Method for maintaining or generating positive-monovalent rhodium catalyst active center

A rhodium catalyst and active technology, applied in the field of maintaining or generating positive monovalent rhodium catalyst active centers, can solve the problems of low carbonylation reaction activity, inability to maintain active centers, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

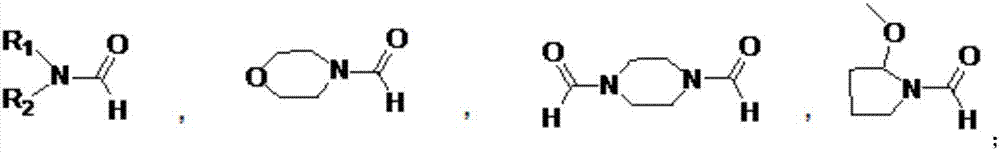

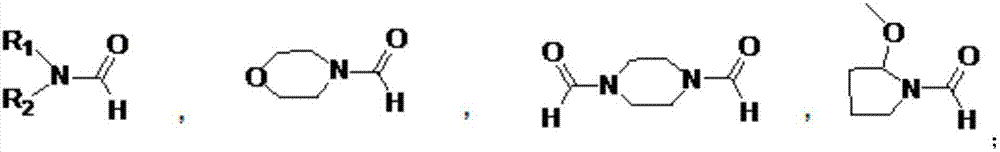

Method used

Image

Examples

Embodiment 1

[0038] The positive trivalent trans-[Rh(CO) of the rhodium mass content of the prepared 5000ppm 2 I 4 ] - Add the mass content of ruthenium [Ru(CO) of 5000ppm 3 I 3 ] - , the water content in the system is 4%, adding lithium iodide, the mass content of lithium is about 3360×10 -6 , the rest is acetic acid solution, replaced with nitrogen to ensure that there is no CO in the system, heated at 120°C for 4h, and carried out NMR 13 C NMR analysis, trans-[Rh(CO) 2 I 4 ] - Completely disappear, all generate positive monovalent cis-[Rh(CO) 2 I 2 ] - , δ184.2, J Rh-CO = 72Hz.

Embodiment 2

[0040] RhI 3 solid added to 13 [Ru( 13 CO) 3 I 3 ] - In the solution, wherein the mass content of rhodium is 2000ppm, the water content in the system is 4%, and lithium iodide is added, and the mass content of lithium is about 3360×10 -6 , the rest is acetic acid solution, replaced with nitrogen to ensure that there is no 13 CO, heated at 120°C for 4h, and carried out NMR 13 C NMR analysis, only the cis-[Rh( 13 CO) 2 I 2 ] - Generation, δ183.5, J Rh-CO = 72Hz.

Embodiment 3

[0042] The trans-[Rh(CO) of the positive trivalent rhodium mass content of the prepared 1250ppm 2 I 4 ] - Mo(CO) added to a Mo mass content of 5000ppm 6 , the water content in the system is 4%, adding lithium iodide, the mass content of lithium is about 3360×10 -6 , the rest is acetic acid solution, replaced with nitrogen to ensure that there is no CO in the system, heated at 120°C for 4h, and carried out NMR 13 C NMR analysis, trans-[Rh(CO) 2 I 4 ] - Completely disappear, all generate positive monovalent cis-[Rh(CO) 2 I 2 ] - , δ184.0, J Rh-CO = 72Hz.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com