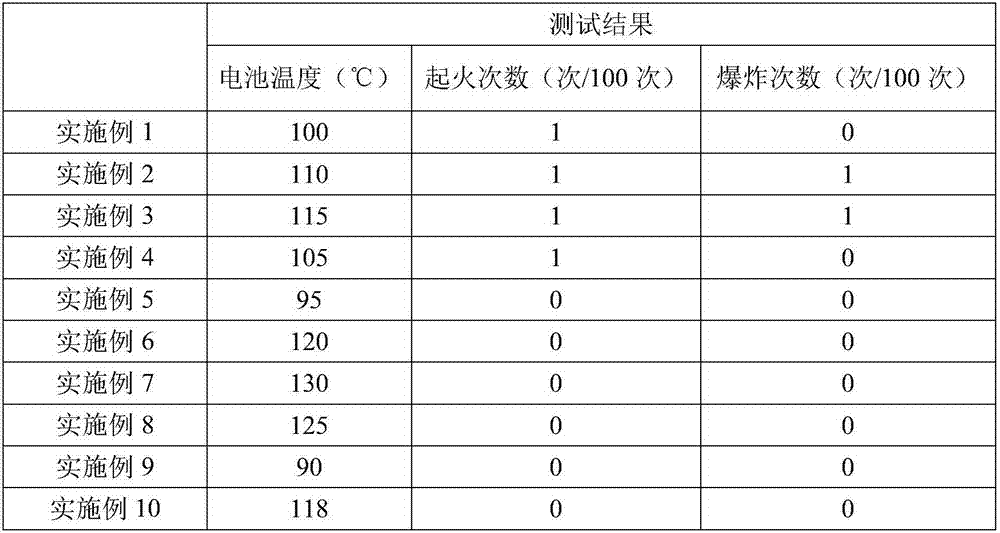

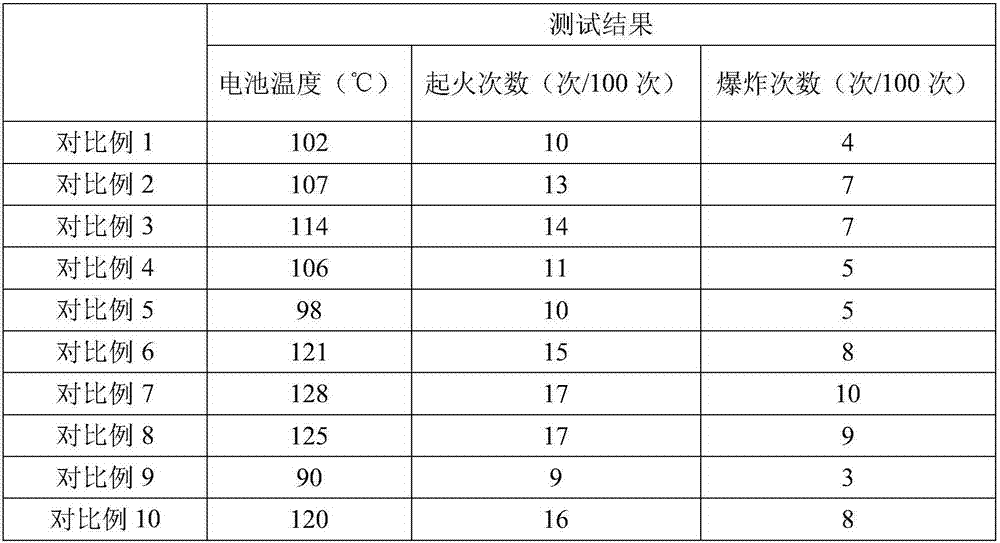

Examples

Embodiment 1

[0023] This embodiment provides an electrolyte with thermal curing effect, including lithium salt, carbonate organic solvent, film-forming additives, polymer monomer and initiator, and the polymer monomer is N,N-4,4 -Diphenylmethane bismaleimide. The mass content of polymer monomer accounts for 1% of the electrolyte. Lithium salt is LiPF 6 , The concentration of lithium salt is 0.8M. The carbonate-based organic solvent is 20% by weight of ethylene carbonate, 40% by weight of ethyl methyl carbonate, and 40% by weight of diethyl carbonate. The mass content of the film-forming additives accounts for 1% of the electrolyte. The film-forming additives are vinylene carbonate and fluoroethylene carbonate. The mass content of the initiator accounts for 0.01% of the electrolyte. The initiator is azobisisobutyronitrile. The preparation method includes the following steps:

[0024] Step 1: Measure out ethyl methyl carbonate and diethyl carbonate in proportions, and pour them into alumi...

Embodiment 2

[0028] The difference from Example 1 is that in this example, the polymer monomer is a bismaleimide oligomer. The mass content of polymer monomer accounts for 3% of the electrolyte. Lithium salt is LiPF 6 , The concentration of lithium salt is 1.0M. The carbonate-based organic solvent is 40% by weight of ethylene carbonate, 20% by weight of ethyl methyl carbonate, and 40% by weight of diethyl carbonate. The mass content of the film-forming additives accounts for 3% of the electrolyte. The film-forming additives are vinylene carbonate and vinyl ethylene carbonate. The mass content of the initiator accounts for 0.03% of the electrolyte. The initiator is azobisisoheptonitrile.

[0029] Others are the same as in Embodiment 1, and will not be repeated here.

Embodiment 3

[0031] The difference from Example 1 is that in this example, the polymer monomer is 1,3-dioxolane. The mass content of polymer monomer accounts for 5% of the electrolyte. Lithium salt is LiPF 6 , The concentration of lithium salt is 1.2M. The carbonate-based organic solvent is 30 wt% of ethylene carbonate, 40 wt% of ethyl methyl carbonate, and 30 wt% of diethyl carbonate. The mass content of the film-forming additives accounts for 5% of the electrolyte. The film-forming additives are vinyl ethylene carbonate and fluoroethylene carbonate. The mass content of the initiator accounts for 0.05% of the electrolyte. The initiator is dimethyl azobisisobutyrate.

[0032] Others are the same as in Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com