Waste extrusion blow molding system

An extrusion blow molding and waste technology, which is applied in the field of mold parts processing, can solve the problems of many and complex product processes, high product scrap rate, appearance defects, etc., and achieve the effect of high cost performance, no secondary pollution, and beautiful appearance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

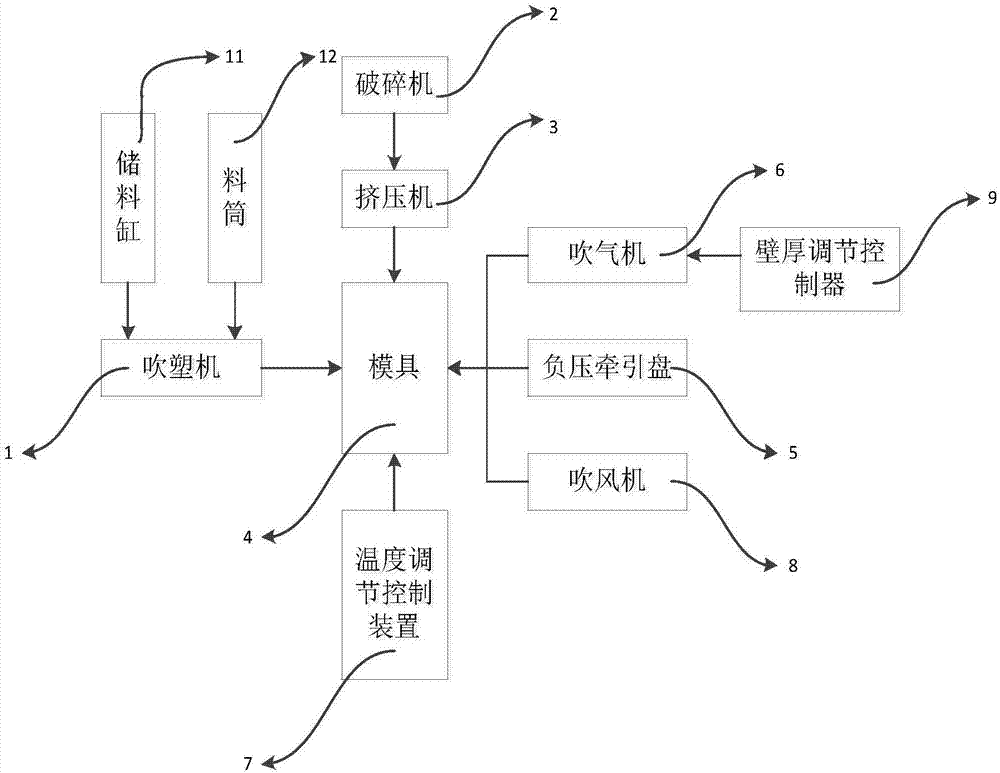

[0028] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. refer to figure 1 , figure 2 , the present invention provides a waste material extrusion blow molding system, including a blow molding machine 1, characterized in that it also includes:

[0029] Crusher 2, used for crushing and recycling the waste after removing impurities;

[0030] An extruder 3, connected to the crusher 2, is used to melt the material and extrude the parison;

[0031] Mold 4 has a cavity and is in a mold clamping state;

[0032] Negative pressure traction disc 5 is arranged at the bottom of the mold 4, and is used to provide downward negative pressure traction, so that the parison can be quickly filled into the cavity of the mold 4;

[0033] The air blower 6 is used to blow air to the inside of the parison, so that the outer surface of the parison is bonded to the inner surface of the mold cavity of the mold 4;

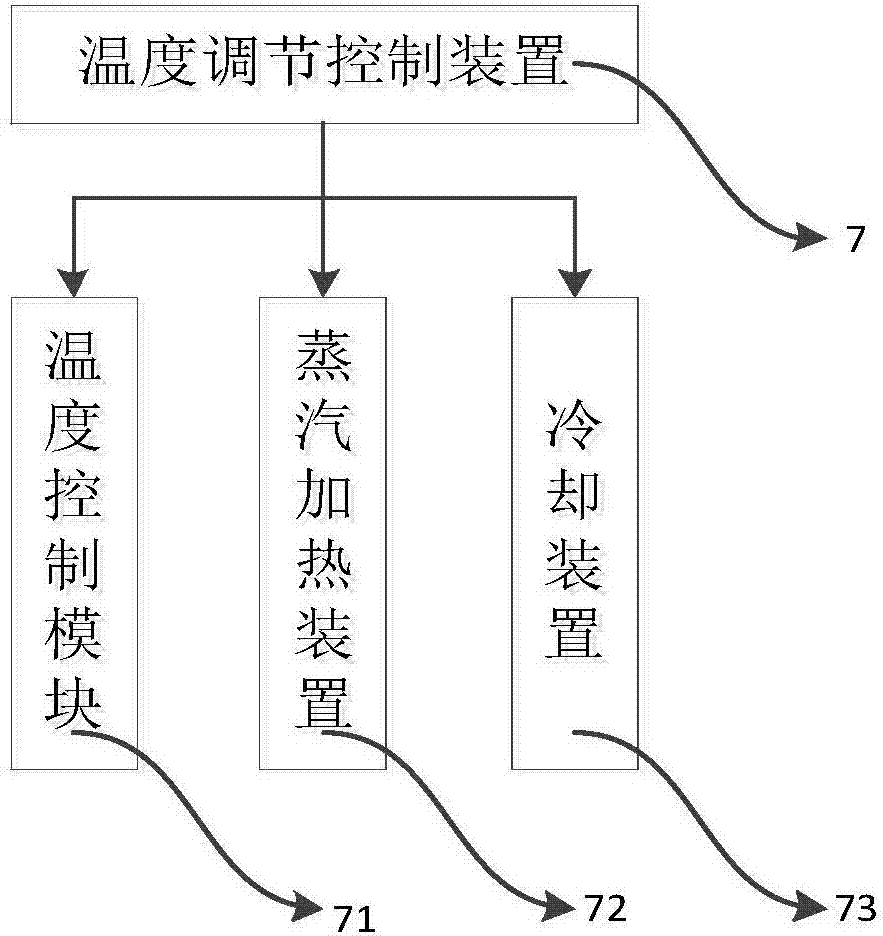

[0034] The tempe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com