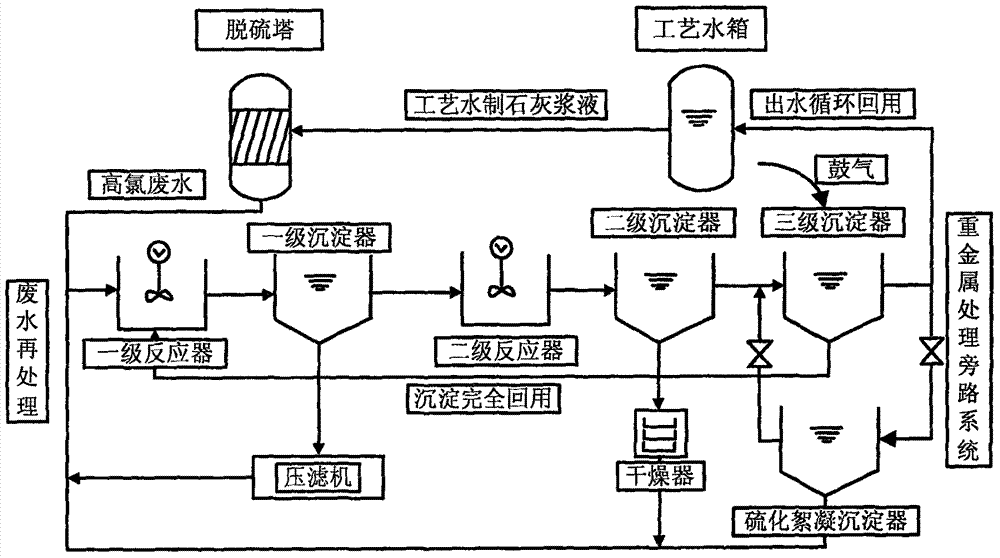

Process flow for deep treatment of desulfurization wastewater

A technology for desulfurization wastewater and process flow, applied in filtration treatment, multi-stage water treatment, water/sewage treatment, etc., can solve the problems of dust pollution, difficulty, high moisture content in solid-liquid separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

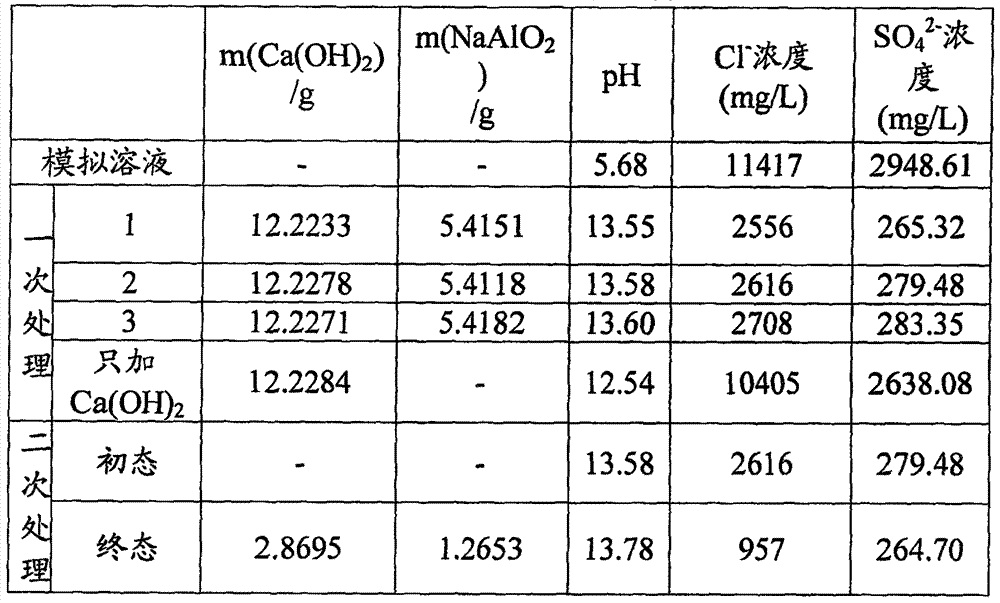

[0040] The process and steps of the present embodiment are as follows: using NaCl and Na 2 SO 4 Prepare a simulated solution of 0.3M chloride ion and 0.03M sulfate concentration:

[0041] (1) First order reaction: according to n(Ca(OH) 2 ):n(NaAlO 2 ):n(Cl - +SO 4 2- )=5:2:1, add the corresponding mass of calcium source and aluminum source into 100mL simulated solution, stir evenly, isolate the air, place in a 40-degree water bath heating oscillator and shake for 2 hours, and perform solid-liquid separation after uniform reaction. Three parallel experiments were performed, and the quality of the reagents is shown in Table 1.

[0042] After the simulated solution treated by the above method was analyzed for water quality, it was found that the treated simulated solution system Cl - The removal rate reached 77%, SO 4 2- 90.53% was removed and the pH of the solution was above 13.50.

[0043] Control experiment, in same solution system, only add calcium hydroxide of same...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com