Fine particle coal dehydration method

A technology for fine-grained coal and moisture, applied in the field of coal processing, can solve problems such as reducing the moisture of filter cakes, and achieve the effects of reducing the moisture content of filter cakes, improving economic benefits, and increasing calorific value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

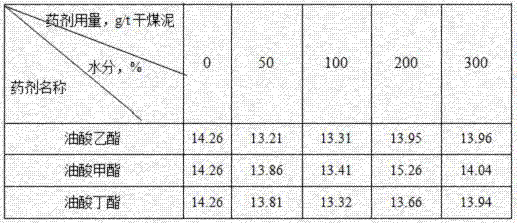

[0018] Ethyl oleate containing oleic acid groups was selected as the filter aid.

[0019] Preparation method of filter aid emulsion: weigh 100g of the drug, add 250ml of water under stirring, and continue stirring for 20-30min to obtain the filter aid emulsion.

[0020] Fine-grained coal pressure filtration test: the ash content of the test sample is 30%, the particle size of the sample is -0.5mm, and the content of -200 mesh is 30%. Prepare pulp with a concentration of 320g / L-350g / L, add the dosage of medicament according to 100, 200, 300, 400, 500g / t dry coal slime, stir for 5min, pour into the cup of the pressurized filter, the bottom of the cup Spread a 200-mesh filter cloth, open the breather valve, and start pressurized filtration. The pressure of the gas introduced is controlled at 0.25 MPa with a pressure control valve. During the filtration process, the pressure in the cup remains basically unchanged during the cake forming stage. After the filter cake is formed, it ...

Embodiment 2

[0024] Methyl oleate containing oleic acid groups was selected as the filter aid.

[0025] The preparation method of the filter aid emulsion and the pressure filtration test process of fine coal are the same as in Example 1. The difference from Example 1 is that the concentration of the prepared slurry is 350g / t dry coal slime, and the dosage of the agent is 100, 200, 300, 400 , 500g / t dry coal slime, the obtained filter cake moisture were 15.93%, 18.72%, 15.84%, 16.67%, 15.17%.

Embodiment 3

[0030] Butyl oleate containing oleic acid group is selected as filter aid.

[0031] The filter aid emulsion preparation method and the fine coal pressurized filtration test process are the same as in Example 1, and the difference from Example 1 is that the gas pressure of the feed is controlled at 0.2MPa by a pressure control valve. When 400, 500g g / t dry coal slime, the moisture content of the obtained filter cake is 15.93%, 17.74%, 17.12%, 16.88, 17.71%, respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com