Triarrhena lutarioriparia biomass fuel

A technology of biomass fuel and carbonized material, which is applied in the direction of biofuel, waste fuel, fuel, etc., can solve the problems of high production cost, low combustion heat, low utilization rate, etc., achieve good hydrophobic performance, increase fixed carbon content, improve The effect of heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

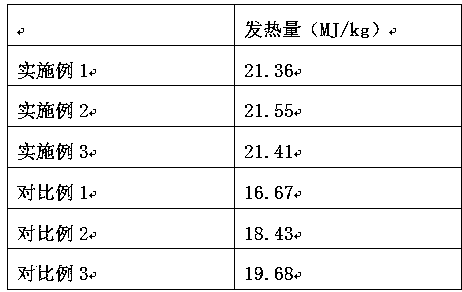

Examples

Embodiment 1

[0020] Disclosed is a Nandi biomass fuel, which is obtained by mixing carbonized material obtained by pulverizing and carbonizing Nandi stalks with corn stalk powder obtained by crushing corn stalks, adding them to a biomass molding machine and pressing them.

[0021] Further, the mixing mass ratio of the carbonized material to the corn stalk powder is 1.2:3.

[0022] Further, the preparation method of the carbonized material is:

[0023] (1) Modification

[0024] Crush the stalks of Nandi to 90 meshes to obtain the powder of Nandi stalks. After soaking the powder of Nandi stalks in a strong oxidizing acid solution with a mass fraction of 3.5% for 2.5 hours, the mixing ratio of the powder of Nandi stalks and the nitric acid solution is 120g: 400mL, then add potassium acetate with a mass of 1.2% to the nitric acid solution, stir at a speed of 200r / min for 2 hours, then filter, wash with water until neutral, and dry in vacuum to obtain modified Nandi stalk powder;

[0025] (2)...

Embodiment 2

[0033] Disclosed is a Nandi biomass fuel, which is obtained by mixing carbonized material obtained by pulverizing and carbonizing Nandi stalks with corn stalk powder obtained by crushing corn stalks, adding them to a biomass molding machine and pressing them.

[0034] Further, the mixing mass ratio of the carbonized material to the corn stalk powder is 1.5:3.

[0035] Further, the preparation method of the carbonized material is:

[0036] (1) Modification

[0037] Crush the stalks of Nandi to 90 meshes to obtain the powder of Nandi stalks. After soaking the powder of Nandi stalks in a strong oxidizing acid solution with a mass fraction of 4% for 2.5 hours, the mixing ratio of the powder of Nandi stalks and the nitric acid solution is 130g: 400mL, then add potassium acetate with a mass of 1.2% to the nitric acid solution, stir at a speed of 200r / min for 2 hours, then filter, wash with water until neutral, and dry in vacuum to obtain modified Nandi stalk powder;

[0038] (2) P...

Embodiment 3

[0046] Disclosed is a Nandi biomass fuel, which is obtained by mixing carbonized material obtained by pulverizing and carbonizing Nandi stalks with corn stalk powder obtained by crushing corn stalks, adding them to a biomass molding machine and pressing them.

[0047] Further, the mixing mass ratio of the carbonized material to the corn stalk powder is 1.3:3.

[0048] Further, the preparation method of the carbonized material is:

[0049] (1) Modification

[0050] Crush the stalks of Nandi to 90 meshes to obtain the powder of Nandi stalks. After soaking the powder of Nandi stalks in a strong oxidizing acid solution with a mass fraction of 3.8% for 2.5 hours, the mixing ratio of the powder of Nandi stalks and the nitric acid solution is 125g: 400mL, then add potassium acetate with a mass of 1.2% to the nitric acid solution, stir at a speed of 200r / min for 2 hours, then filter, wash with water until neutral, and dry in vacuum to obtain modified Nandi stalk powder;

[0051] (2)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com