Health-care solid state dairy product

A dairy product and solid-state technology, which is applied in the field of health-care solid dairy products, can solve problems such as the inability to guarantee stable quality, reduce the benefit function of milk, and lose the activity of bacterial flora, and achieve the effects of protecting gastric mucosa, flexible eating methods, and increasing nutritional functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

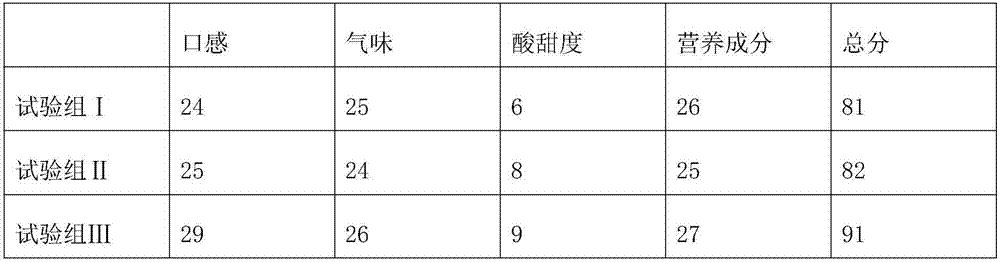

Embodiment 1

[0020] The ratio of raw materials used in this example is: 8 parts of pure milk, 6 parts of chickpeas, 1 part of trehalose, 1 part of fructooligosaccharide, 1 part of lactic acid bacteria, 0.5 part of hawthorn, 0.5 part of wolfberry, 0.5 part of Poria cocos superfine powder, 2 parts of superfine powder of Hericium erinaceus, 18 parts of distilled water, lactic acid bacteria mixed with plant lactic acid bacteria and bifidobacteria at a mass ratio of 1:1.

[0021] The preparation process is as follows:

[0022] (1) Select chickpeas with full grains and wash them, boil them in 80°C distilled water for 30 minutes, take them out after ripening and drain them, peel them and cool to room temperature, add fructooligosaccharides, and add distilled water for grinding; take fresh hawthorn 1. Wash wolfberries and blanch them in distilled water at 80°C for 3 minutes, remove and drain, cool to room temperature, and then mix and squeeze the juice;

[0023] (2) Superfinely pulverize the Pori...

Embodiment 2

[0029] The ratio of raw materials used in this example is: 12 parts of pure milk, 10 parts of chickpea, 2 parts of trehalose, 2 parts of fructooligosaccharide, 2 parts of lactic acid bacteria, 1.0 part of hawthorn, 1.0 part of Chinese wolfberry, 1.0 part of Poria cocos superfine powder, 4 parts of Hericium erinaceus superfine powder, 30 parts of distilled water, lactic acid bacteria mixed with plant lactic acid bacteria and Lactobacillus bulgaricus at a mass ratio of 1:1.

[0030] The preparation process is as follows:

[0031] (1) Select chickpeas with full grains, wash them, boil them in distilled water at 100°C for 30 minutes, take them out after ripening and drain them, peel them and cool them to room temperature, add fructooligosaccharides and distilled water for grinding; take fresh hawthorn 1. Wash wolfberries and blanch them in distilled water at 80°C for 8 minutes, remove and drain, cool to room temperature, and then mix and squeeze the juice;

[0032] (2) Superfinel...

Embodiment 3

[0038] The ratio of raw materials used in this example is: 10 parts of pure milk, 10 parts of chickpea, 2 parts of trehalose, 2 parts of fructooligosaccharide, 2 parts of lactic acid bacteria, 0.5 part of hawthorn, 0.5 part of wolfberry, 1.0 part of Poria cocos superfine powder, 4 parts of superfine powder of Hericium erinaceus, 30 parts of distilled water, and lactic acid bacteria are formed by mixing plant lactic acid bacteria and Lactobacillus casei in a mass ratio of 1:1.

[0039] The preparation process is as follows:

[0040] (1) Select chickpeas with plump grains, wash them, boil them in 80°C distilled water for 30 minutes, take them out after ripening and drain them, peel them and cool to room temperature, add fructooligosaccharides, and add distilled water for grinding; take fresh hawthorn 1. Wash the wolfberries and blanch them in distilled water at 80°C for 5 minutes, remove and drain, cool to room temperature, and then mix and squeeze the juice;

[0041] (2) Super...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com